Detection device and method of bolt load and pad compacting force of flange connection

A technology of gasket pressing and detecting device, applied in measuring device, force/torque/work measuring instrument, measuring torque/torsion force during tightening, etc., can solve the problem that there is no way to accurately apply bolt pre-tightening force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

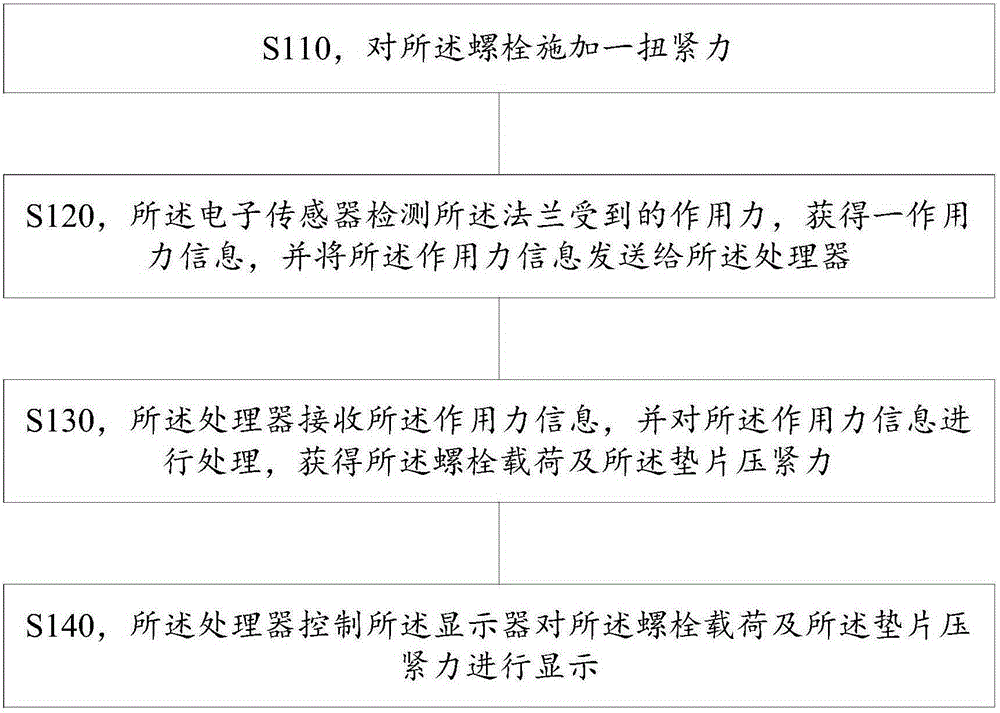

[0020] The embodiment of the present application provides a detection device and method for flange connection bolt load and gasket compression force, which solves the problem that the bolt pretightening force determined by the method in the prior art may not necessarily obtain the predicted internal pressure. Gasket compression force, and there is no way to accurately apply the technical problem of bolt preload.

[0021] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

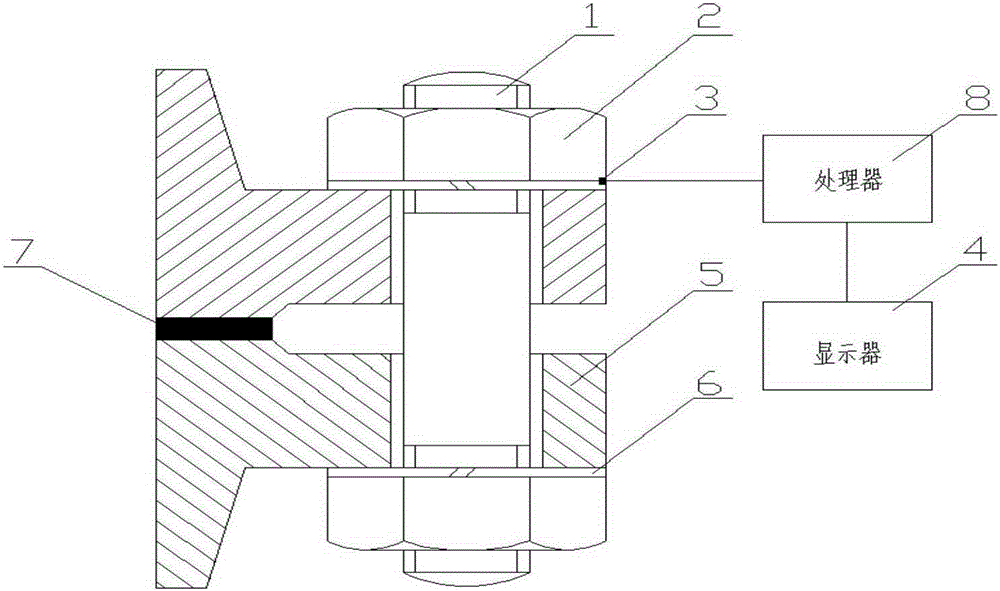

[0022] The application provides a detection device for flange connection bolt load and gasket compression force, the detection device is used to detect the bolt load and gasket compression force on the flange connection device, and the flange connection device includes a bolt , two nuts fixed at both ends of the bolt, two flanges fixed on the bolt and located between the two nuts, and a gasket arranged betwe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap