Excavator armrest box supporting stabilizing structure

A technology for stabilizing the structure and armrest box, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of inaccurate operation, easy shaking of the box, trouble, etc., to achieve uniform force, stable structure, and not easy to shake. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings.

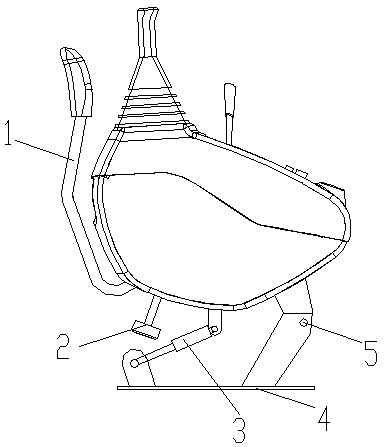

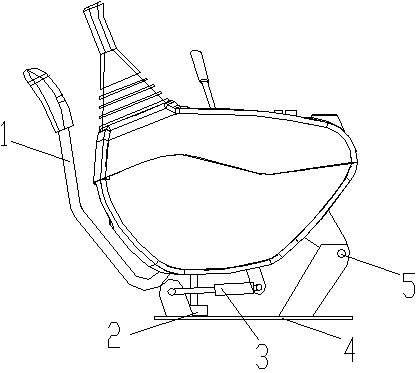

[0012] Such as figure 1 with figure 2 As shown, an excavator armrest box supporting and stabilizing structure includes a handle 1, a gas spring 3, a bottom plate 4, and a shaft 5. The handle 1 is set on the armrest box, and the gas spring 3 is set on the bottom plate 4 at the lower part of the armrest box, and the shaft 5 is connected The bottom plate 4 and the front end of the armrest box; also include the support column 2; the number of support columns 2, the gas spring 3, the bottom plate 4, and the shaft 5 are two, which are installed on the left and right sides of the armrest box, so that the armrest box can be evenly stressed. It is not easy to shake, and when the operator is operating, the operation is accurate, and there will be no wrong operation; the support column 2 is installed at the middle and rear of the lower part of the armrest box to provide sufficient support when the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap