Shielding structure for medium-voltage cable

A shielding structure and cable shielding technology, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, cables, etc., can solve problems such as not making corresponding requirements, and achieve increased shielding cross-sectional area, improved shielding effect, Effect of reducing quantity to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

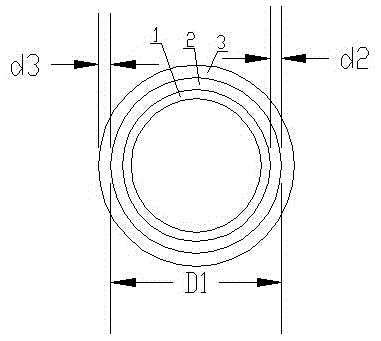

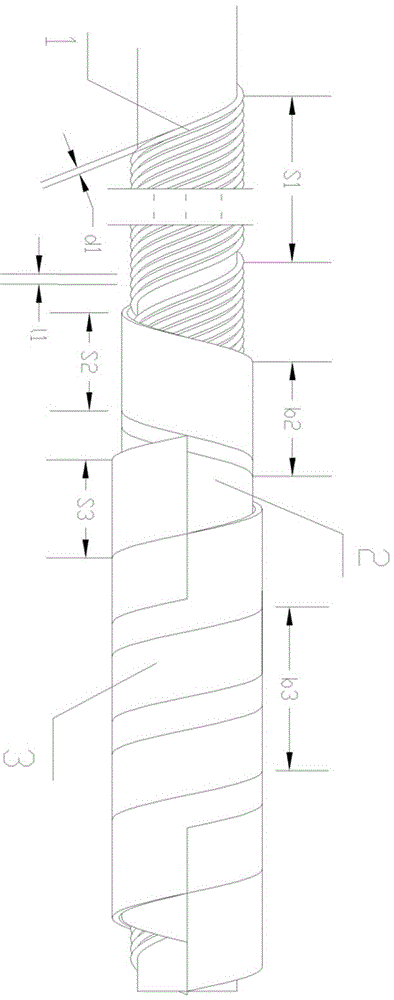

[0037] A medium-voltage cable shielding structure, the medium-voltage cable is a 26 / 35 / 40kv XLPE insulated power cable, its specification: the number of cores × section (mm2) is 1 × 500, and its conductor structure: number / unit The diameter (n / mm) is 61 / 3.20, and the outer diameter (mm) before shielding is 51.3. The shielding structure consists of three layers, which are sequentially provided with a copper wire sparse winding layer, a copper tape wrapping layer, and a non-woven fabric wrapping layer from the inside to the outside;

[0038] The copper wire sparse winding layer is formed by sparsely winding copper wires with a number of 60 and a diameter of 1.03mm. The spacing between the copper wires is 2.3 mm, and the open pitch of the copper wires is 213.6 mm.

[0039] The copper tape shielding layer is formed by wrapping a copper tape with a thickness of 0.1 mm and a width of 40 mm. The wrapping direction of the copper tape is leftward, and the outer diameter of the

Embodiment 2

[0042] A medium-voltage cable shielding structure, the medium-voltage cable is a 26 / 35 / 40kv XLPE insulated power cable, its specification: the number of cores × section (mm2) is 1 × 630, and its conductor structure: number / unit The diameter (n / mm) is 61 / 3.65, and the outer diameter (mm) before shielding is 54.9; the shielding structure consists of three layers, from the inside to the outside, there are copper wire sparse winding layer, copper tape wrapping layer, no Spun cloth around the wrapping.

[0043] The copper wire sparse winding layer is formed by copper wires with a number of 64 and a diameter of 1.03 mm. The copper wires are sparsely wound in the right direction, and the outer diameter of the sparse winding is 57.0 mm. Every two adjacent The spacing between the copper wires is 3.1 mm, and the open pitch of the copper wires is 247.9 mm.

[0044] The copper tape shielding layer is formed by wrapping a copper tape with a thickness of 0.1 mm and a width of 40 mm.

Embodiment 3

[0047] A medium-voltage cable shielding structure, the medium-voltage cable is a 26 / 35 / 40kv XLPE insulated power cable, its specification: the number of cores × section (mm2) is 1 × 500, and its conductor structure: number / unit The diameter (n / mm) is 61 / 3.20, and the outer diameter (mm) before shielding is 51.3. The shielding structure consists of three layers, which are sequentially provided with a copper wire sparse winding layer, a copper tape wrapping layer, and a non-woven fabric wrapping layer from the inside to the outside;

[0048] The copper wire sparse winding layer is formed by sparsely winding copper wires with a number of 60 and a diameter of 1.03mm. The distance between the copper wires is 4 mm, and the pitch of the copper wires is 320.4 mm.

[0049] The copper tape shielding layer is formed by wrapping a copper tape with a thickness of 0.1 mm and a width of 40 mm. The wrapping direction of the copper tape is leftward, and the outer diameter of the copper

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap