Swing type sealing feeder

A feeder and feeding technology, which is applied in the field of feeders, can solve the problems of breakage of fragile materials, vibration feeders without sealing function, etc., and achieve the effect of adjustable feeding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

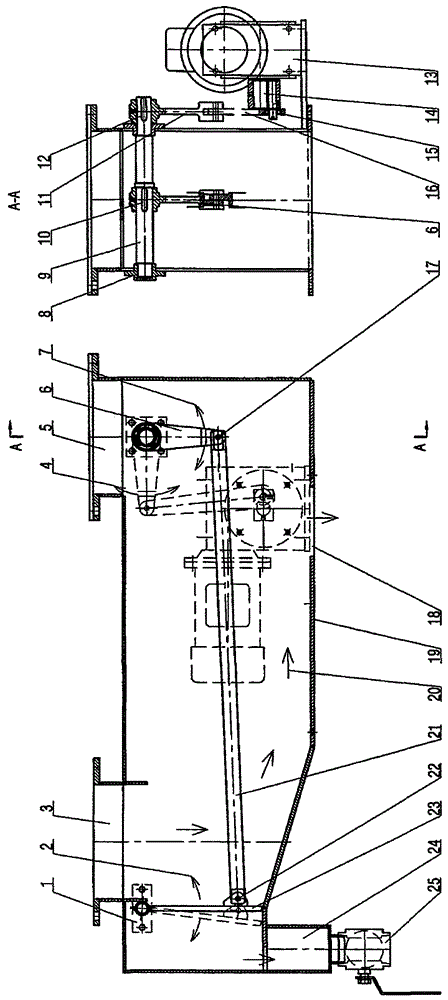

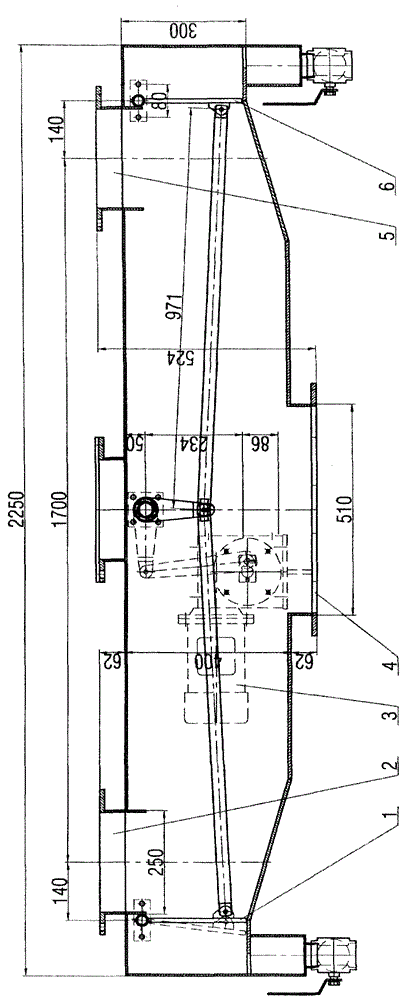

[0009] The geared motor 13 drives the crank 14 to rotate, the crank drives the connecting rod 16 outside the chamber to reciprocate up and down, the connecting rod 16 drives the rocker 11 outside the chamber to swing up and down along the arrow 4, and the rocker outside the chamber 11 drives the rocker inside the chamber through the rocker shaft 9 6 swings horizontally along the arrow 7, and the rocker 6 in the cavity drives the swing door 23 to swing horizontally along the arrow 2 through the connecting rod 21 in the cavity. The material enters the cavity from the material inlet 3, and is discharged from the cavity from the material outlet 18 along the arrow 20 under the swinging action of the swing door 23. During the whole process, the material and the outside air are effectively isolated by the casing 19; the material is squeezed and damaged to a small extent during the whole process. During the working process, a very small amount of material will enter the buffer bin 24, an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap