Lateral-moving and rotating carrier and three-dimensional garage

The technology of a three-dimensional garage and a carrier is applied to the buildings, building types, buildings, etc. where cars are parked, and can solve the problems of the inability to realize the underground arrangement of the comb-tooth lifting structure, the limitation of the use space of the three-dimensional garage, and the restriction of the development direction of the three-dimensional garage. To achieve the effect of diversifying the way of accessing the car, using it flexibly and conveniently, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

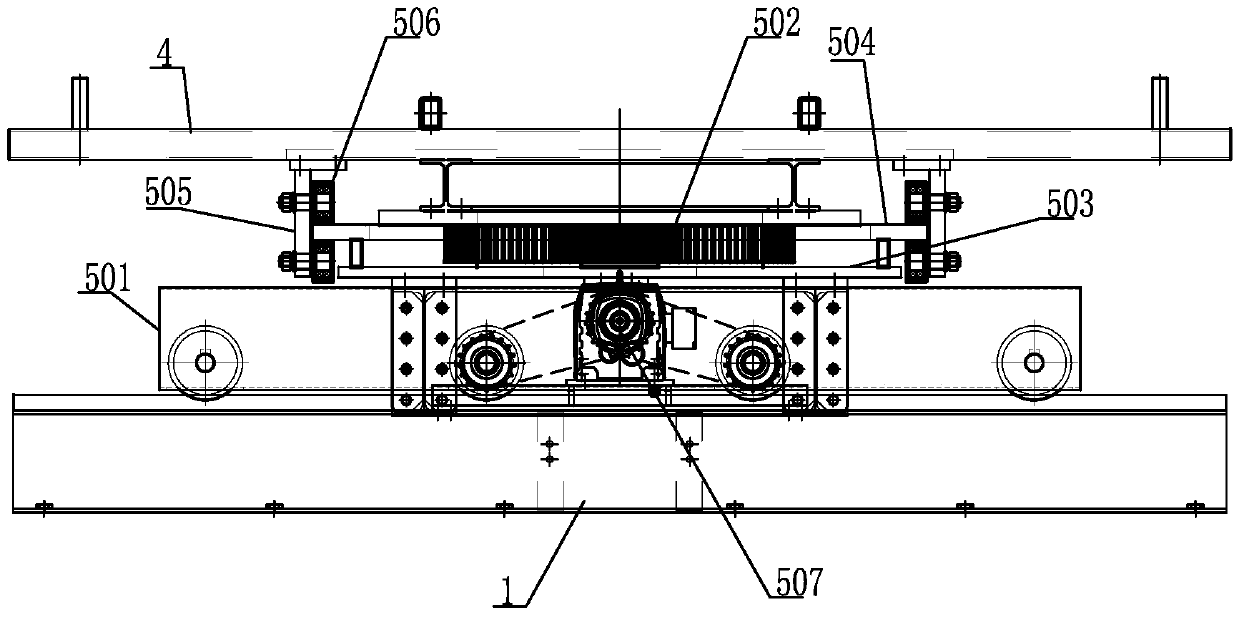

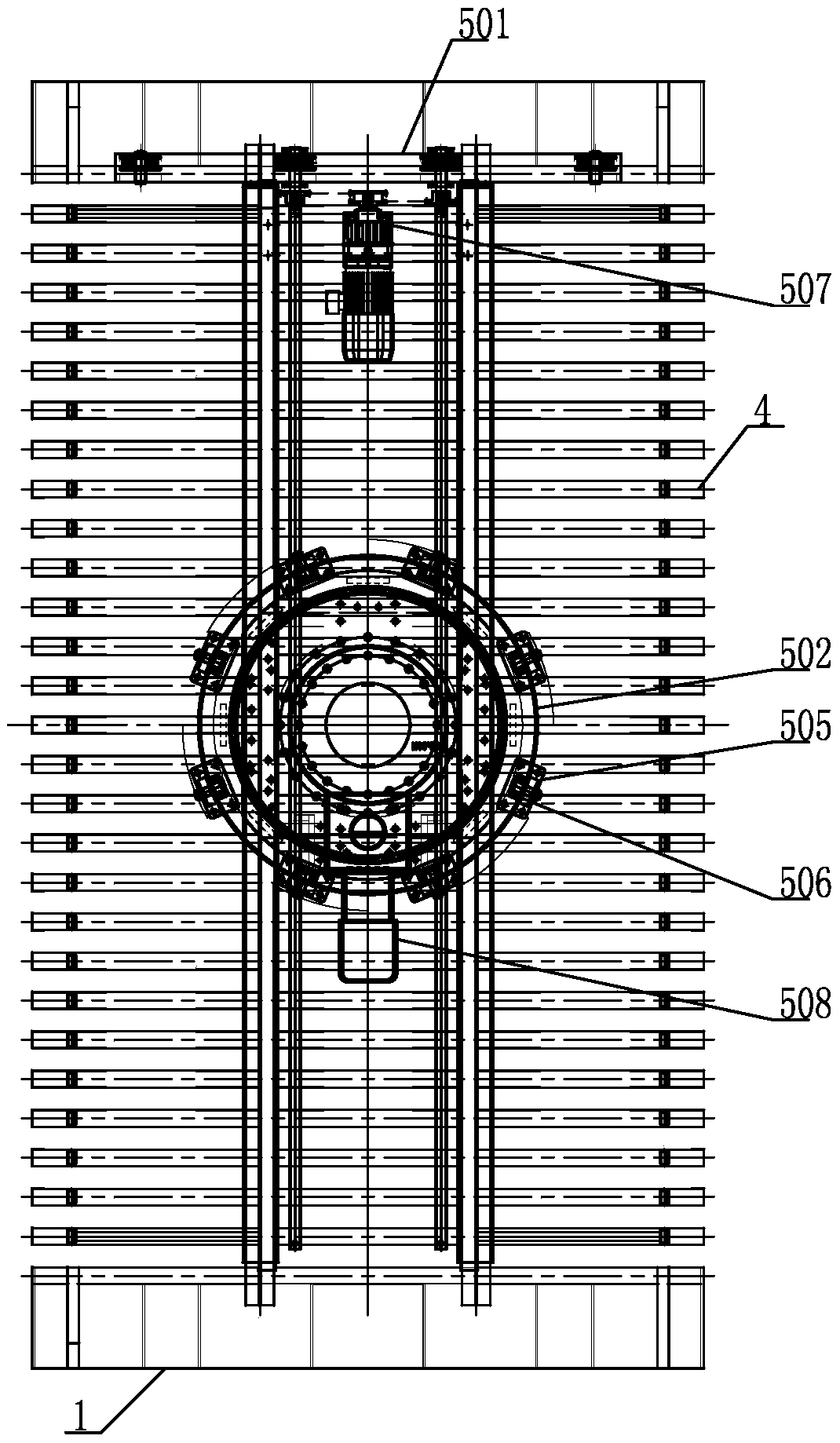

[0040] Such as figure 1 and figure 2 Commonly shown, the present invention provides a traverse rotary carrier, including a traverse frame 501 driven by a first power device 507 and laterally slidably mounted on the slide rail 8, the first power device 507 is preferably driven by an electric motor Sprocket chain transmission mechanism, a base 503 is fixedly installed on the traversing frame 501, and a rotary disk 502 driven by a second power device 508 is installed on the base 503. The second power device 508 is preferably an electric motor or a hydraulic motor. The drive gear is fixed on the power output shaft of the device 508, and the ring gear meshing with the driving gear is fixed on the outer surface of the rotary disc 502. The rotation of the rotary disc 502 is realized through gear transmission, and the rotary disc 502 is fixedly equipped with an exchange comb. frame 4, while the traversing frame 501 moves laterally, the rotary disc 502 realizes the rotation under the ef

Embodiment 2

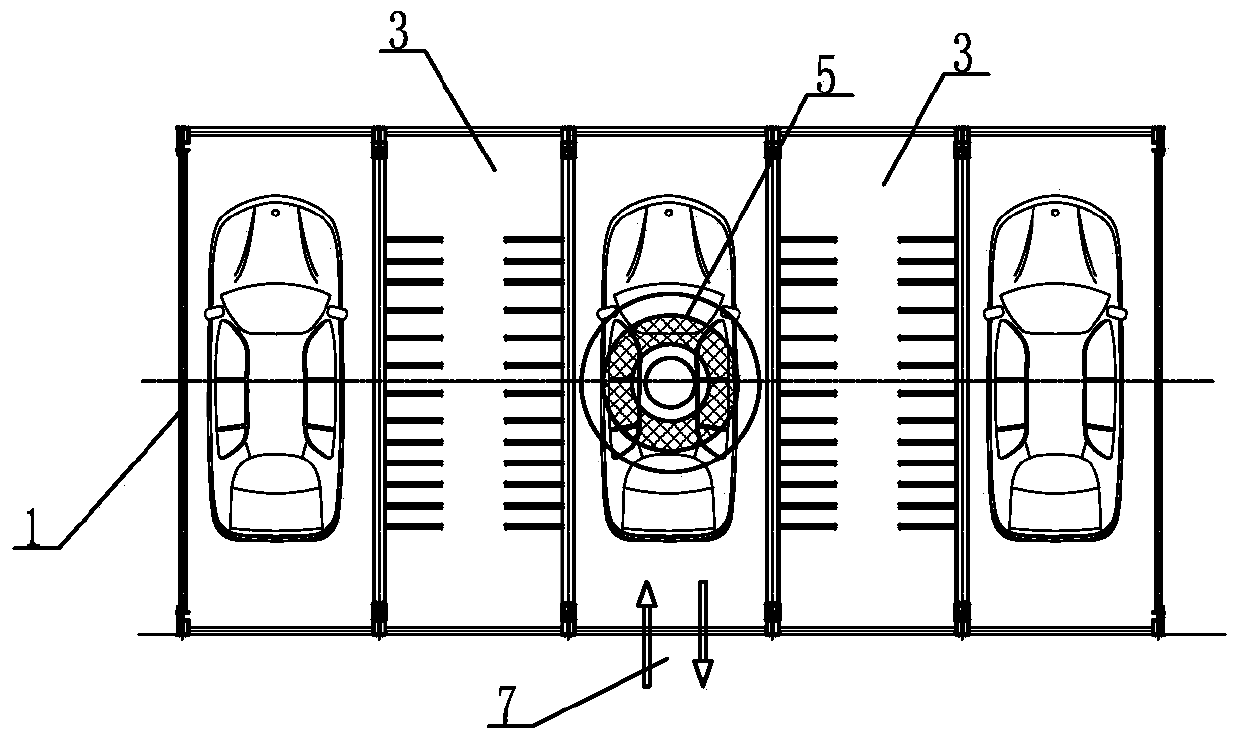

[0045] Such as Figure 3 to Figure 7b Commonly shown, the present invention also discloses a three-dimensional garage, including the lateral movement and rotary carrier 5 described in Embodiment 1. The present invention makes improvements based on the traditional comb-toothed three-dimensional garage, and does not change its working Therefore, the traditional way of accessing the car has not changed, so I won't repeat it here. The traverse rotary carrier 5 is laterally moved and installed in the conveyance channel 2 in the steel structure frame 1 , and the slide rail 8 extends laterally in the conveyance channel 2 .

[0046] The vehicle entrance and exit 7 is located in any parking space of the transport passage 2, and the vehicle entrance and exit direction is perpendicular to the moving direction of the laterally moving rotary carrier 5. Such as image 3 As shown, when the traversing rotary carrier 5 is located in the middle of the two lifting channels 3, the vehicle entrance

Embodiment 3

[0052] The present invention also discloses a three-dimensional garage, the structure of which is basically the same as that of Embodiment 2, the difference being that the vehicle entrance and exit 7 is located at the leftmost or / and rightmost parking space of the transport passage 2, that is to say, the vehicle entrance and exit 7 It can be set at the leftmost parking space of the transportation passage 2, or it can be arranged at the rightmost parking space, and the vehicle entrance and exit 7 can also be set at the leftmost and rightmost parking spaces of the transportation passage 2 at the same time, and the vehicle entry and exit direction is consistent with the transverse direction. The direction of movement of the rotary carrier 5 is consistent, such as Figure 8 As shown, the side entry and exit vehicles are realized, so that the storage distance of the comb-tooth exchange three-dimensional garage is no longer limited by the radius of the lane. For example, if the plane

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap