Exhausting wave-resistant water stop device

A water-stopping device and anti-wave technology, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve problems such as economic loss, bombing, damage, etc., to reduce floating resistance, reduce resistance, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0024] This embodiment provides an anti-wave and water-proof device used on an underwater vehicle. The device is connected to the exhaust pipe of the vehicle. Anti-surge, anti-rainwater and water-stop function when submerged in water for a moment, so as to ensure the safety of the aircraft.

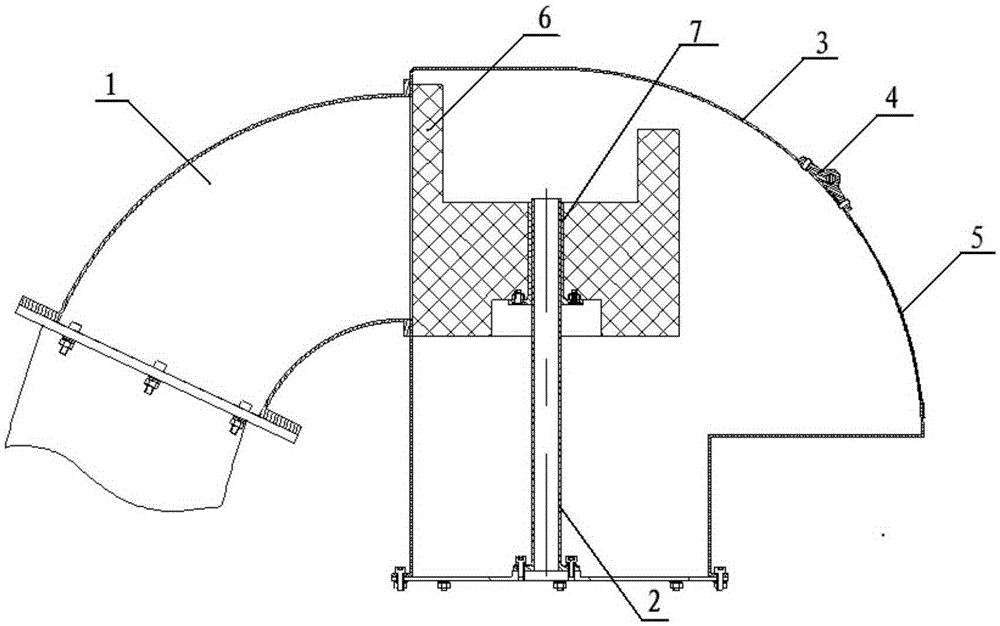

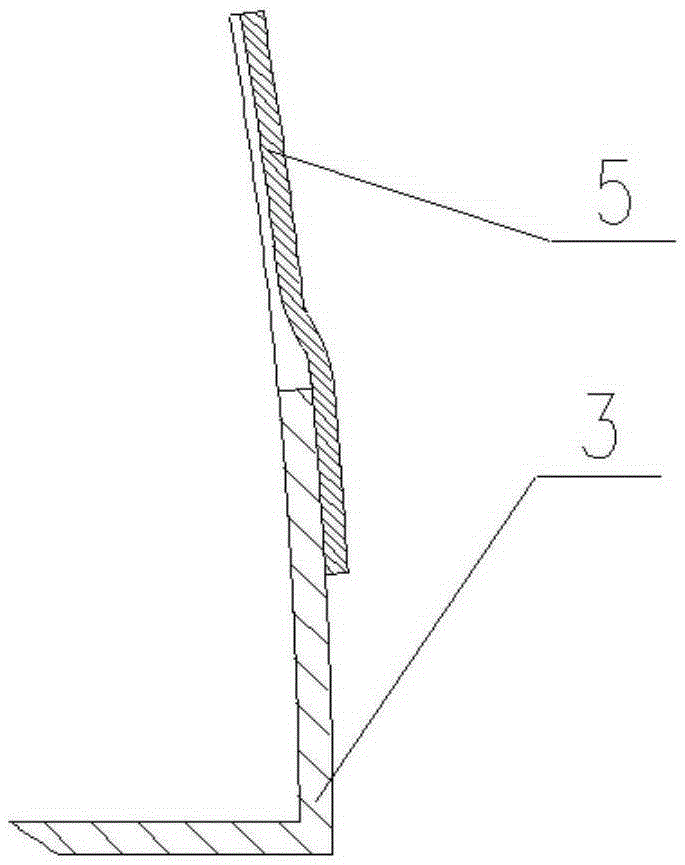

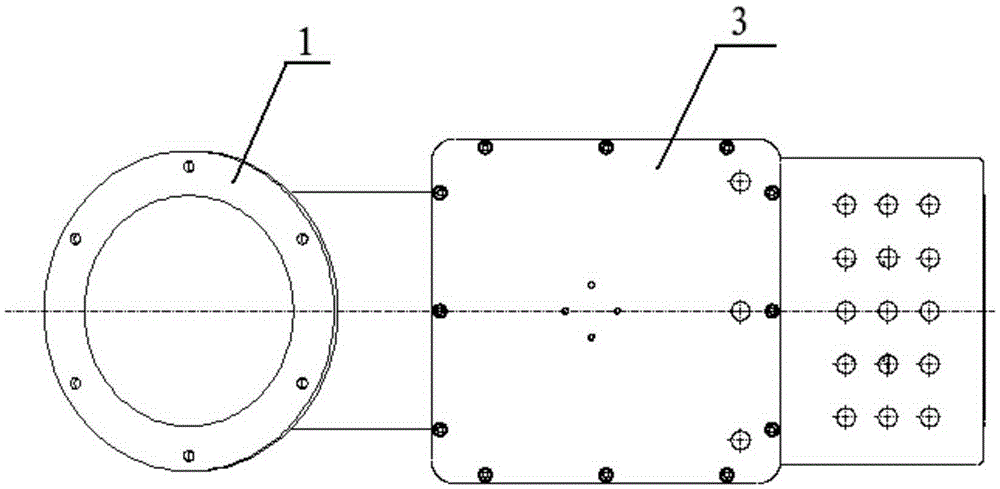

[0025] The structure of the exhaust and anti-wave anti-water device is as follows: figure 1 As shown, it includes an exhaust elbow 1, an anti-wave shell 3, a sleeve 7, a slide pipe 2, a water baffle 5 and a float 6, and the peripheral equipment is an exhaust pipe 8 of an underwater vehicle.

[0026] Since the exhaust temperature of the aircraft is as high as 450°C, and the overall weight is required to be light; therefore, the exhaust elbow 1, the sliding pipe 2, the anti-wave shell 3, the water retaining 5 and the sleeve 7 are all made of light-weight high-temperature-

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap