Method and apparatus for producing nonwoven fabrics

A technology of non-woven fabrics and equipment, applied in the field of non-woven fabrics, can solve problems such as water accumulation, non-woven fabric volume reduction, interference, etc., and achieve the effects of reducing energy consumption, avoiding damage, and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

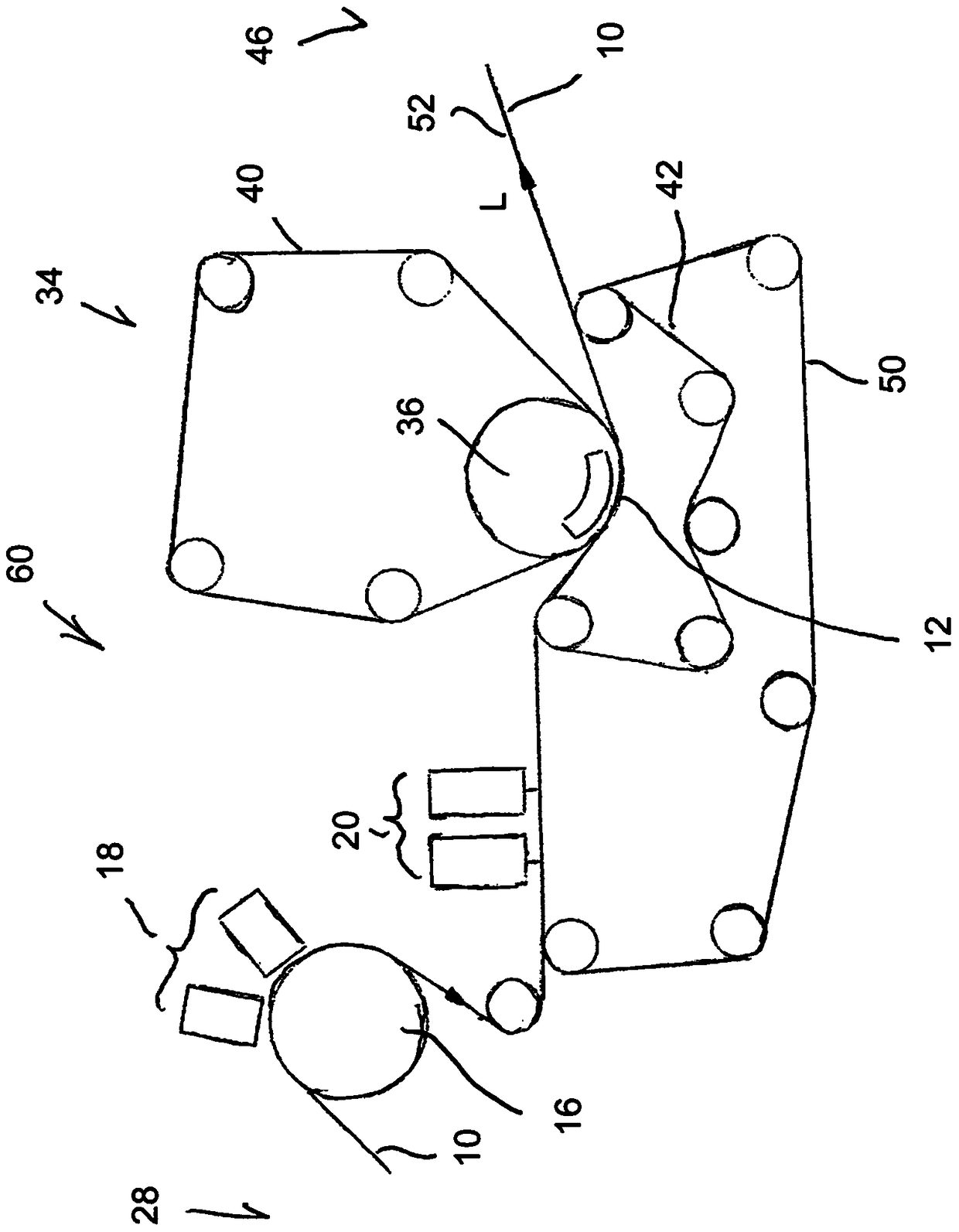

[0077] figure 1 The purely schematically shown device 60 for producing a nonwoven comprises a former for forming the nonwoven, designated only by reference numeral 28, and for supplying the nonwoven formed from the formed nonwoven. The web 52 is further dewatered in the belt press section 34 .

[0078] The nonwoven is formed in the former 28 according to a nonwoven forming method or any combination of different such methods. In this case, it can be formed in particular by dry methods, wet methods and / or extrusion methods.

[0079] The formed nonwoven is consolidated, for example, by means of at least one (in the present exemplary embodiment, for example two) reinforcement devices 18 , 20 which preferably operate according to the hydroentanglement method and here comprise, for example, each two nozzles. As can be seen below, hydroentanglement is not mandatory in every case. The consolidated nonwoven web 52 is then further dewatered.

[0080] The belt press section 34 compris

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap