Hydraulic lifting wall brushing machine manually controlled by sprockets and chains

A technology of hydraulic lifting and sprocket chain, applied in construction, building structure and other directions, can solve problems such as cost increase, paint waste, waste of paint and paint, etc., to improve the speed of wall painting, reduce costs, and save paint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The lifting wall painting machine of the present invention will be further described below in conjunction with the accompanying drawings.

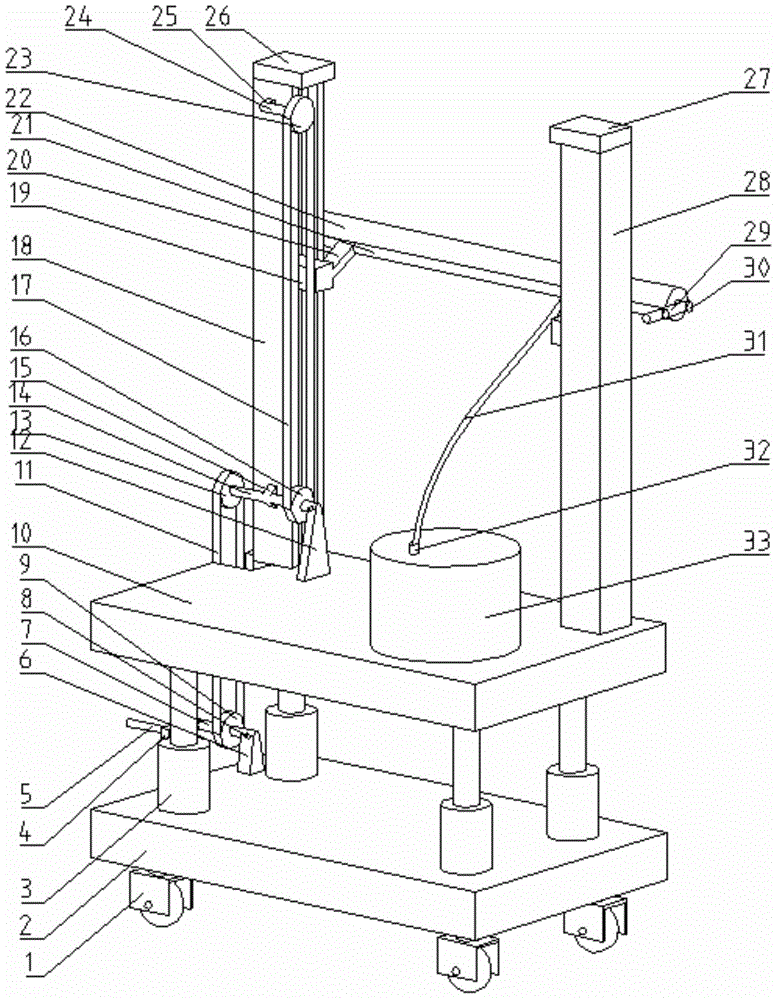

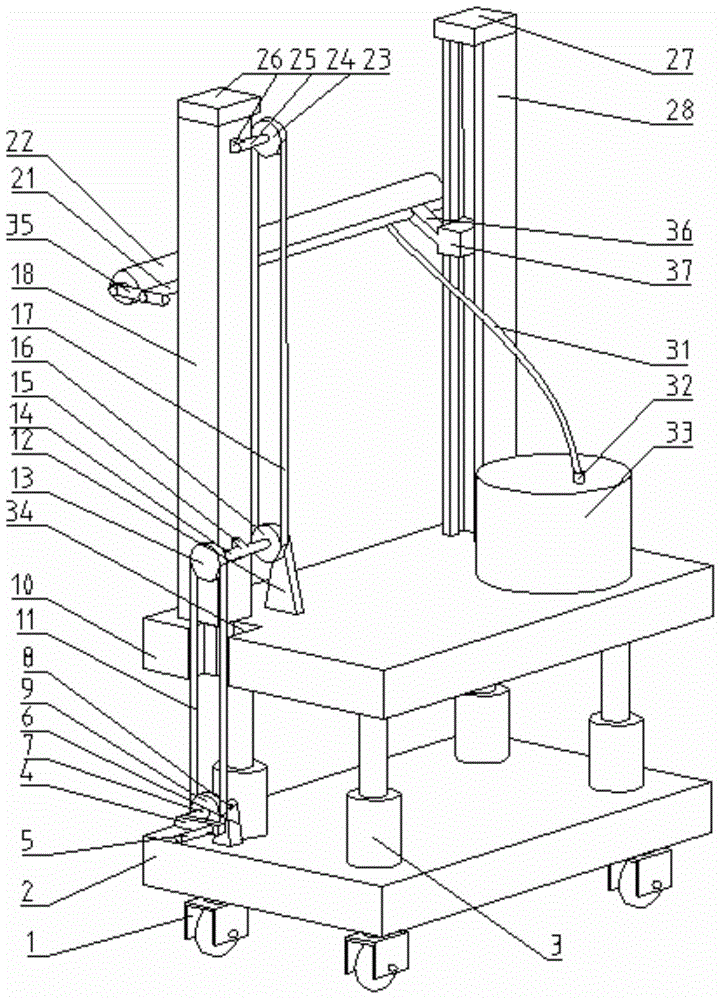

[0015] Such as figure 1 and figure 2 As shown, two symmetrically arranged left uprights 18 and right uprights 28 are fixed on the second base 10, and the left upright 18 and the right upright 28 are respectively provided with a slidingly fitted left slider 19 and a right slider on the opposite inner sides. 37. The bottom of left column 18 is provided with second drive sprocket 16 and first driven sprocket 13, and second drive sprocket 16 and first driven sprocket 13 are installed on the second axle 14, and second axle 14 passes bearing Installed on the second fixed block 12 and the third fixed block 15, the second fixed block 12 is fixed on the second base 10, the third fixed block 15 is fixed on the left column 18; the top of the left column 18 is provided with a second slave The driven sprocket 23 and the second driven sprocket 2

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap