Screening and crushing bucket

A bucket and screening technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the problems that the screening and crushing work cannot be carried out, the price is expensive, etc., and achieve the effect of uniform force, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

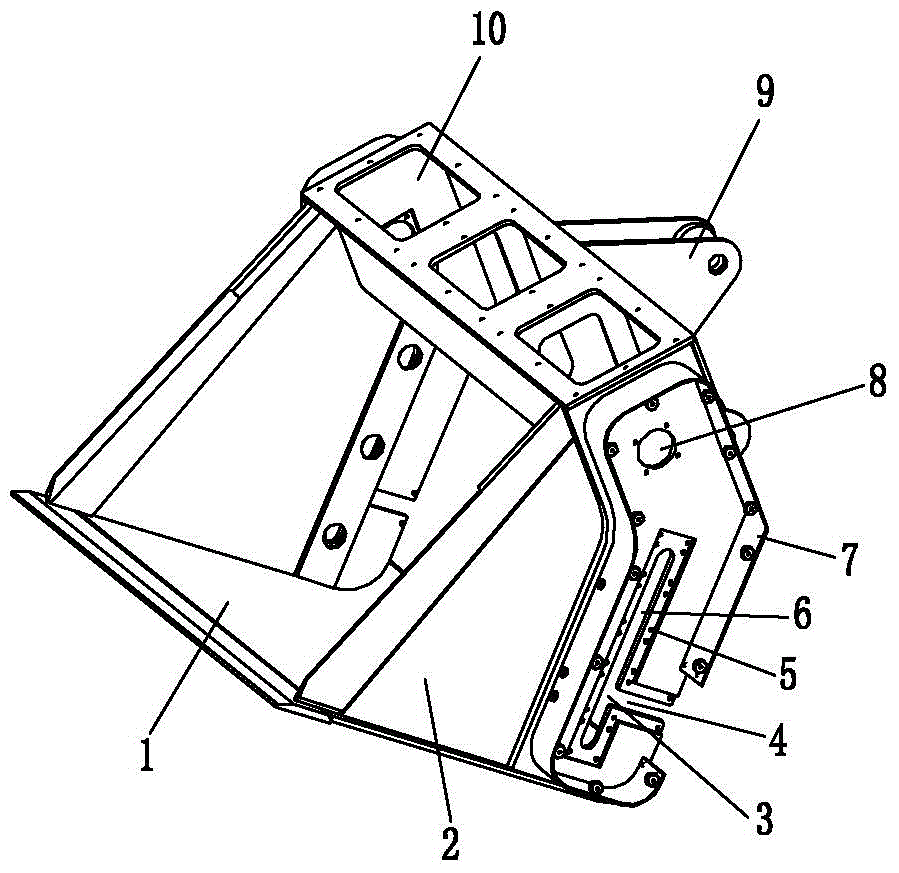

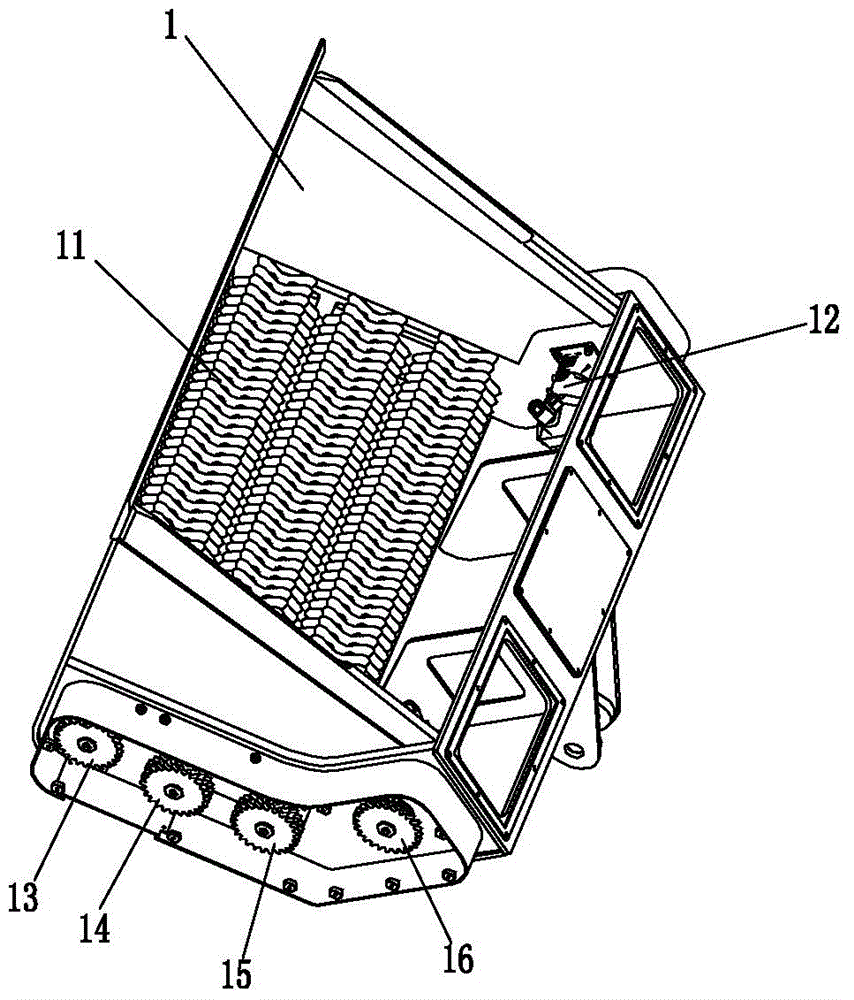

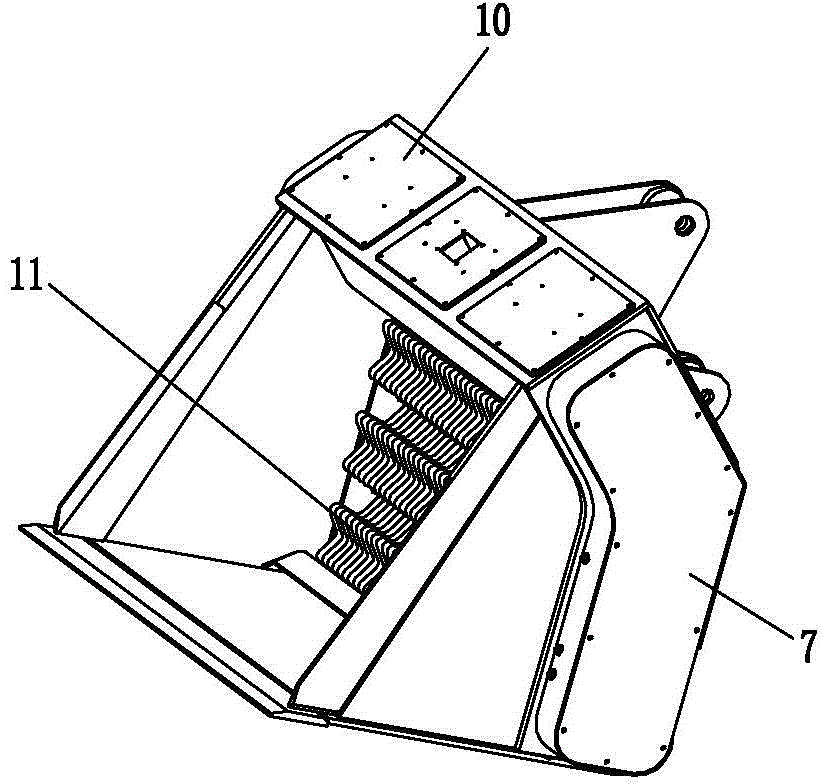

[0014] Such as Figure 1 to Figure 5 As shown, the screening and crushing bucket of the present invention includes a bucket body 1, a hydraulic motor 12, a screening and crushing mechanism 11 arranged in the bucket body 1, and a transmission box connected to the outside of one of the side walls 2 of the bucket body 1. 7. The transmission mechanism arranged in the transmission box 7.

[0015] The bucket body 1 is a bucket-shaped structure with a hollowed out back, so that the material can fall out of the bucket body 1 immediately after screening and crushing, which is convenient for improving the screening and crushing efficiency. The bucket body 1 includes two oppositely arranged side walls 2, and the lower side of the two side walls 2 is provided with a T-shaped groove 3 for installing a screening and crushing mechanism 11. The T-shaped groove 3 includes a horizontal groove 6 and a connecting horizontal groove. The vertical groove 4 on the lower side of the groove 6, the upper

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap