Novel clamp for welding metal packaging box accessories

A metal packaging and fixture technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve problems such as large errors, achieve the effects of low manufacturing cost, conducive to large-scale popularization and use, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

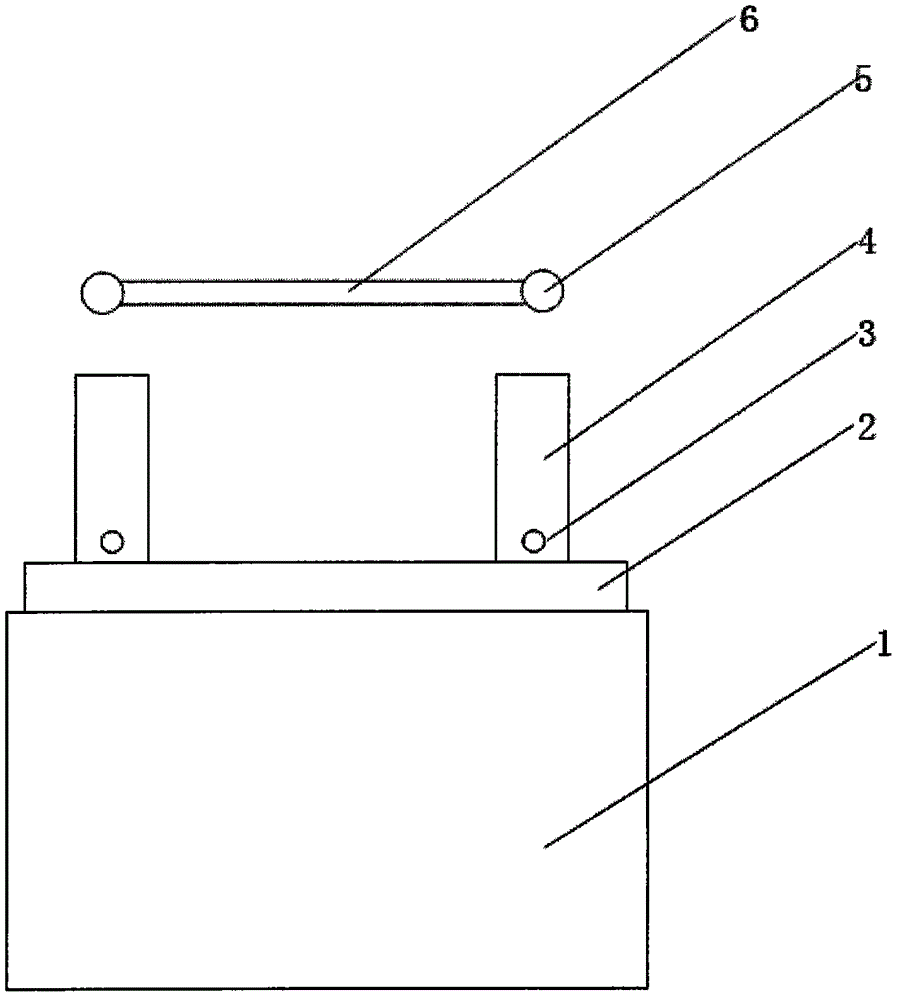

[0008] Such as figure 1 As shown, a new type of fixture for metal packaging box accessories welding with reasonable design, high work efficiency and convenient use according to the present invention includes a fixed seat 1, and a slide rail 2 is arranged on the fixed seat 1. Two parallel vertical clamps 4 are arranged side by side on the slide rail 2 , and the bottom of the vertical clamps 4 is provided with an adjusting bolt 3 which can adjust the tightness of the clamps.

[0009] A new type of fixture used for welding metal packaging box accessories described in this patent, through the completely parallel arrangement of two vertical fixtures 4, when in use, the balance shaft head 6 that has welded an I-shaped joint 5 can first pass through a The vertical clamp 4 clamps the I-shaped joint 5 vertically, and then vertically clamps the other unwelded I-shaped joint 5 with another vertical clamp 4, and then performs the welding operation, which can ensure the balance of the shaft h

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap