Molding drum

A technology of forming drum and spindle, applied in tires, other household appliances, household appliances, etc., can solve the problems of poor production efficiency of forming drum, and achieve the effect of ensuring quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

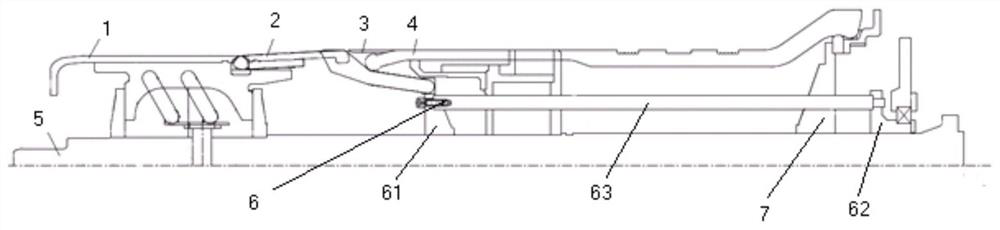

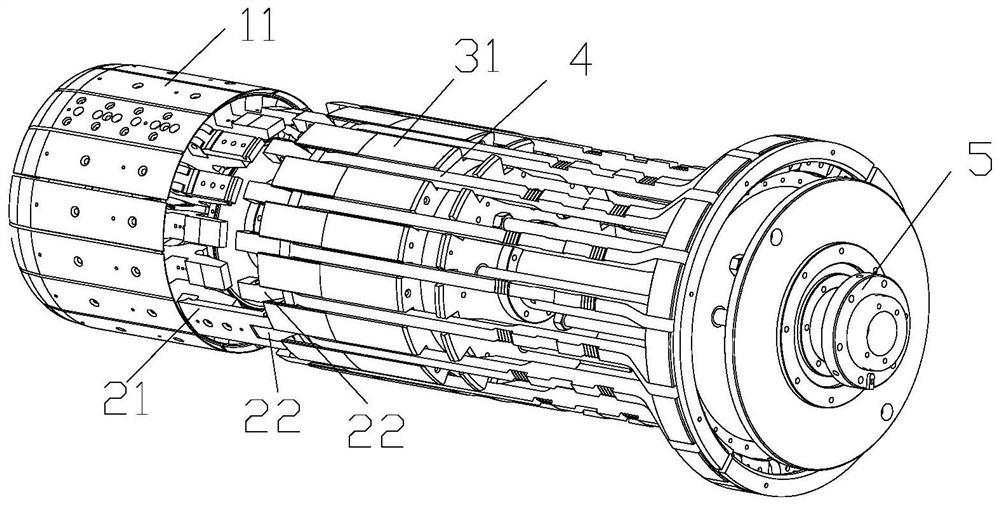

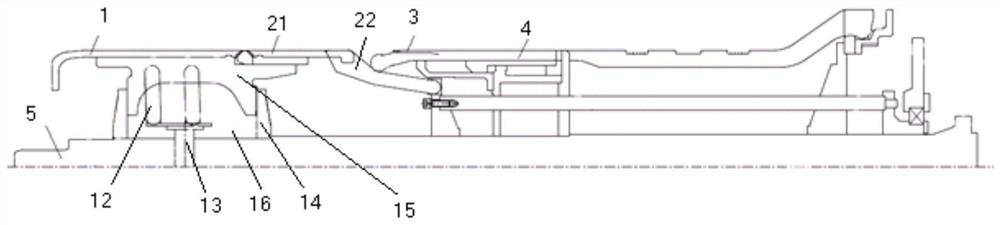

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] As recorded in the background technology, in the existing air spring forming equipment, the drum used in the secondary process is mainly used, and the realization of most functions requires manual assistance. The drum used in the secondary process needs to position the large and small steel rings separately, so it is easy to cause deformation of the embryo and affect the quality of the air spring, and most of the actions in the secondary process need to be completed manually, resulting in low production efficiency and poor product quality. The secondary forming process has low lamination precision, low degree of automation, and excessive manual intervention, which seriously affects the form

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap