Water cutting geological rock sample machining device and method

A rock sample and processing device technology, applied in the field of geotechnical engineering science, can solve problems such as heavy machines, damage to human health, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

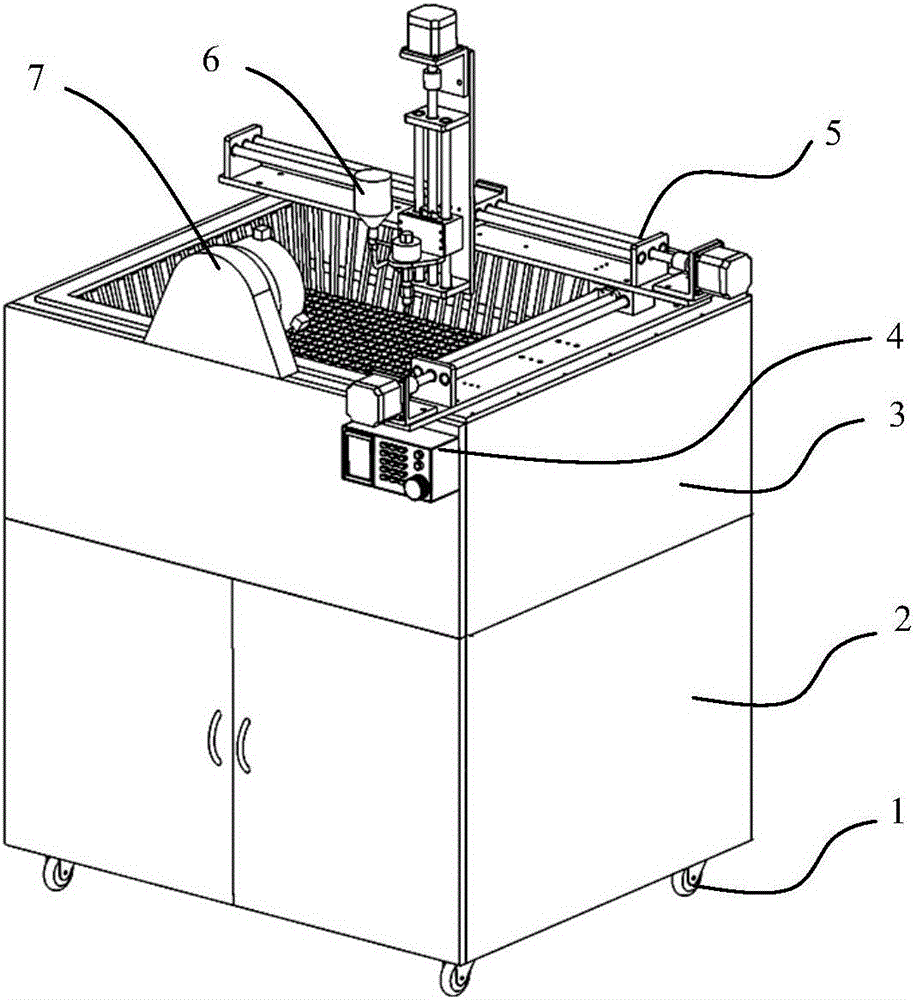

[0025] see figure 1 , the water-cut geological rock sample processing device of the present invention mainly includes a universal wheel 1, a lower box 2, an upper box 3, an integrated control box 4, a three-axis linear slide 5, a water-cutting system 6 and a hydraulic three-jaw chuck7.

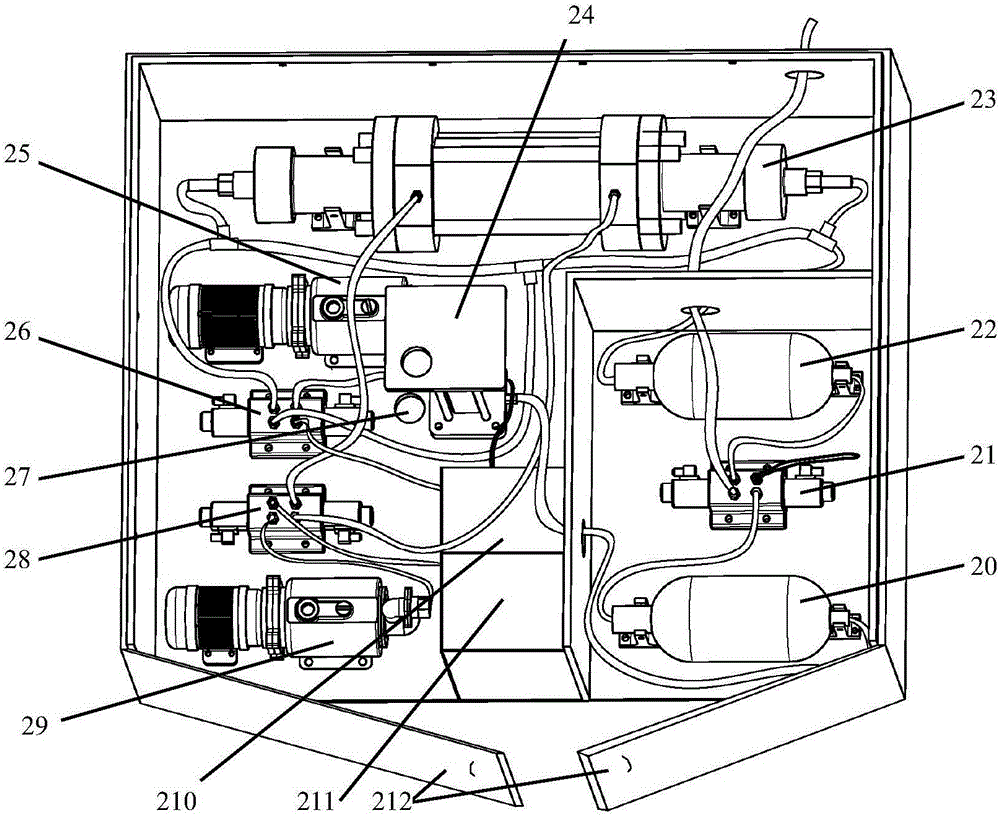

[0026] see figure 2 , the lower box body 2 is in the form of a basic frame external skin, and the lower box body is equipped with a medium and low pressure accumulator 20, a solenoid valve I21, an ultra-high pressure accumulator 22, a booster pump 23, a hydraulic cylinder 24, a water pump 25, an electromagnetic Valve II26, sewage outlet 27, solenoid valve III28, oil pump 29, water return tank 210 and oil return tank 211; the front of the lower box body 2 is provided with an inspection cabinet door 212, so as to adjust the operating status of some equipment during oper

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal pressure | aaaaa | aaaaa |

| Nominal pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap