Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Grout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grout is a dense fluid which is used to fill gaps or used as reinforcement in existing structures. Grout is generally a mixture of water, cement, and sand and is employed in pressure grouting, embedding rebar in masonry walls, connecting sections of pre-cast concrete, filling voids, and sealing joints such as those between tiles. Common uses for grout in the household include filling in tiles of shower floors and kitchen tiles. It is often color tinted when it has to be kept visible and sometimes includes fine gravel when being used to fill large spaces (such as the cores of concrete blocks). Unlike other structural pastes such as plaster or joint compound, correctly mixed and applied grout forms a water resistant seal.

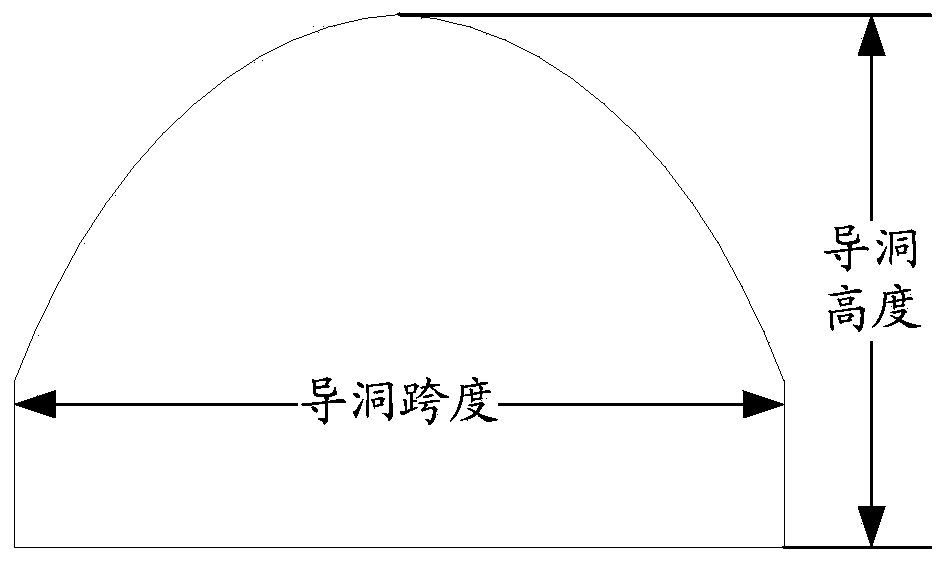

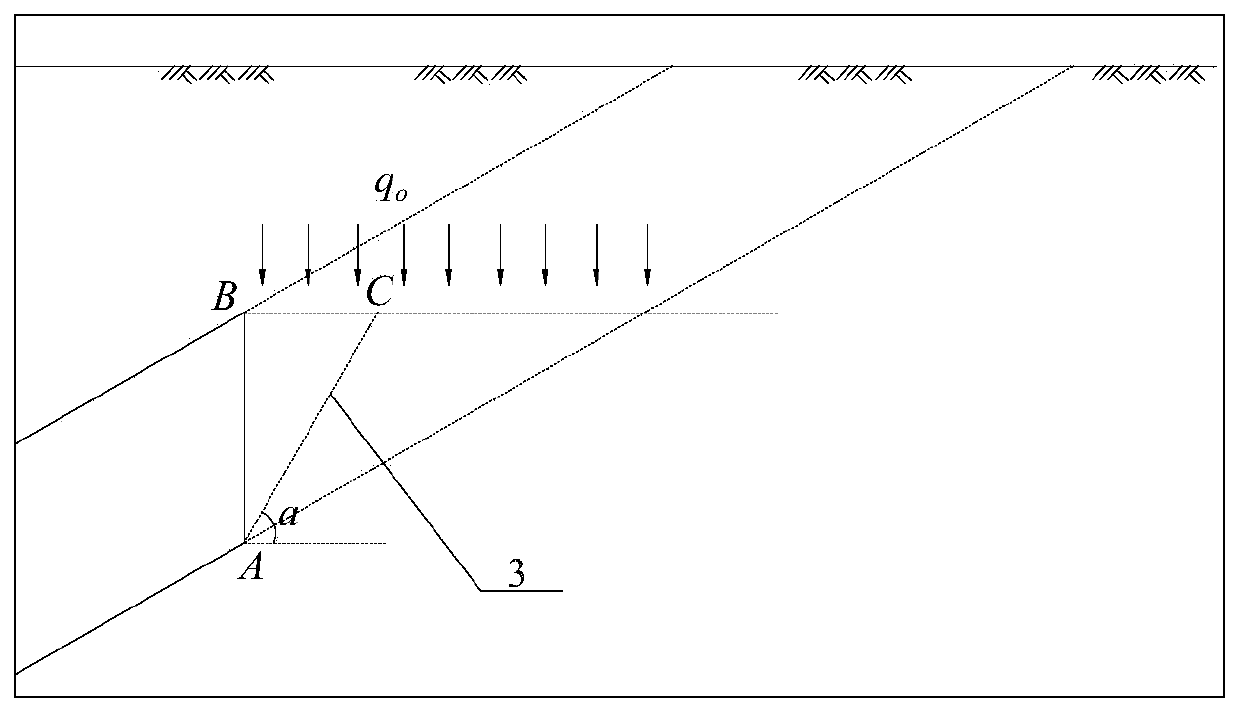

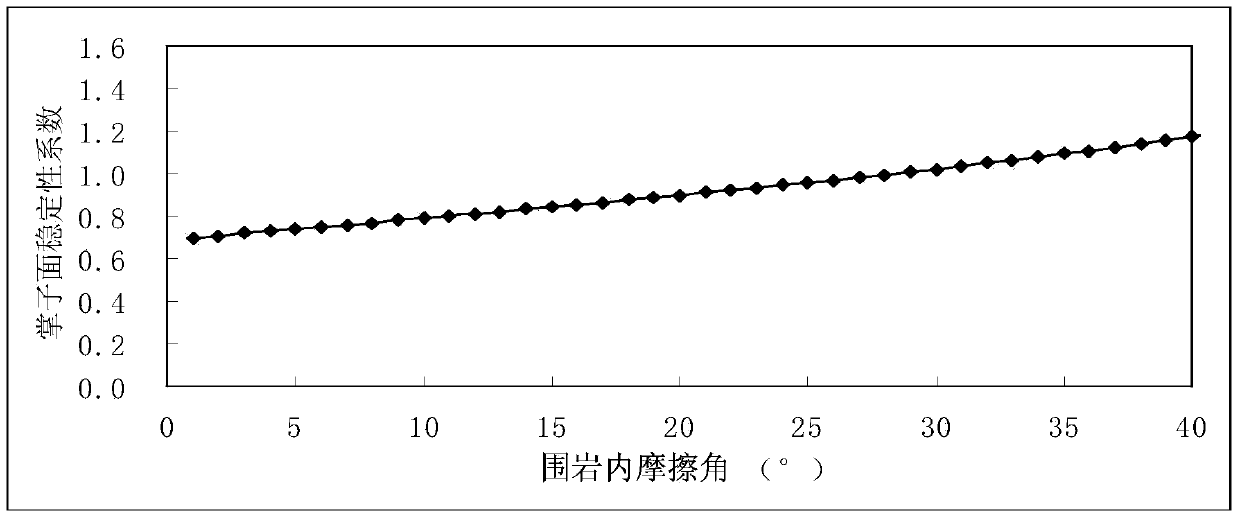

Fore support and excavating method of inclined tunnel

ActiveCN103742158AImprove securityGuaranteed stabilityUnderground chambersTunnel liningStability coefficientGrout

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD +1

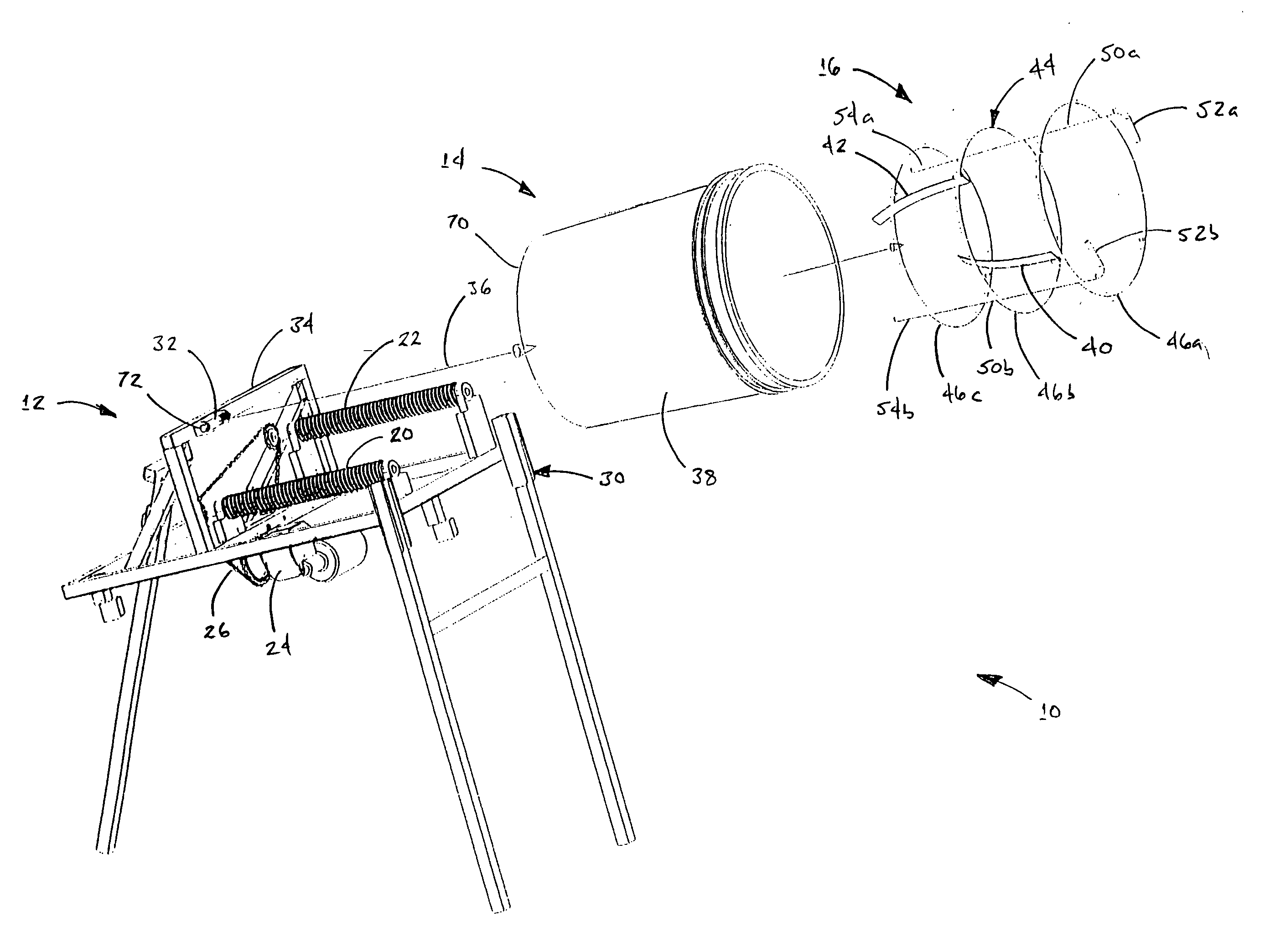

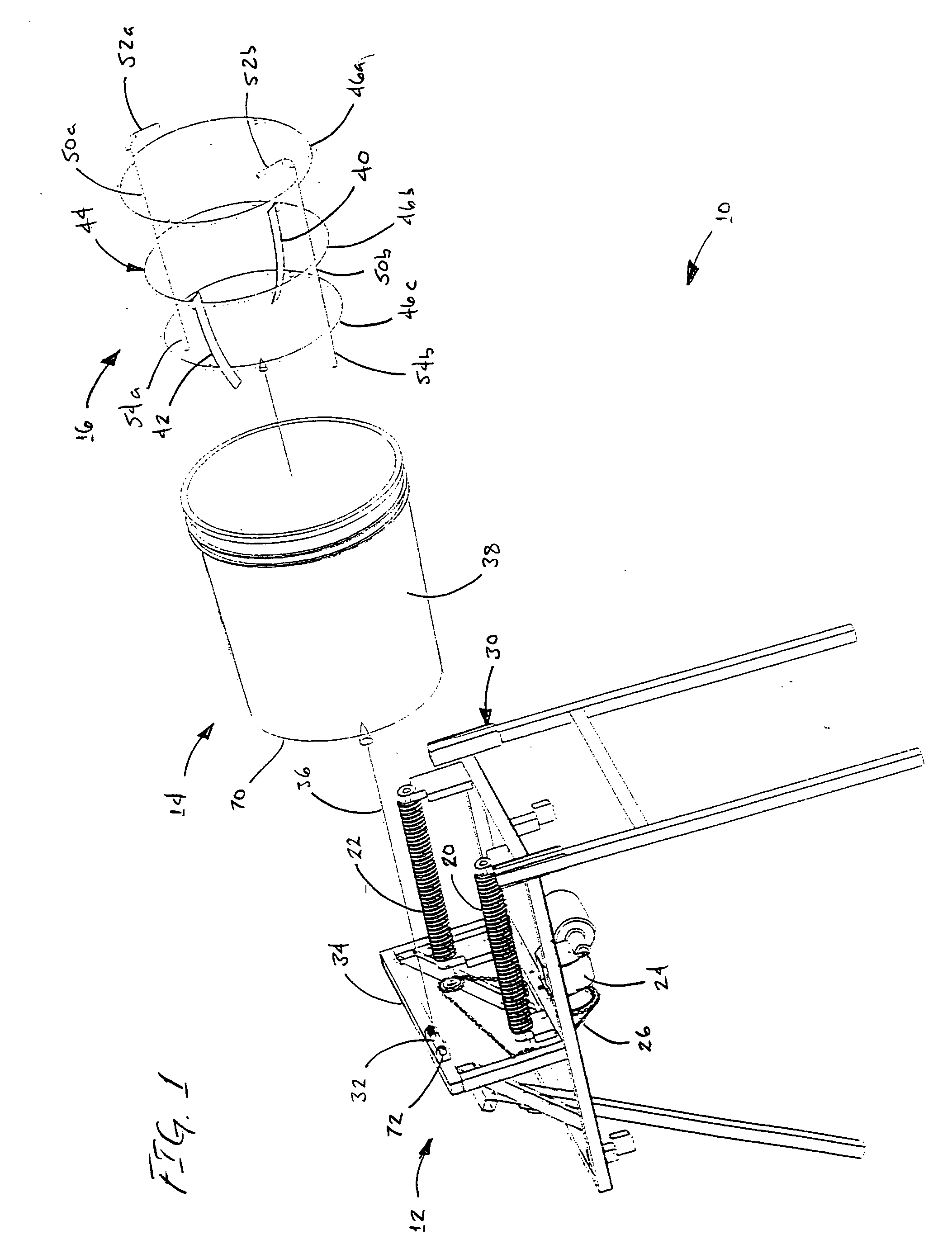

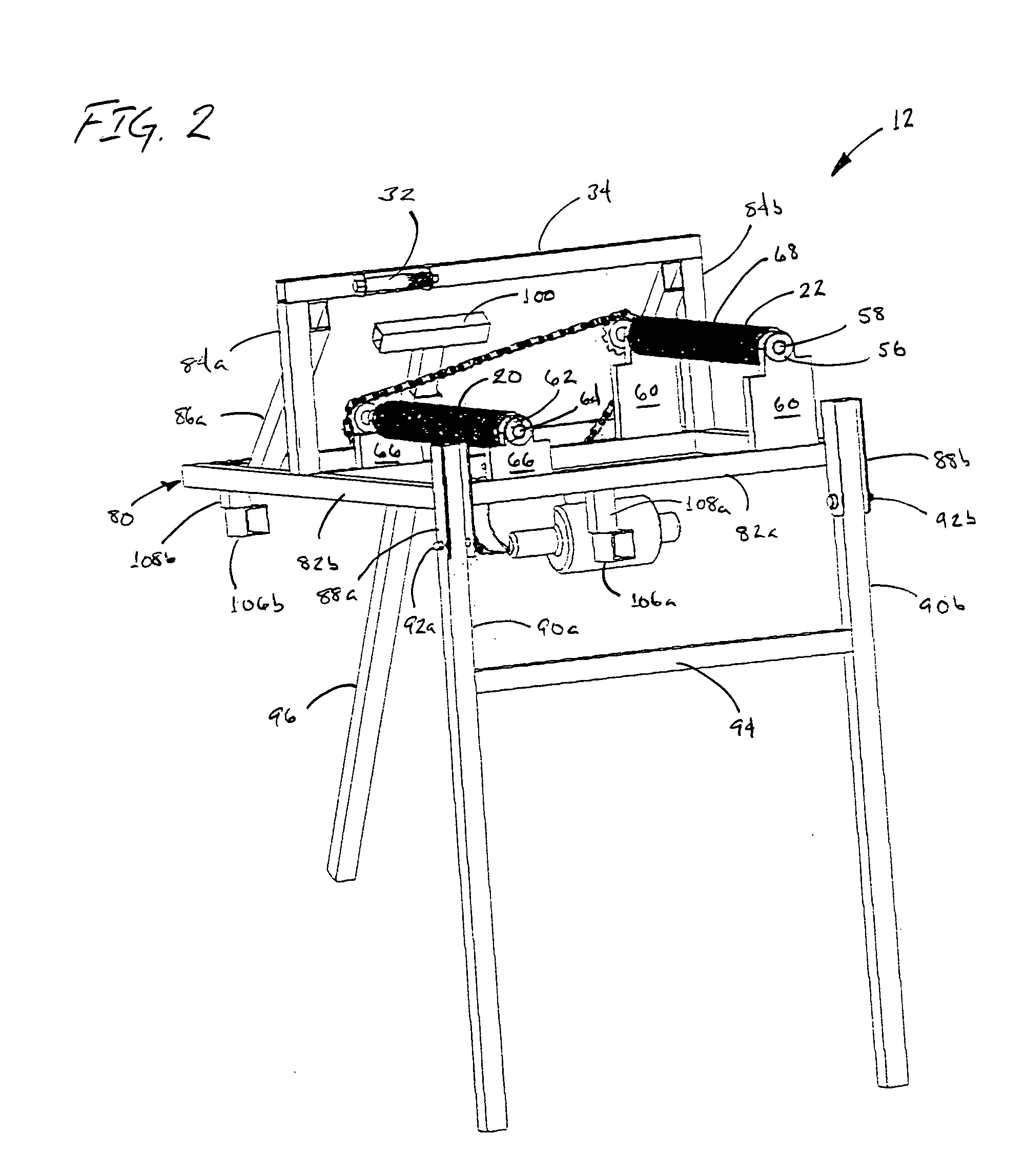

Portable mixing apparatus

InactiveUS20060028913A1Easy to transportRotating receptacle mixersTransportation and packagingMotor driveSlope angle

Owner:HASKELL GEORGE L

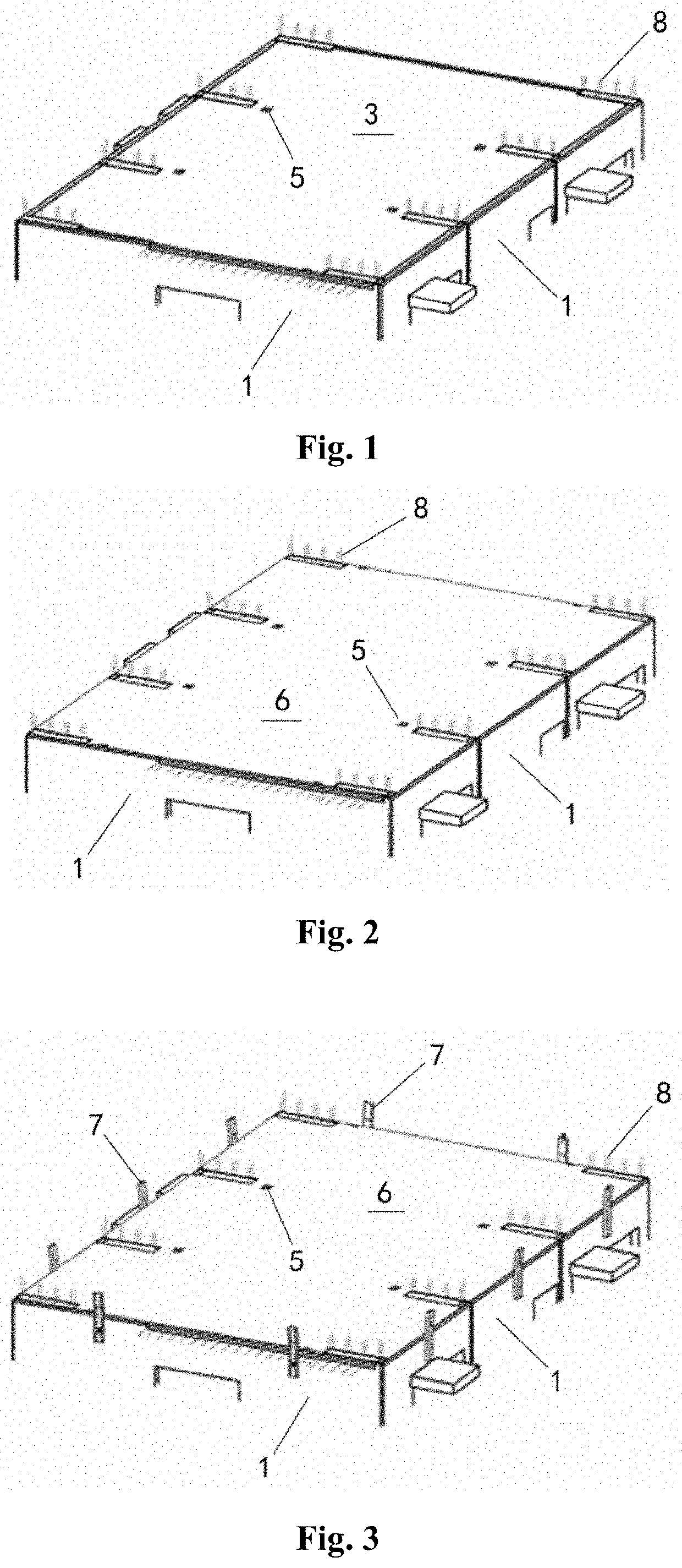

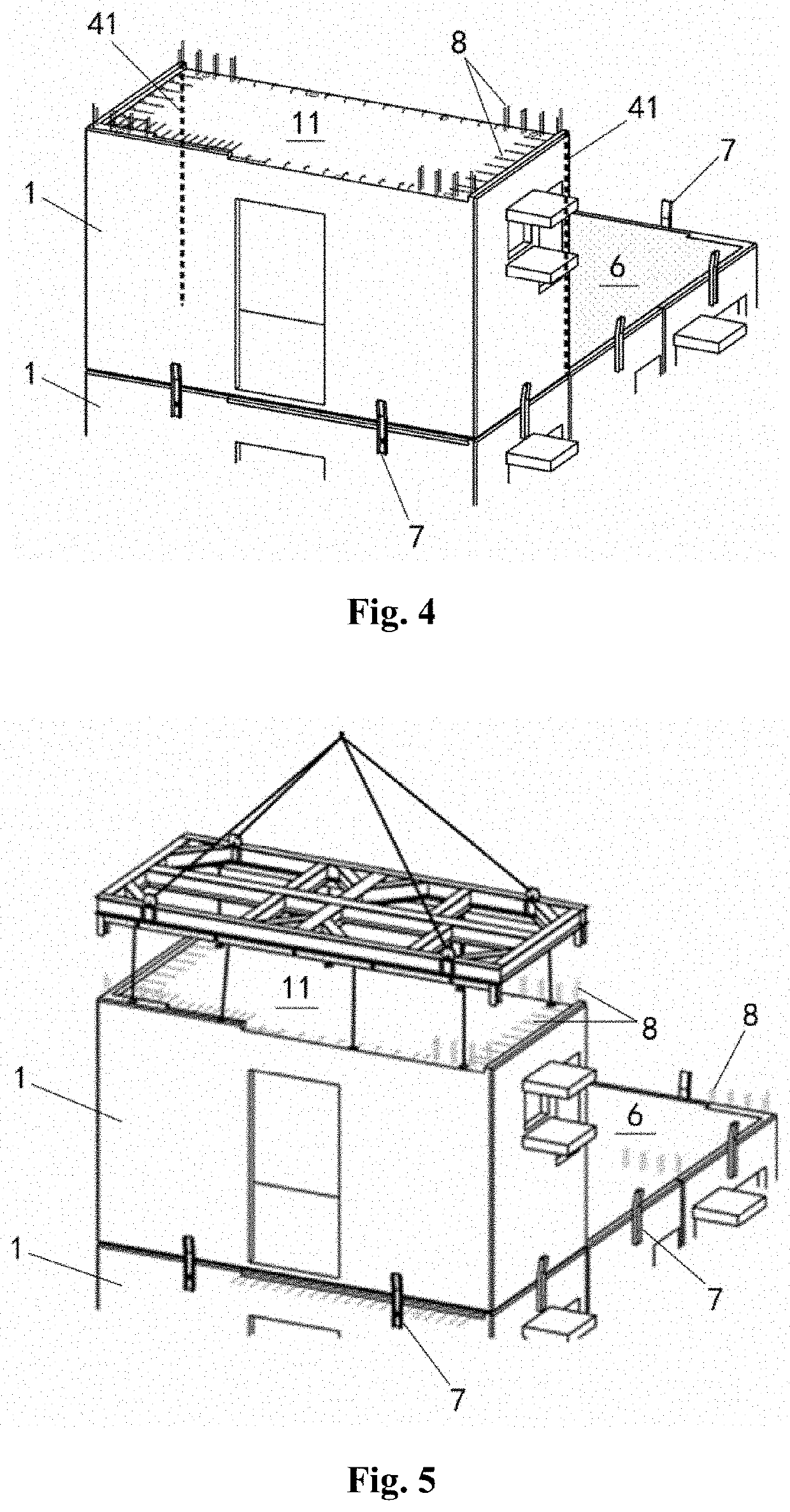

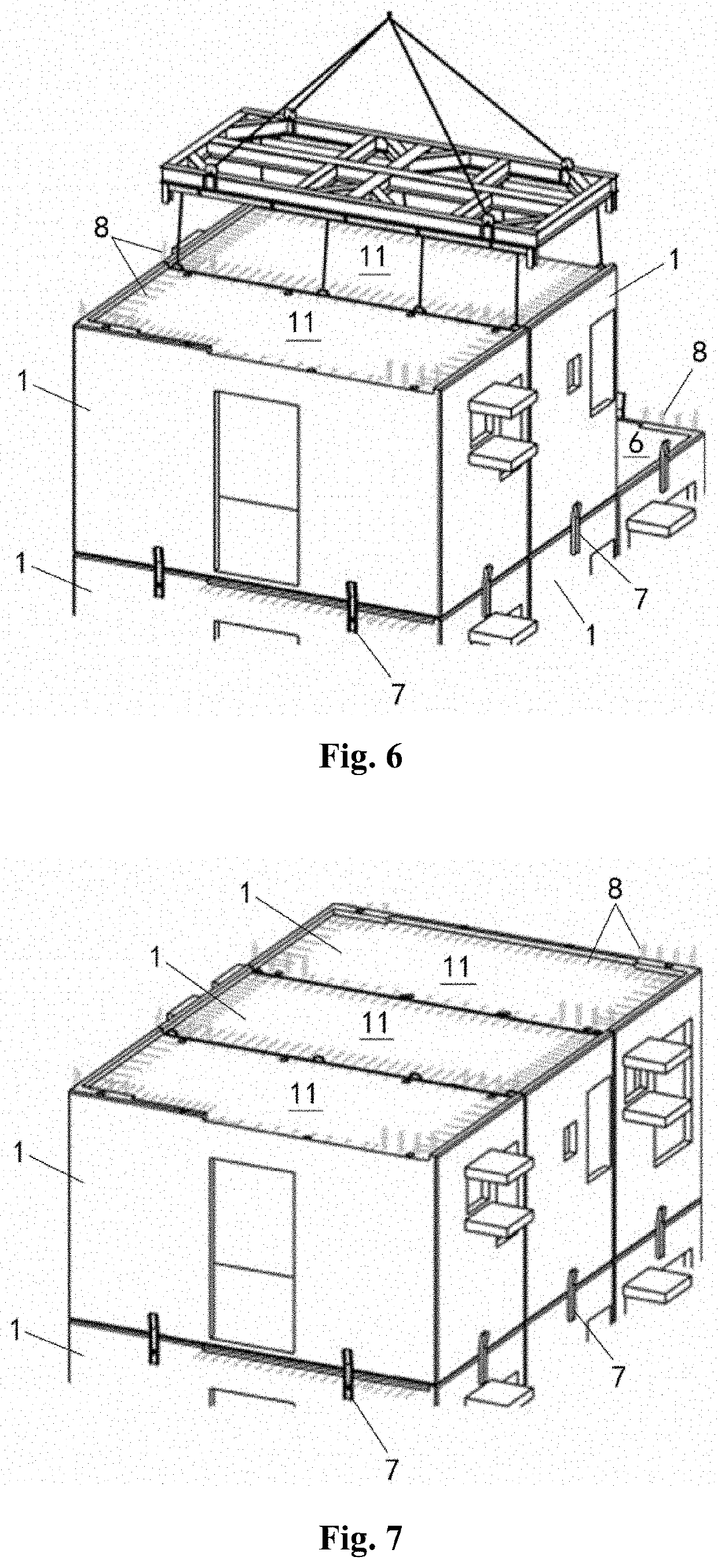

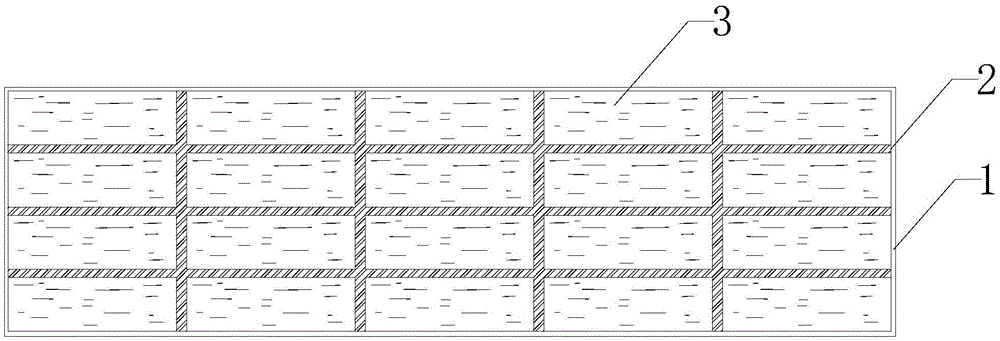

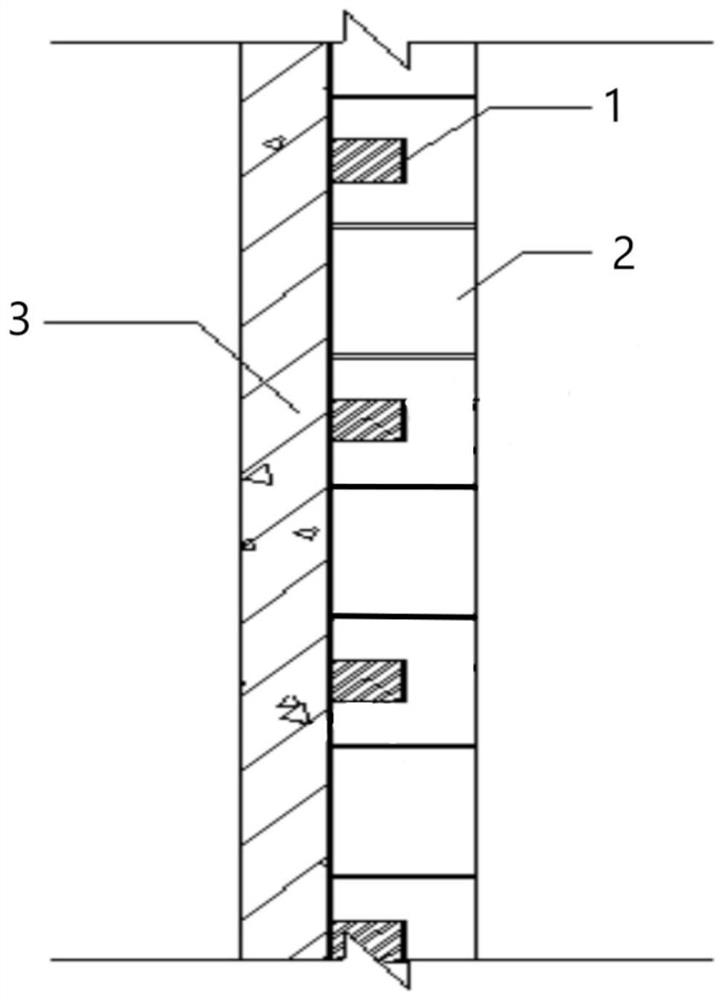

Modular Integrated Building and Construction Method Thereof

ActiveUS20200011076A1Construction is convenient and rapidShorten the overall cycleSpecial buildingBuilding constructionsArchitectural engineeringModularity

Owner:YAU LEE WAH CONCRETE PRECAST PROD SHENZHEN CO LTD

Method for grouting and wall protection of a soft stratum pile foundation through steel casing

Owner:THE 5TH CONSTR COMPANY LTD OF CHINA RAILWAY 15TH BUREAU GRP +1

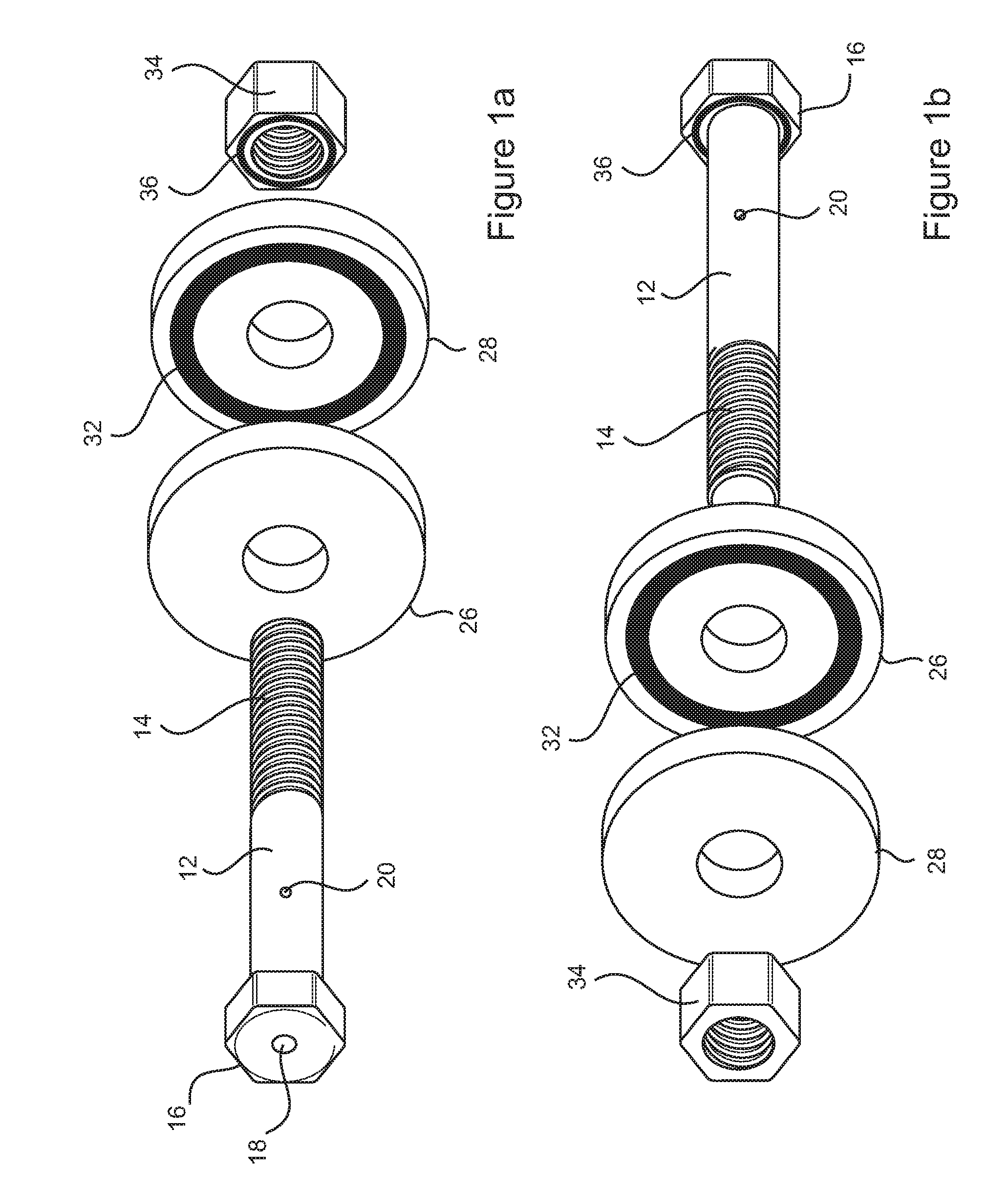

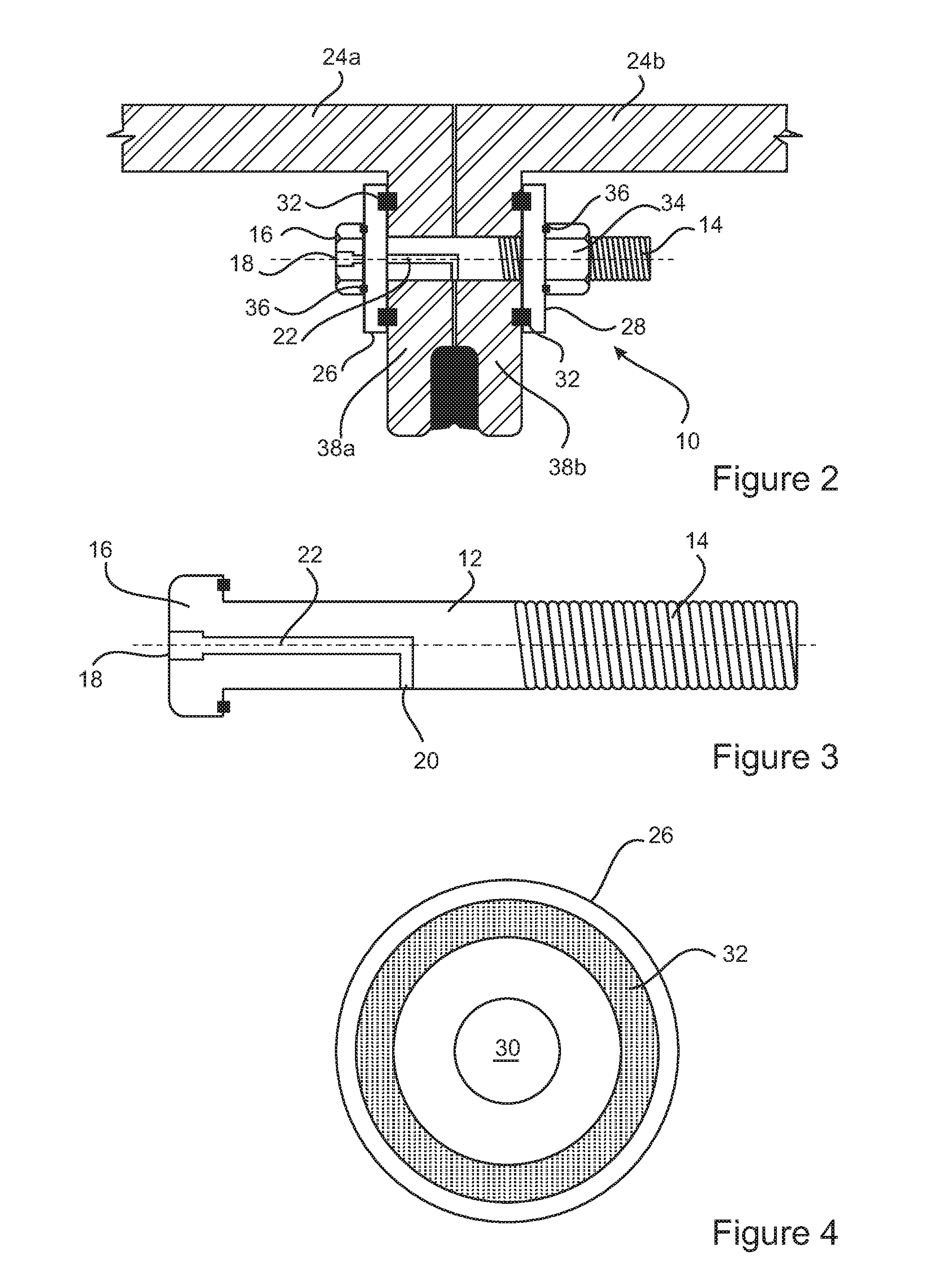

Fastener and method of sealing passage

Owner:RELBORGN +1

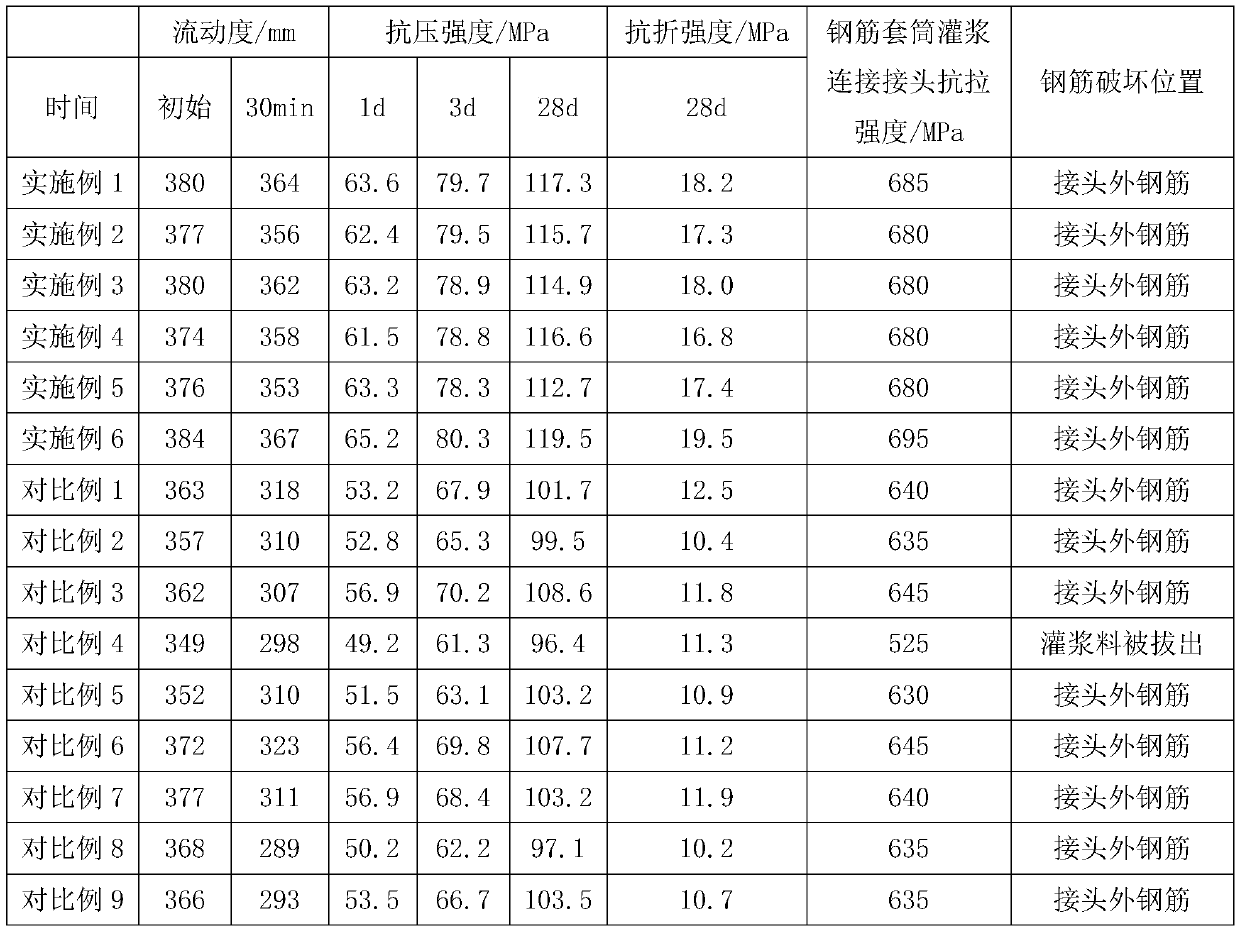

Sleeve grouting material for steel bar connection of prefabricated building

ActiveCN111517729AHigh mechanical strengthGood fluiditySolid waste managementFiberArchitectural engineering

Owner:SHENYANG JIANZHU UNIVERSITY

Sleeve valve pipe for reinforcing pit bottom of water-rich pebble bed deep foundation pit and construction process

Owner:CHONGQING UNIV OF EDUCATION

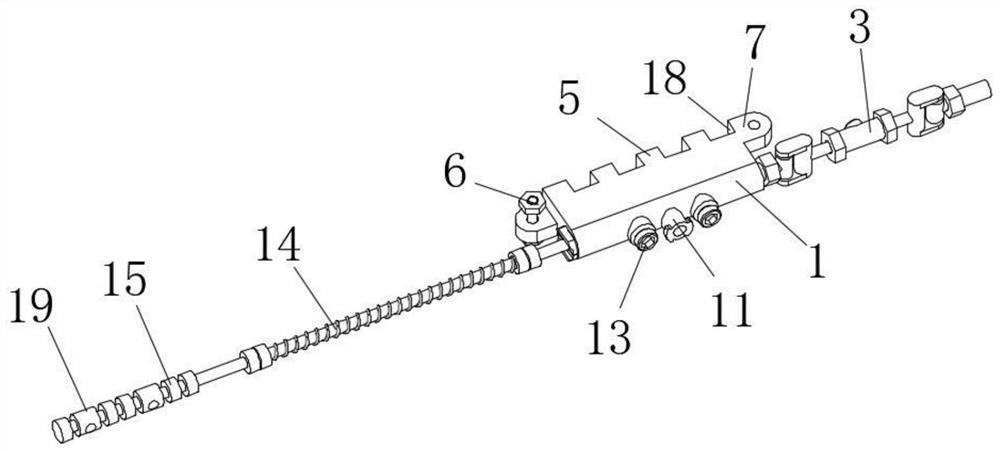

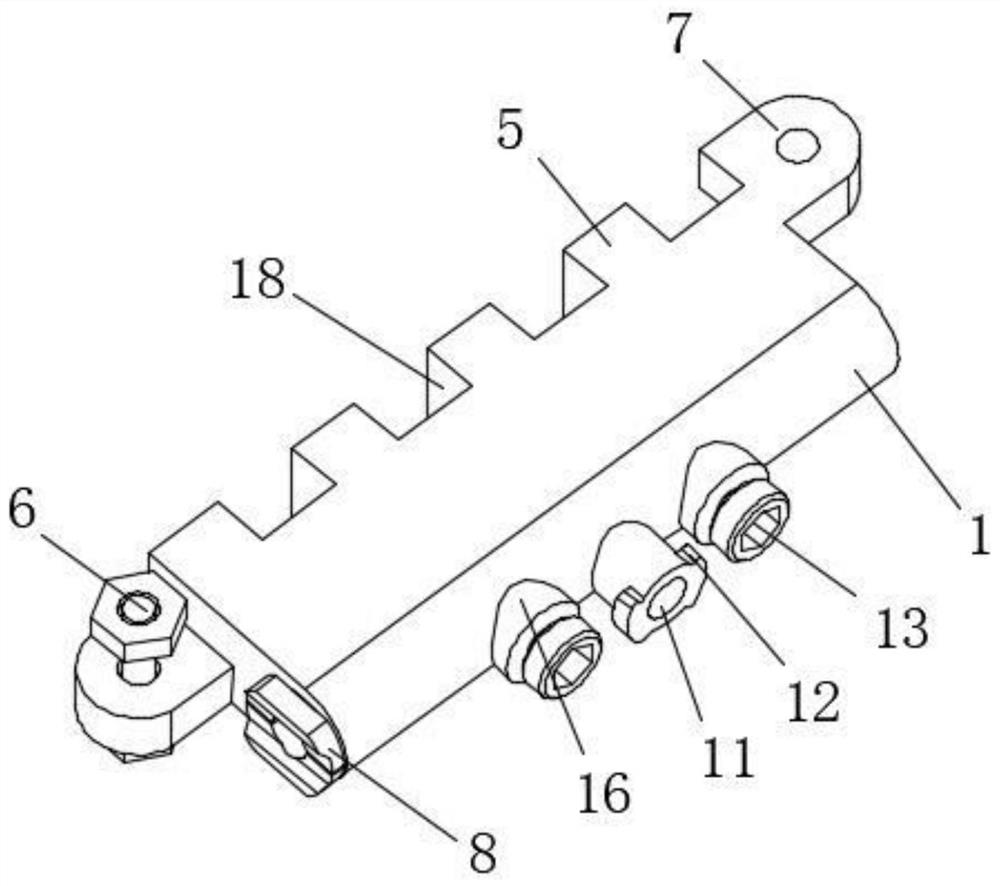

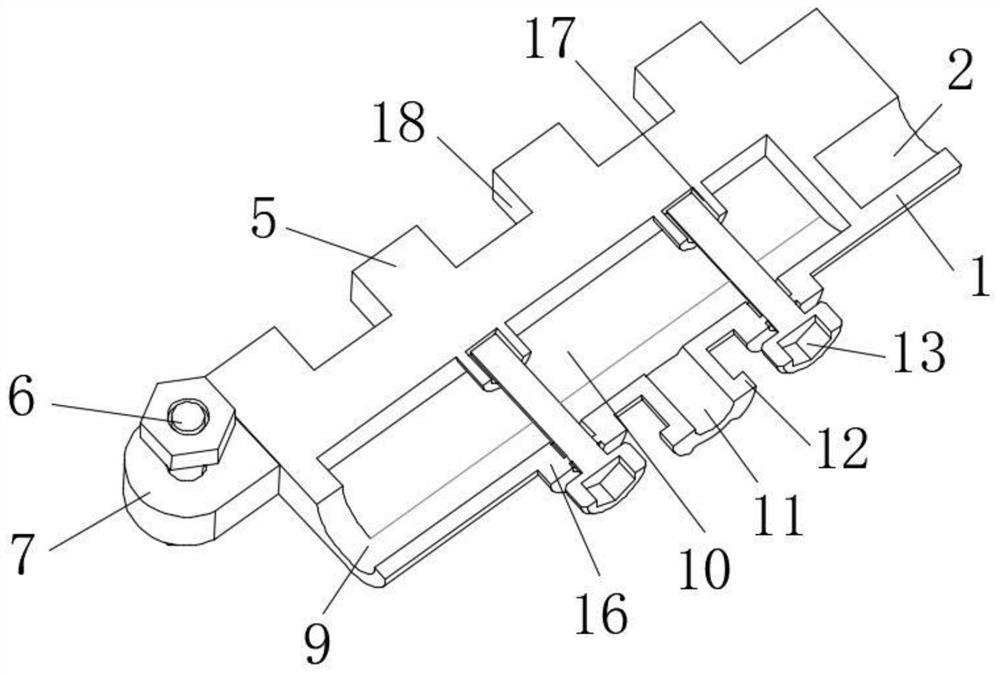

Assembly type indoor sound insulation wall auxiliary assembly

InactiveCN113818593AFast top surface tight fitEasy to fixWallsSound proofingRatchetClassical mechanics

The invention provides an assembly type indoor sound insulation wall auxiliary assembly, and relates to the technical field of sound insulation wall bodies. A linkage part is mounted on the frame part; a tightening device is slidably connected to the frame part, and a fitting part is rotatably connected to the tightening device; an edge sealing device is fixedly connected into the frame part; two floating driving parts are mounted in the frame part; two linkage expansion parts are mounted in the frame part; a ratchet-shaped tooth block is fixedly connected into the frame part, the frame part is provided with a linkage part in a matched mode; fitting driving on the top surface of a building and tight fitting between walls can be achieved; the structure is simple; the linkage is efficient; the wall installation is more stable; meanwhile, glue pollution is effectively reduced; and the sound insulation effect is effectively improved. The problems that the sound insulation performance of a building is affected, the environmental protection performance is poor and the installation is not stable enough since joints between walls are large and later grouting and glue supplementing are needed are solved.

Owner:CHANGCHUN HENGFA REAL ESTATE DEV CO LTD

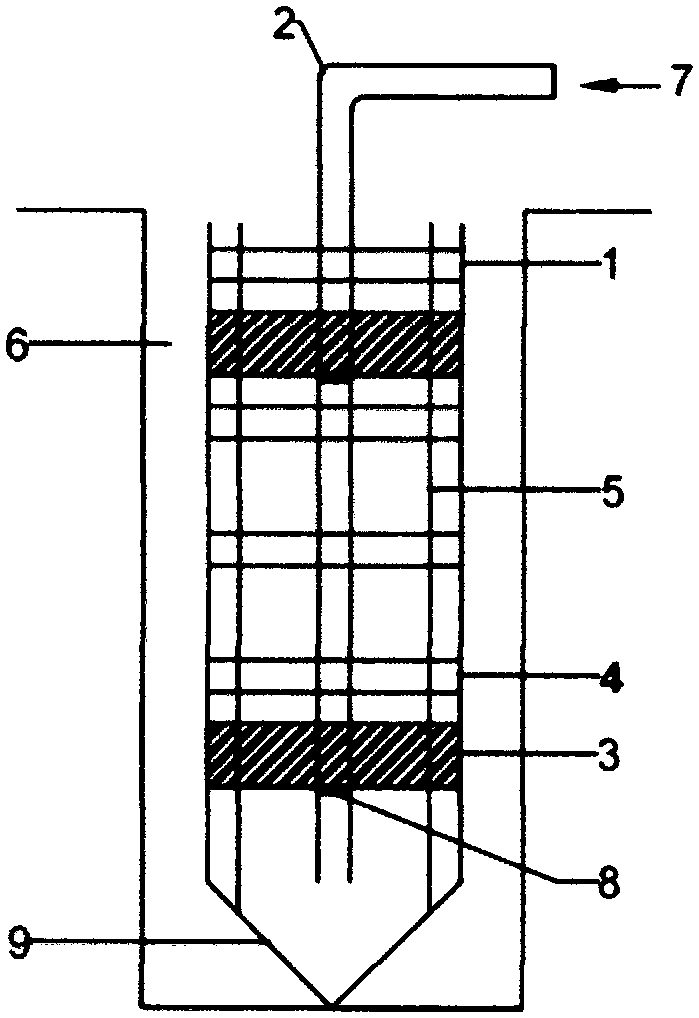

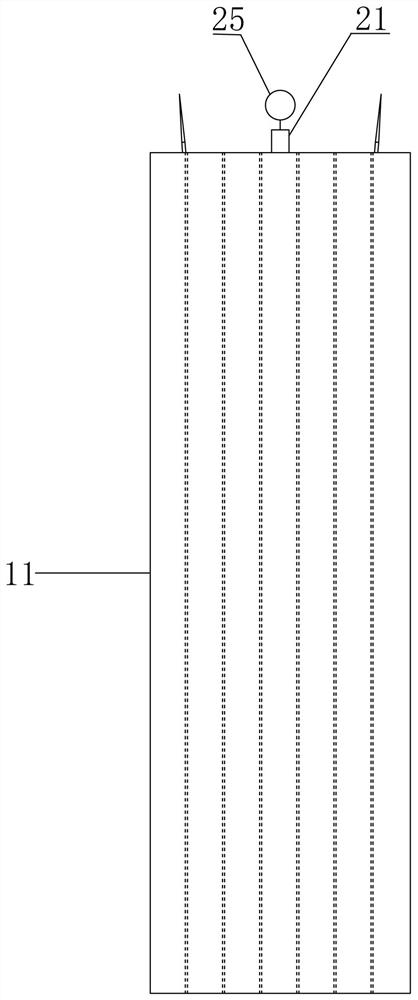

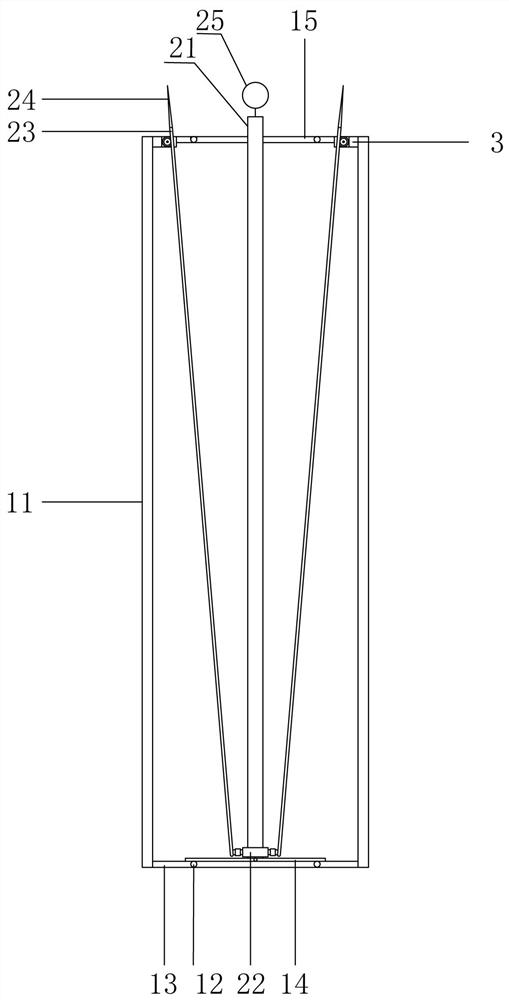

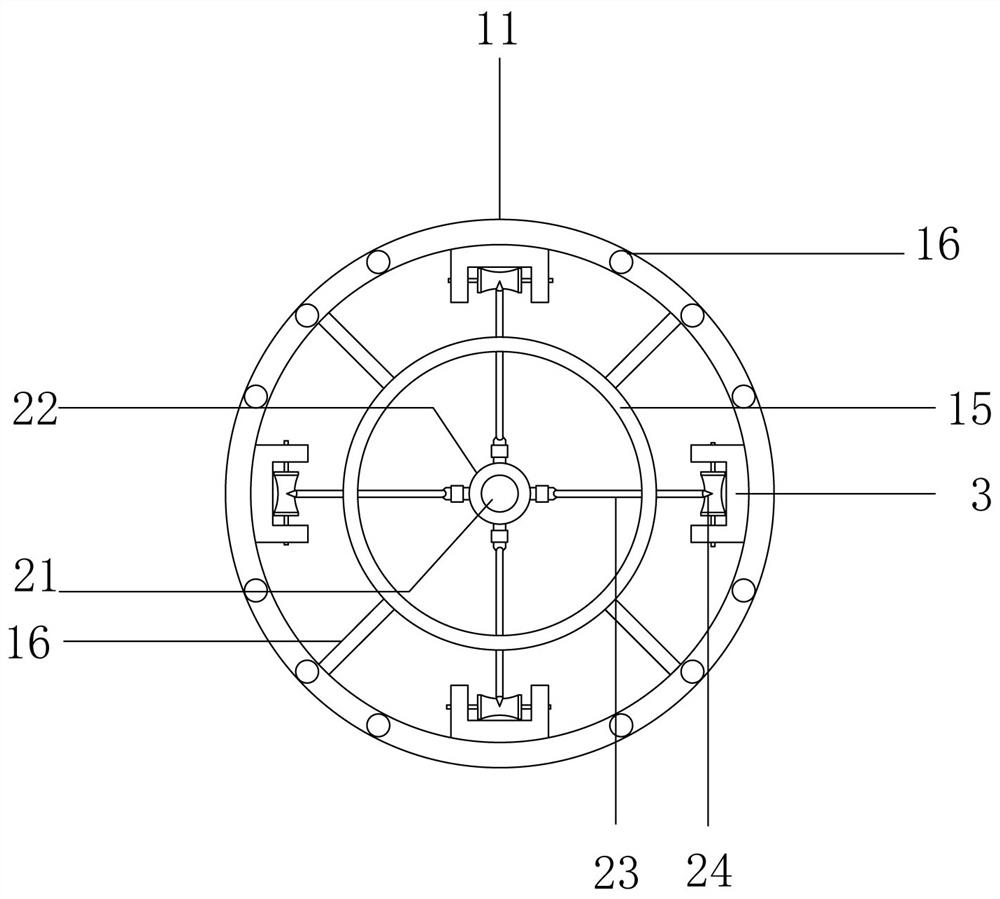

Full grout sleeve for building steel bar connecting

Owner:恒荣建设集团有限公司

Reinforcing device and method for rock slope containing weak interlayer

ActiveCN113756336AAvoid Shear Failure SituationsHigh strengthExcavationsBulkheads/pilesVertical planeUltimate tensile strength

Owner:ANSTEEL GRP MINING CO LTD

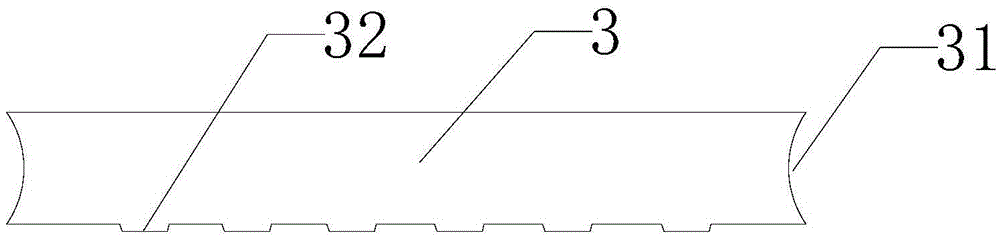

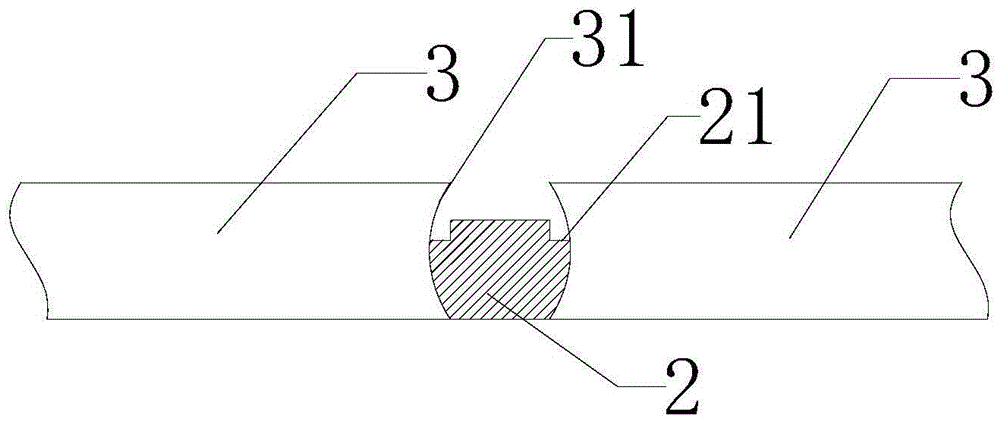

Production method for flexible tile module and prefabricated members

Owner:CHINA MINSHENG ZHUYOU

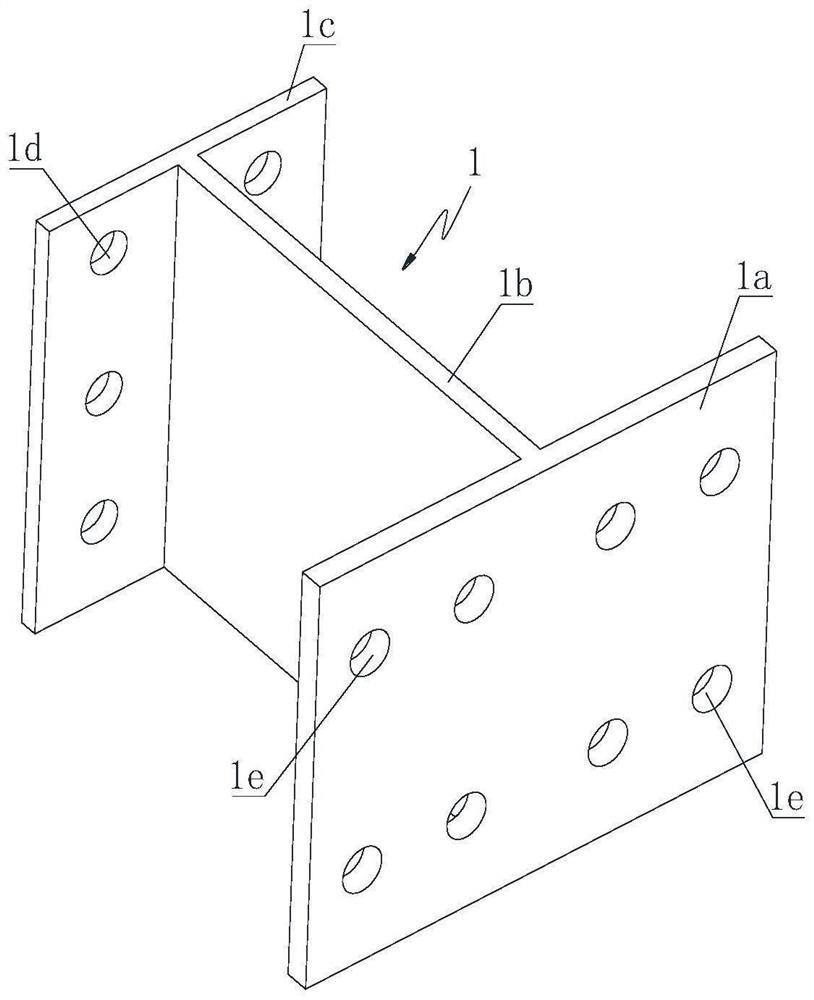

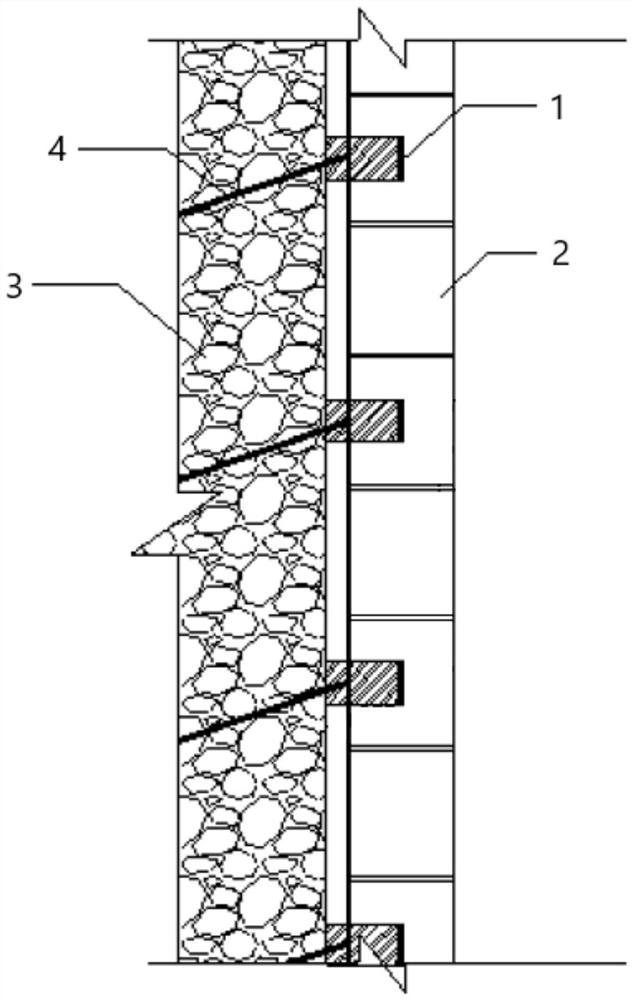

Construction method of T-shaped steel plate tie city wall

PendingCN114776132AImprove structural stabilityImprove the overall quality and safety factorFencingBuilding repairsSteel platesGrout

The invention discloses a T-shaped steel plate tie city wall construction method which comprises the following steps that firstly, a T-shaped tie steel plate is manufactured, and the T-shaped tie steel plate comprises a web plate and a wing plate perpendicularly connected to one end of the web plate; secondly, cutting grooves matched with the wing plates are formed in the ends of the stone in a cutting mode; thirdly, the ends, away from the wing plates, of the web plates are fixedly connected to the inner side wall; and fourthly, stone is piled on the outer side of the inner side wall, the cutting groove of the stone is fixed to the wing plate of the T-shaped tie steel plate, and then the gap between the cutting groove of the stone and the T-shaped tie steel plate is filled with concrete mortar or grouting materials. The stone building wall has the beneficial effects that the stone is grooved and buckled with the T-shaped tying steel plate on the inner side wall body, then concrete is filled, the outer stone building wall body and the inner side wall body can be tied into an integral structure, and the stone building wall has the technical advantages that the stone building wall is good in structural stability and high in quality safety coefficient.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

High-bearing-capacity pavement structure and paving construction method

PendingCN114575212AGuaranteed filling densityAchieving uniformity of distributionPaving reinforcementsIn situ pavingsScreedCrushed stone

The high-bearing-capacity pavement structure comprises a graded broken stone layer, a mortar layer is laid on the graded broken stone layer, a bonding layer is laid on the mortar layer, and an asphalt concrete overlay layer is laid on the bonding layer; a reinforcement cage is arranged in the bonding layer, outer ribs are arranged on the upper side and the lower side of the reinforcement cage, and the outer ribs extend into the mortar layer and the asphalt concrete overlay layer. The paving construction method of the high-bearing-capacity pavement structure comprises the following steps: 1) leveling a site and erecting a template; (2) paving a large-particle-size gravel layer; (3) paving a small-particle-size gravel layer; (4) rolling to form a graded broken stone layer; the construction method comprises the following steps of (1) paving cement mortar to form a gravel grouting layer, (2) mounting a reinforcement cage, (3) paving a bonding layer, (4) paving a bonding layer, and (5) paving cement mortar to form a gravel grouting layer, (6) mounting a reinforcement cage, (7) paving a mortar layer, (8) paving a bonding layer, and (9) paving an asphalt concrete overlay layer.By adopting the structure and the method, the pavement structure is optimized, the stability between layers of pavements is enhanced, the slippage risk of the pavement is reduced, and reliable environmental conditions are provided for normal operation of roads.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD

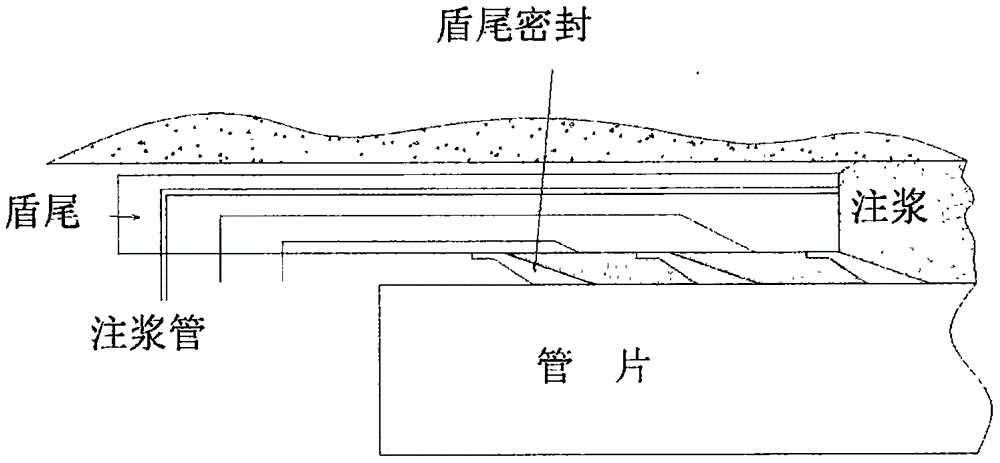

Additive for decreasing shrinkage rate of synchronous grouting materials

InactiveCN106437729ALow shrinkageEasy to shrinkTunnelsShrinkage rateAlum

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

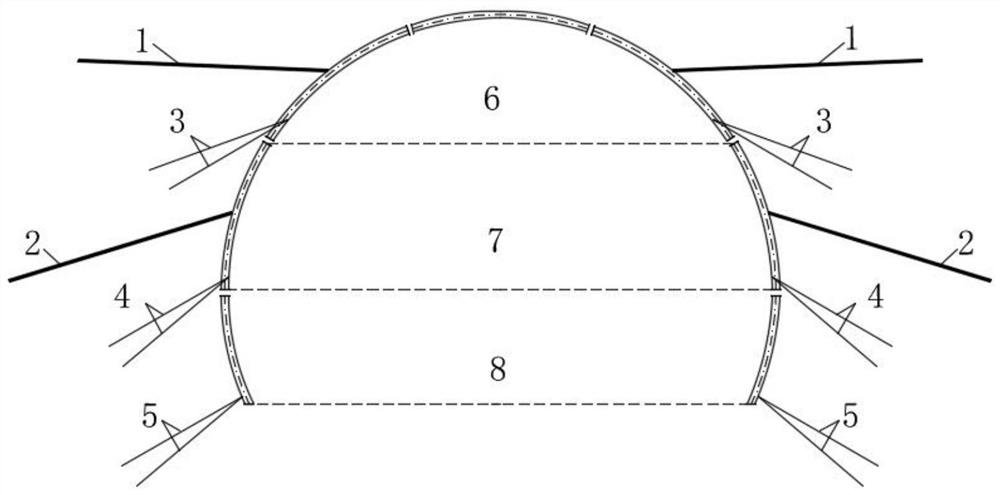

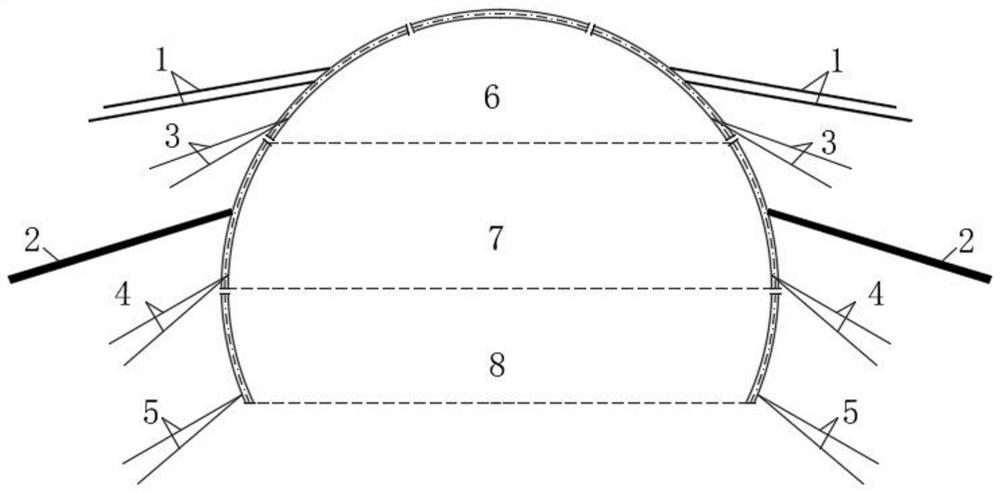

Method for improving stability of primary support structure in soft rock tunnel construction

ActiveCN112523788AImprove mobilityFlexible drilling operationsHydro energy generationAnchoring boltsHand heldRock tunnel

Owner:CHANGAN UNIV +1

Preparation method of prefabricated concrete member

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

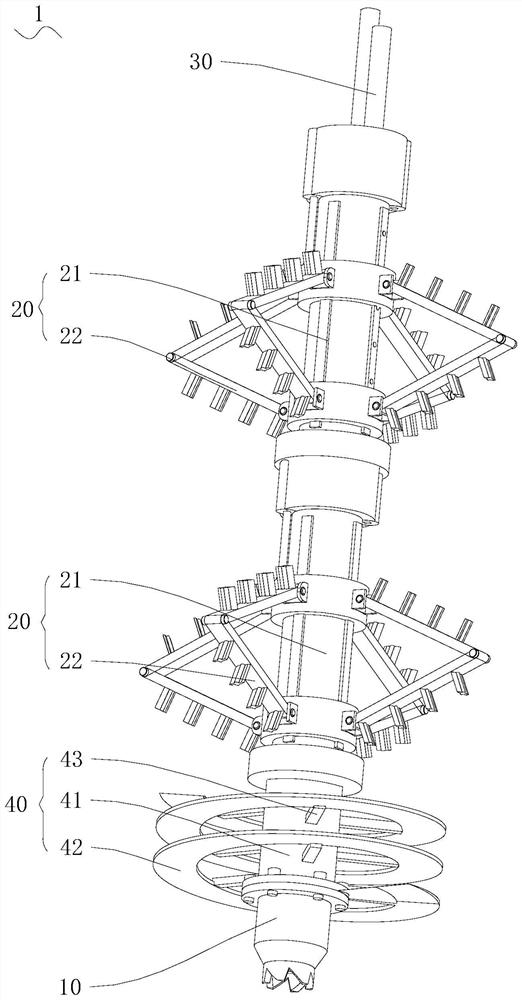

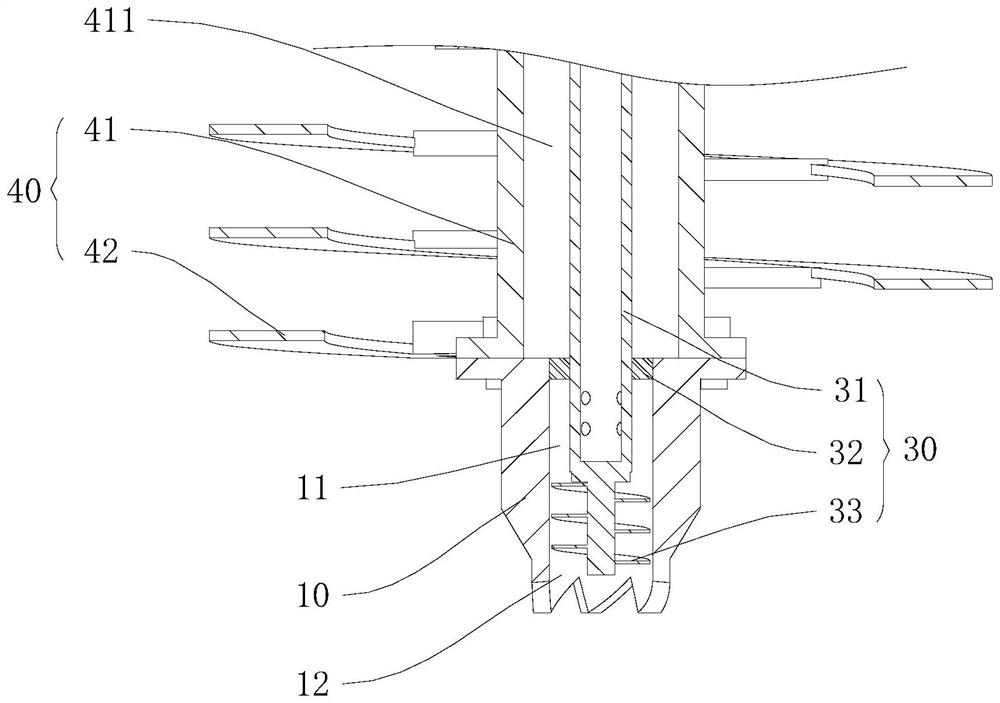

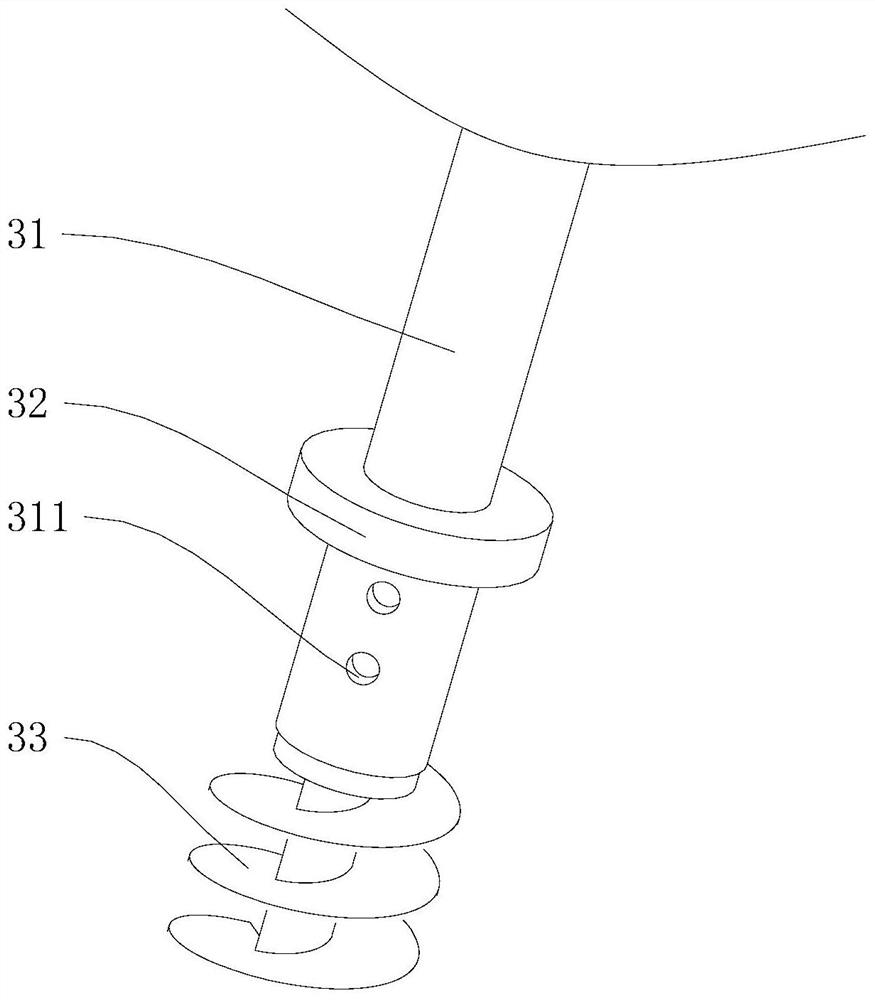

Bidirectional stirring device and composite foundation construction method

Owner:SHANDONG LUQIAO CONSTR +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap