Bogie for mounting traction motor in flexible suspending manner

A traction motor and elastic suspension technology, applied in the field of vehicle bogies, can solve the problem of large stress at the connection between the motor mounting seat and the beam steel pipe, and achieve the effect of reducing the external size and weight, and having a simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

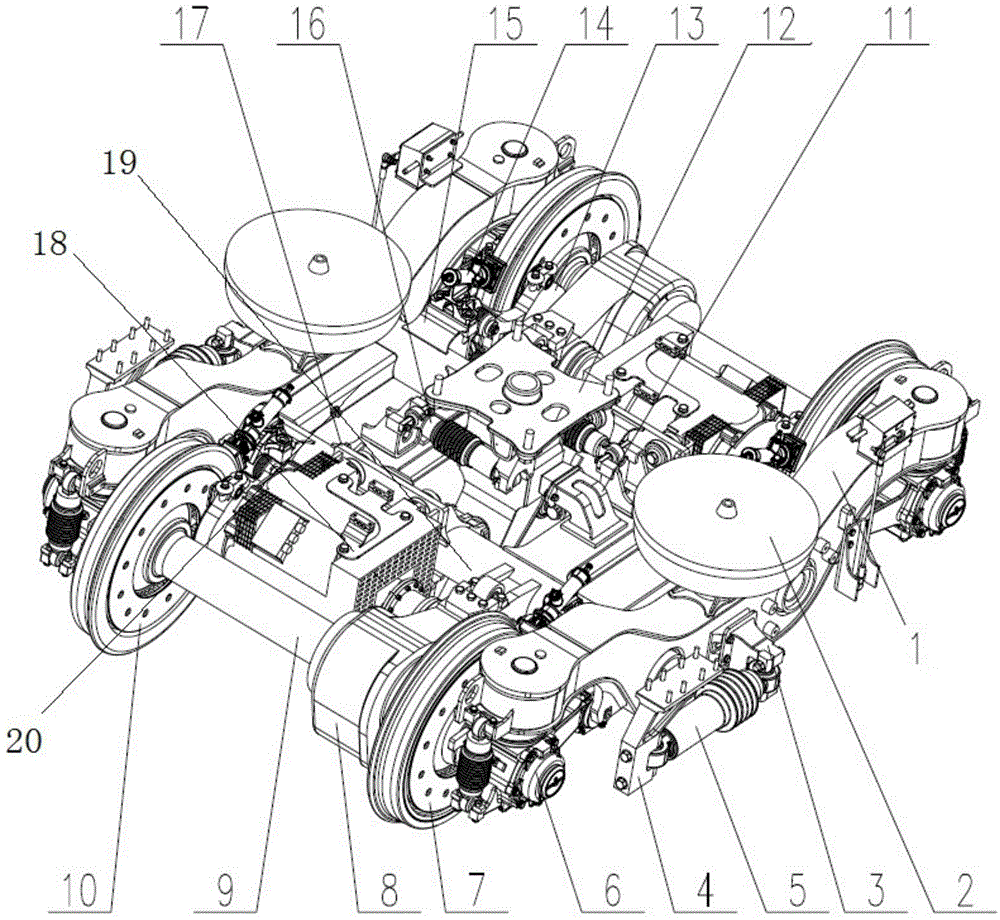

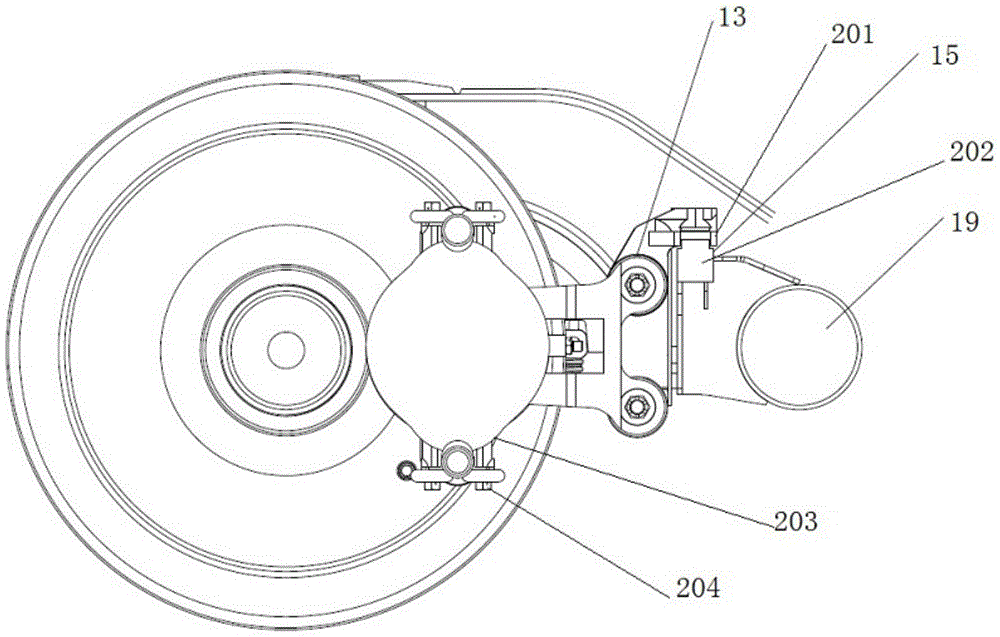

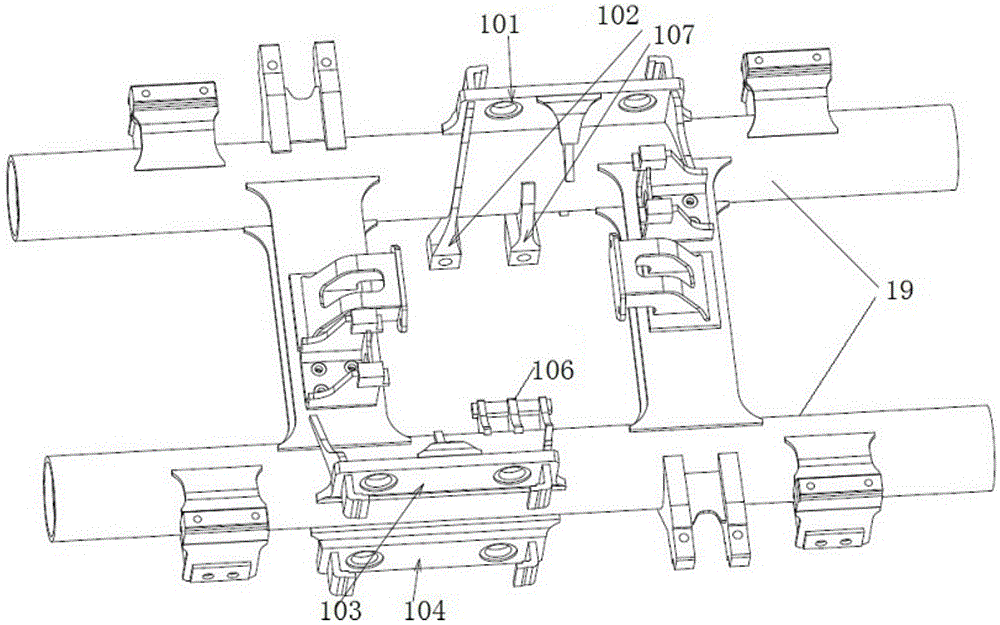

[0027] Such as figure 1 Shown: 1. Side beam; 2. Air spring; 3. Anti-snaking damper mounting seat (bogie side) 4. Anti-snaking damper mounting seat (car body side); 5. Anti-snaking damper; 6. Axle box; 7. Wheel; 8. Gearbox; 9. Axle; 10. Wheel brake disc; 11. Lateral stopper; 12. Center pin; 13. Foundation braking device; 14. Tread cleaning device 15. Brake mount; 16. Transverse shock absorber; 17. Motor mount; 18. Traction motor; 19. Beam; 20. Air chamber.

[0028] The bogie with traction motor elastically suspended according to the present invention includes side beams, air springs, anti-snaking shock absorber mounting seats, anti-snaking shock absorbers, axle boxes, wheels, gearboxes, axles, and wheel-mounted brake discs , Lateral stopper, center pin, foundation brake device, tread cleaning device, brake mounting seat, lateral shock absorber, motor mou

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap