Traction bracket of foam plate surface napping machine

The technology of foam board and hair pulling machine is applied in the field of traction bracket, which can solve the problems of occupying space, unable to pull the board, large volume, etc., and achieve the effects of reducing production cost, simple production process and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the drawings.

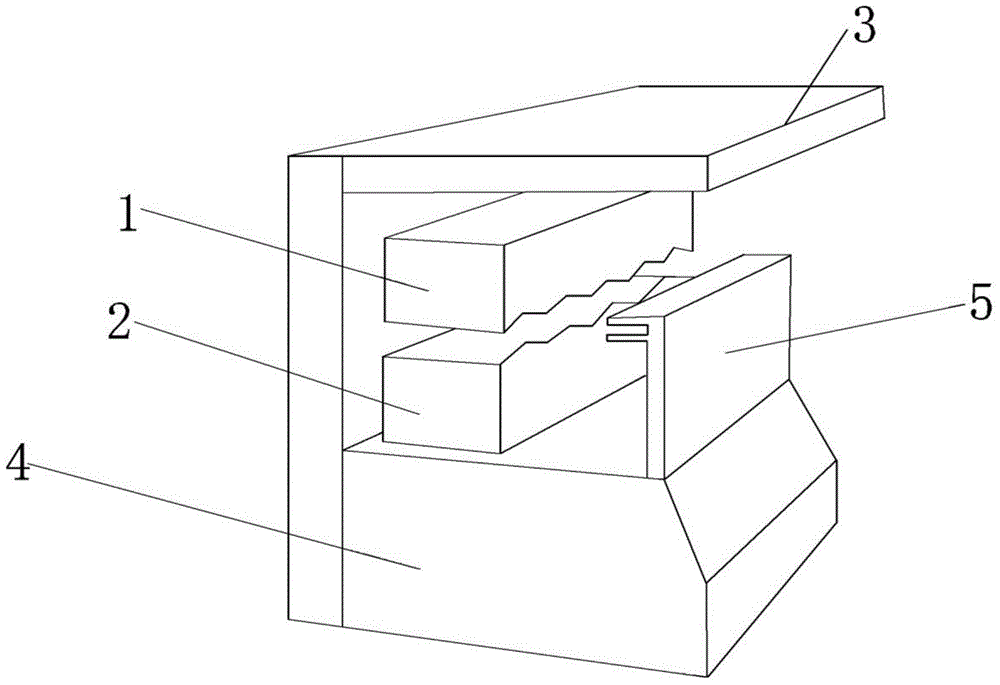

[0014] Such as figure 1 As shown, a traction support for a foam board surface napping machine is characterized in that it includes a host 4, a top baffle 3, a planer set, a traction support 5 and a motor set;

[0015] The motor unit includes a top motor and a traction motor; it is placed in the top baffle 3, and the traction motor is located at the bottom of the host 4; the traction motor is connected to the traction support 5,

[0016] The traction support 5 includes a movable plate and two traction clips; the movable plate is placed on the platform of the host 4, and the traction motor controls the movable plate to move back and forth along the foam board movement direction; the movable plate has a traction clip fixing groove; The clamp is fixed on the side of the movable plate near the planer group and forms an "F" shape with the movable plate.

[0017] The traction clamp includes an uppe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap