Method for improving stability of primary support structure in soft rock tunnel construction

A technology for structural stability and tunnel construction, which is applied in earth-moving drilling, mining equipment, installation of anchor rods, etc. Anchoring effect, strong drilling rig mobility, and the effect of improving grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content, technical solutions and features of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

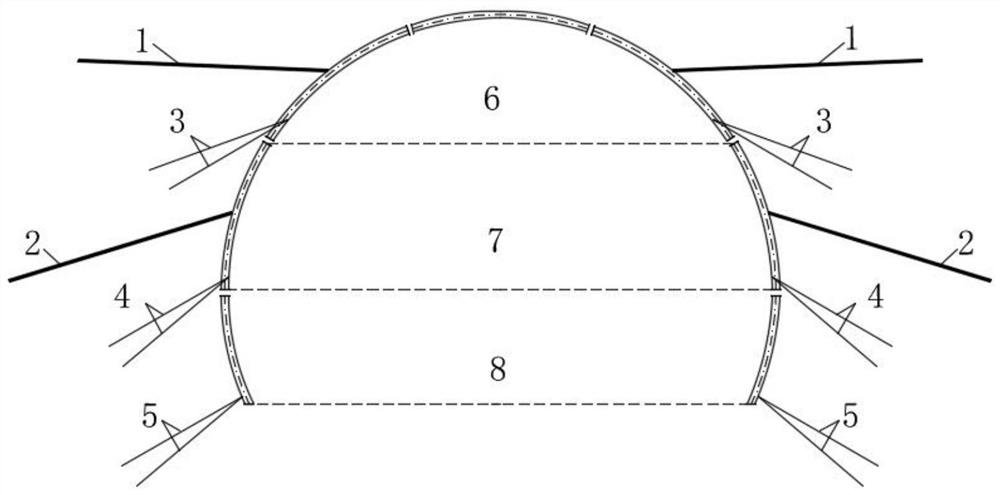

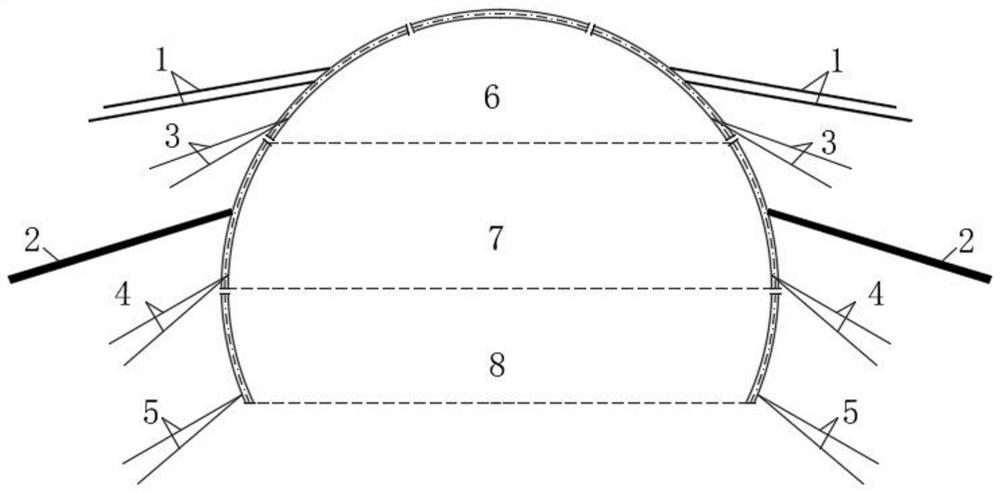

[0022] The present invention proposes a method for improving the stability of the initial support structure in the construction of the tunnel step method for the three-step construction method, such as figure 2 As shown, the constrained anchor rod 1 of the upper step is located at the arch waist of the upper step, and two are installed between the two adjacent steel frames on the left and right sides of the upper step, a total of four; according to the grouting and pulling test results of the constrained anchor rod , the drawing force of a 6m long φ42 steel pipe is 267kN, and the drawing force of a 6m long φ76 steel pipe is 530-540kN. Obviously, the drawing force of two 6m long φ42 steel pipes is the same as that of a 6m long φ76 steel pipe. equal strength

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap