Roll-free variable-stiffness vibration damping bearing

A technology of variable stiffness and support strength, applied to climate change adaptation, roads, tracks, etc., can solve the problems of unsatisfactory vibration and noise reduction, poor elastic performance, and high price, so as to avoid direct erosion, low cost, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

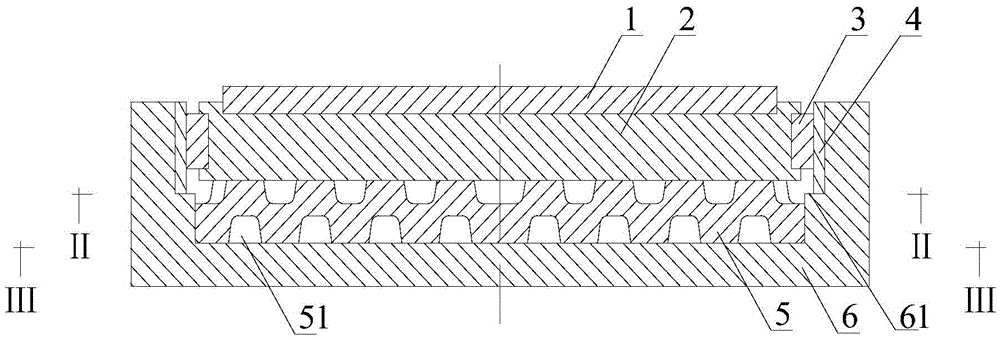

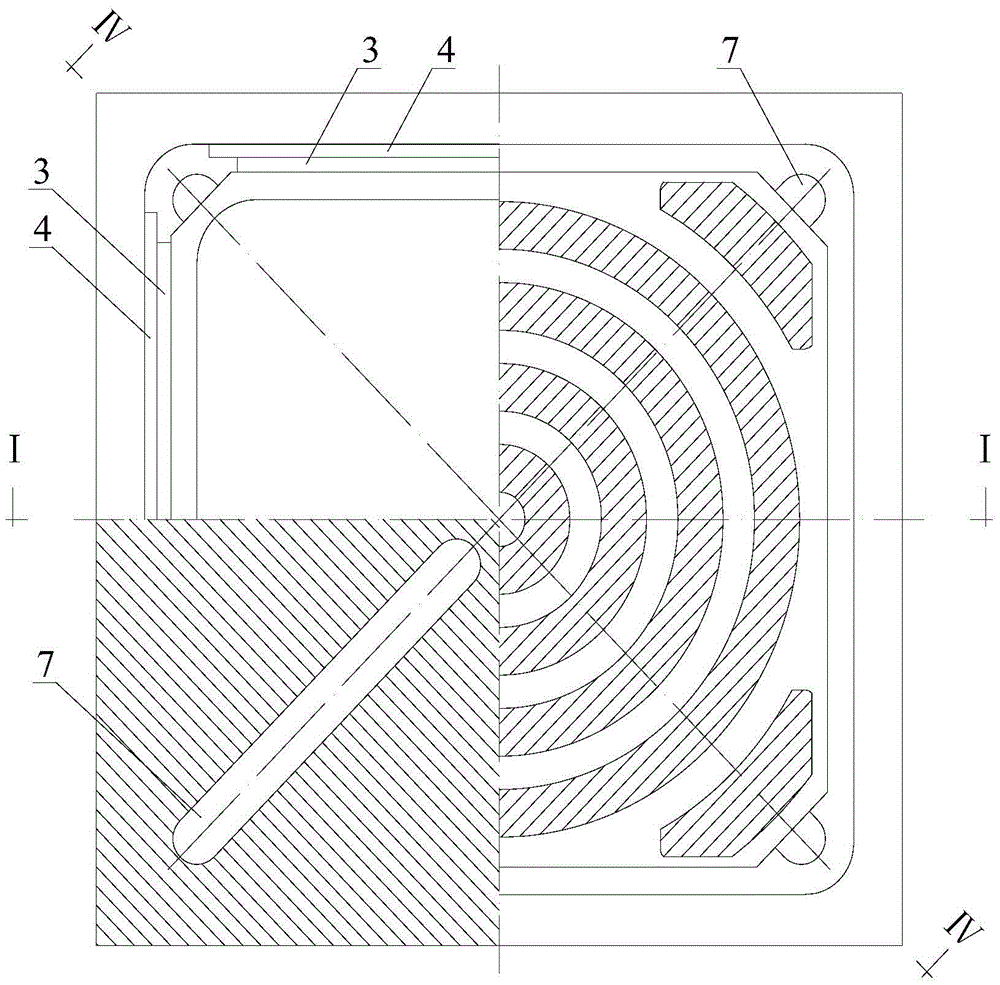

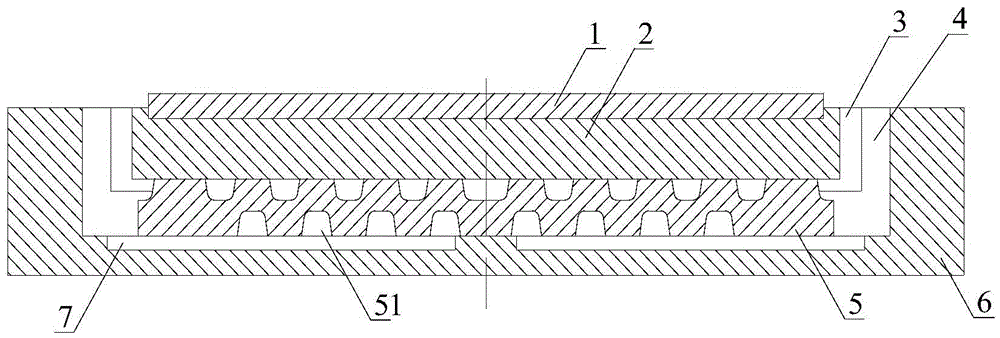

[0022] Please refer to Figure 1 to Figure 5 As shown, the non-rolling variable stiffness damping support of the present invention includes: a bottom basin 6 having an upwardly facing opening, and a rectangular or cylindrical accommodating space inside the accommodating space The rubber plate body 5, the lining plate body 2, the backing plate body 1, the stainless steel plate body 4, and the anti-friction guide plate body 3 are sequentially housed from bottom to top. The rubber plate body 5 is used to maintain a certain support strength and maintain a good Elastic properties. The damping support structure of the present invention has simple structure and low manufacturing cost.

[0023] Wherein, the lower surface of the lining board body 2 is in contact and connection with the upper surface of the rubber board body 5, and the upper surface of the lining board body 5 is in contact and connection with the lower surface of the backing board body 1. The rubber plate body 5 is provided

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap