Additive for decreasing shrinkage rate of synchronous grouting materials

A technology of simultaneous grouting and shrinkage rate, applied in mining equipment, tunnels, earthwork drilling, etc., can solve the problems of weakened control ability of formation subsidence and obvious surface subsidence, so as to improve the shrinkage problem and reduce the shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In a broad embodiment of the present invention: the present invention provides a kind of additive that reduces the shrinkage rate of synchronous grouting material, and the additive that described reduction synchronous grouting material shrinkage comprises: industrial alum and industrial gypsum, described synchronous grouting material reduction The amount of additives for shrinkage rate is 5kg / m 3 .

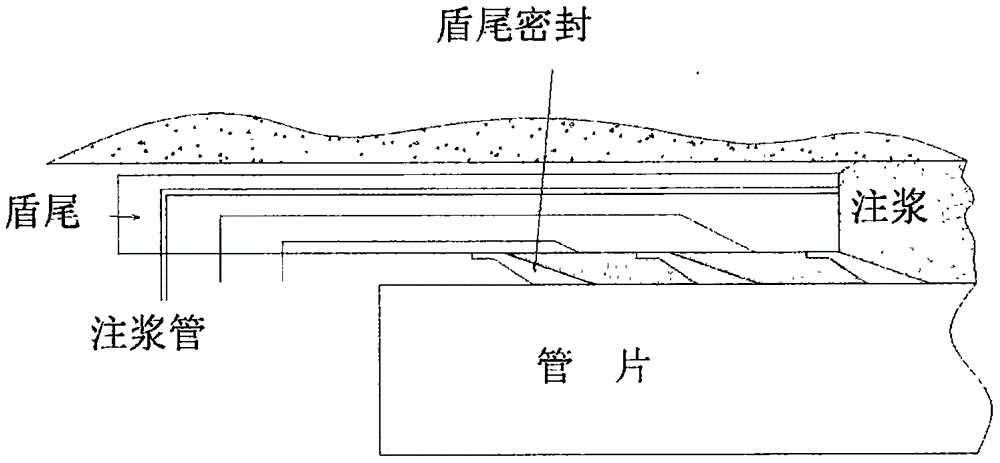

[0014] Such as figure 1 As shown, the synchronous grouting is shield tail grouting, that is, while the shield is advancing, there is a large shield tail gap at the shield tail after a few rings of the tunnel face, where the shield tail is about to leave the segment, so it is necessary to inject The slurry ensures the stability of the formation.

[0015] In actual construction, if the synchronous grouting slurry shrinks greatly, it may cause the land subsidence to exceed the requirements in some risk source areas, so it is necessary to reduce the shrinkage of the grout.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap