Glass fixture

A glass fixture and angle technology, applied in the field of clamping tooling, can solve problems such as unfavorable enterprise product efficiency, affecting enterprise production efficiency, unreliable glass clamping, etc., to avoid glass vibration and wear, avoid deformation, and reduce hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0045] Embodiment one:

[0046] like figure 1 and figure 2 As shown, a glass fixture is characterized in that it includes an installation shaft 1 and a stop tooth, the stop tooth is fixedly arranged on the outer surface of the installation shaft 1, and the stop tooth is made of copper. The centerline of the installation shaft 1 is a straight line. The hardness of the limit teeth made of copper is lower than that of steel teeth, which can avoid glass vibration wear during cleaning. At the same time, the heat resistance of the limit teeth made of copper is stronger than that of plastic teeth, which can avoid Deformation during tempering process ensures clamping reliability.

[0047] In this embodiment, the stop teeth include two sets of first stop teeth 2 arranged symmetrically, and the included angle between the two groups of first stop teeth 2 is 180 degrees. The shape of the first limiting tooth 2 is sinusoidal.

[0048] In this embodiment, the installation shaft 1 is made

Example Embodiment

[0050] Embodiment two:

[0051] The difference between this embodiment and Embodiment 1 is:

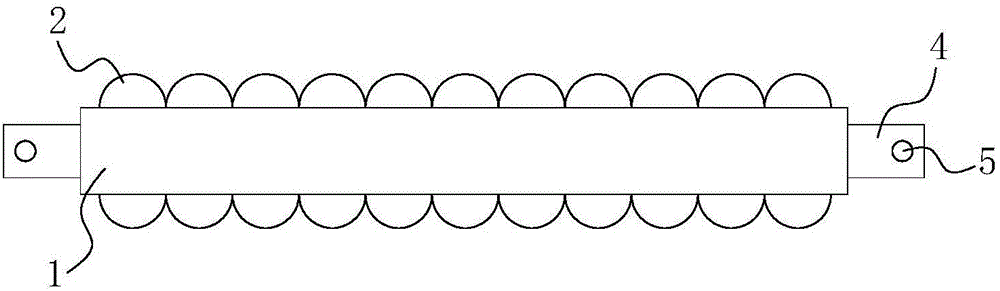

[0052] like image 3 and Figure 4 As shown, the limiting teeth include two groups of symmetrically arranged first limiting teeth 2, and the angle between the two groups of first limiting teeth 2 is 180 degrees. The first limiting tooth 2 includes several semicircular rods connected in sequence, and the opening directions of the several semicircular rods are the same. The mounting shaft 1 is made of steel.

Example Embodiment

[0053] Embodiment three:

[0054] The difference between this embodiment and Embodiment 1 is:

[0055] like Figure 5 and Image 6As shown, the limiting teeth include two groups of symmetrically arranged first limiting teeth 2, and the angle between the two groups of first limiting teeth 2 is 180 degrees. The first limiting tooth 2 includes several V-shaped rods connected in sequence, and the opening directions of the several V-shaped rods are the same. The installation shaft 1 is a cuboid, and two groups of the first limiting teeth 2 are respectively arranged on two opposite sides of the cuboid.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap