Fixing structure for decorative material layer

A decorative material and fixed structure technology, applied in building construction, covering/lining, construction, etc., can solve problems such as inconvenient installation and complex structure, achieve the effect of simple and convenient use, ingenious and light structure, and reduce the chance of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

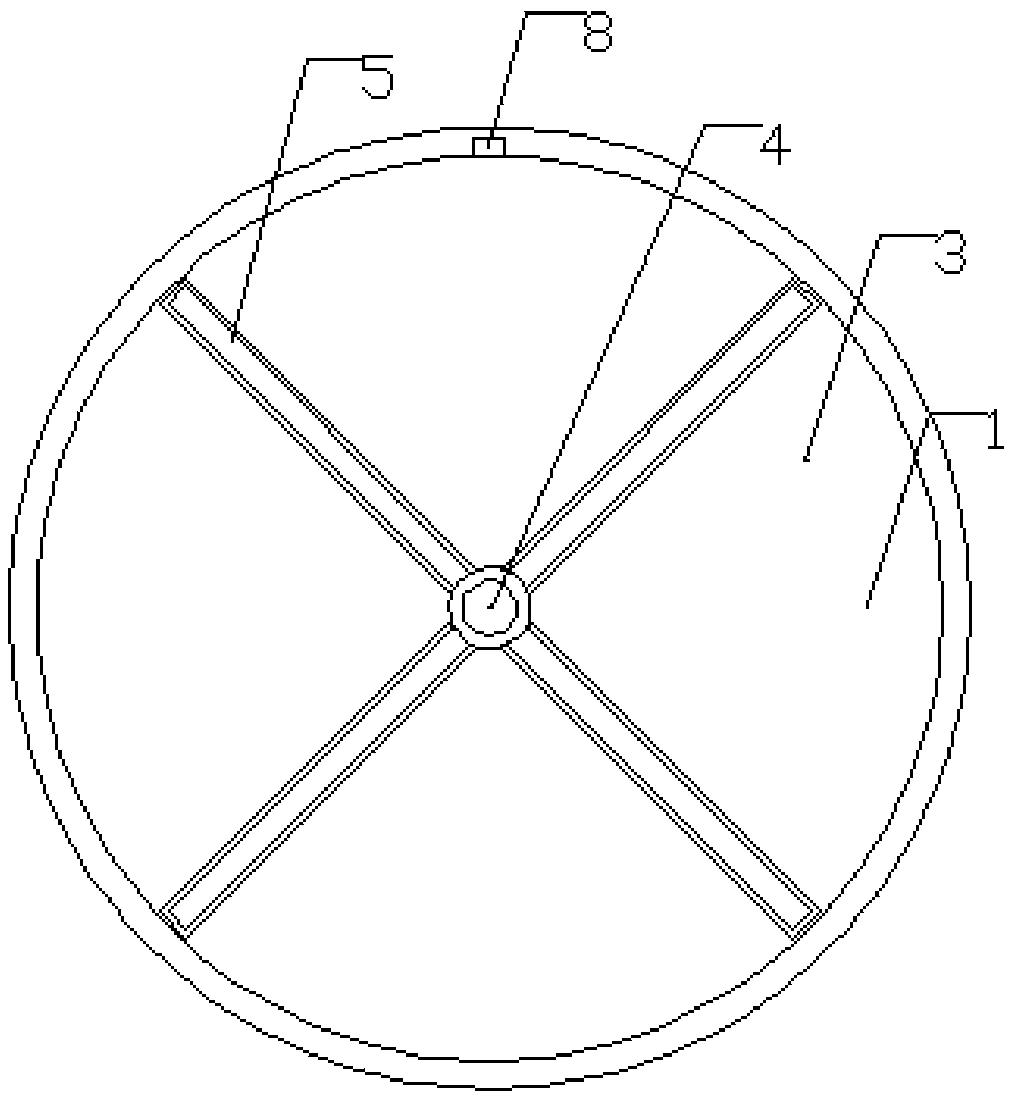

[0032] Such as figure 1 , figure 2 and image 3 As shown, a fixed structure of a decorative material layer includes: a building exterior wall 1 and a circular decorative material layer 2 matching the building exterior wall 1, and the building exterior wall 1 is provided with a The groove 3 of the layer 2 is provided with a threaded installation groove 4 on the inner wall in the center of the groove 3, and a plurality of card grooves 5 are also arranged around the installation groove 4 in the groove 3. The decorative material layer 2 The side matching the groove 3 is provided with a card strip 6 matching the card groove 5, and a receiving block 7 is movably connected in the center of the decorative material layer 2, and it can move axially along the receiving block 7 so that The clamping strip 6 is engaged with the clamping groove 5 in one-to-one correspondence, and the end of the receiving block 7 close to the groove 3 is provided with an external thread that matches the mo...

Embodiment 2

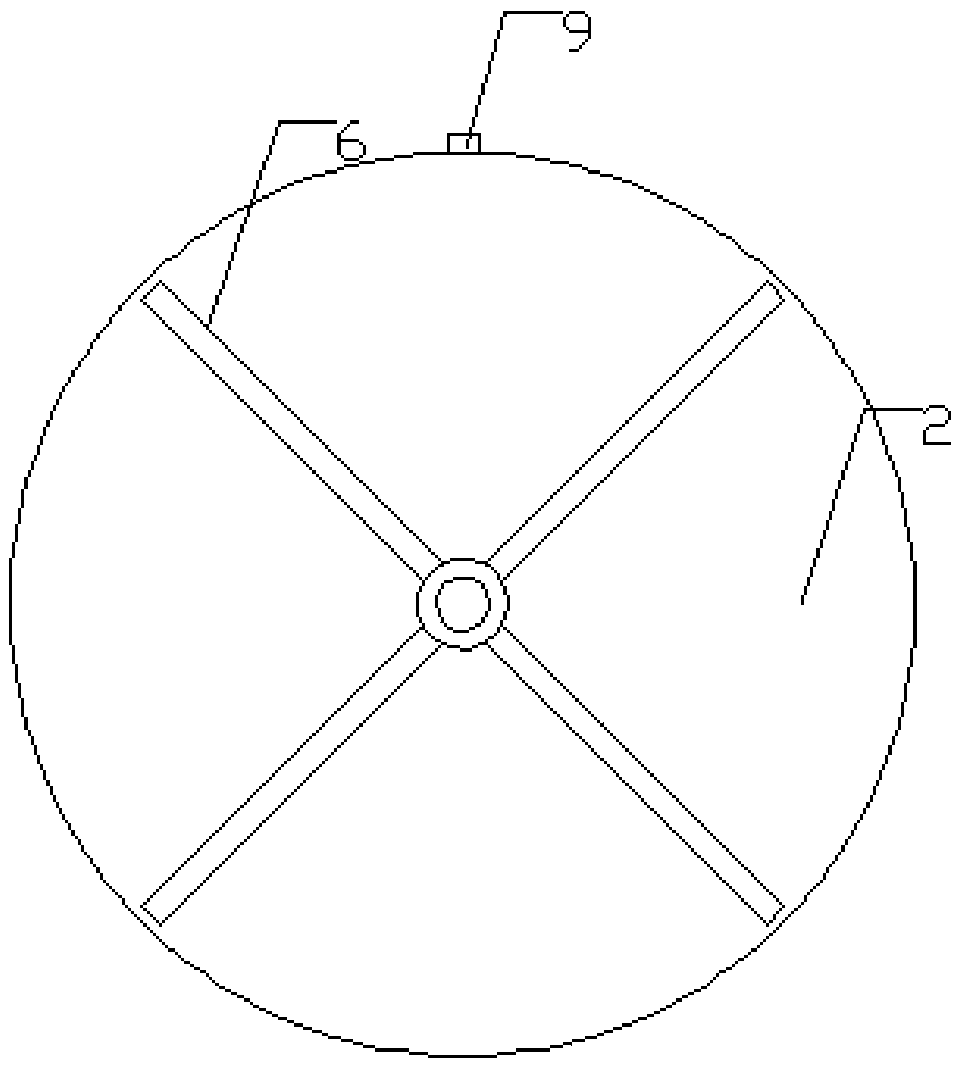

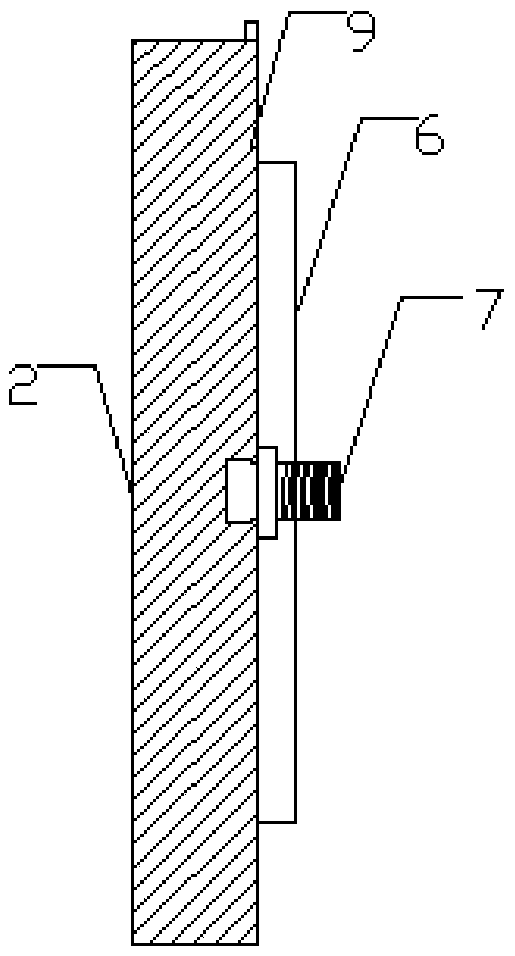

[0036] Such as Figure 4 , Figure 5 and Figure 6 As shown, a fixed structure of a decorative material layer includes: a building exterior wall 1 and a circular decorative material layer 2 matching the building exterior wall 1, and the building exterior wall 1 is provided with a The groove 3 of the layer 2 is provided with a threaded installation groove 4 on the inner wall in the center of the groove 3, and a plurality of card grooves 5 are also arranged around the installation groove 4 in the groove 3. The decorative material layer 2 The side matching the groove 3 is provided with a card strip 6 matching the card groove 5, and a receiving block 7 is movably connected in the center of the decorative material layer 2, and it can move axially along the receiving block 7 so that The clips 6 are snapped together with the slots 5 one by one, the end of the receiving block 7 close to the groove 3 is provided with an external thread matching the installation groove 4, and the deco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap