Mechanism used for storing drinks on buggy

An ATV and beverage technology, which is applied to the field of mechanisms for storing beverages on ATVs, can solve problems such as inconvenience for drivers, and achieve the effects of avoiding air-conditioning loss, stabilizing the environment, and being convenient to take out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

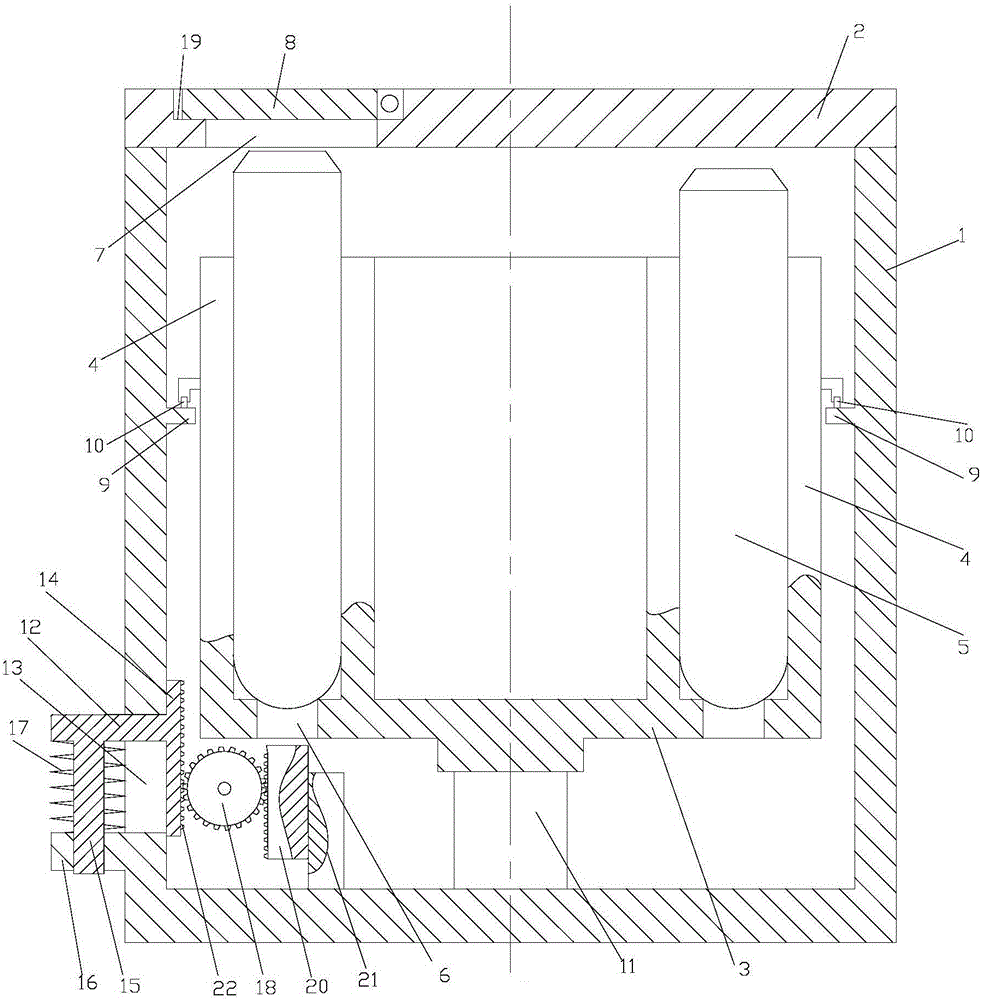

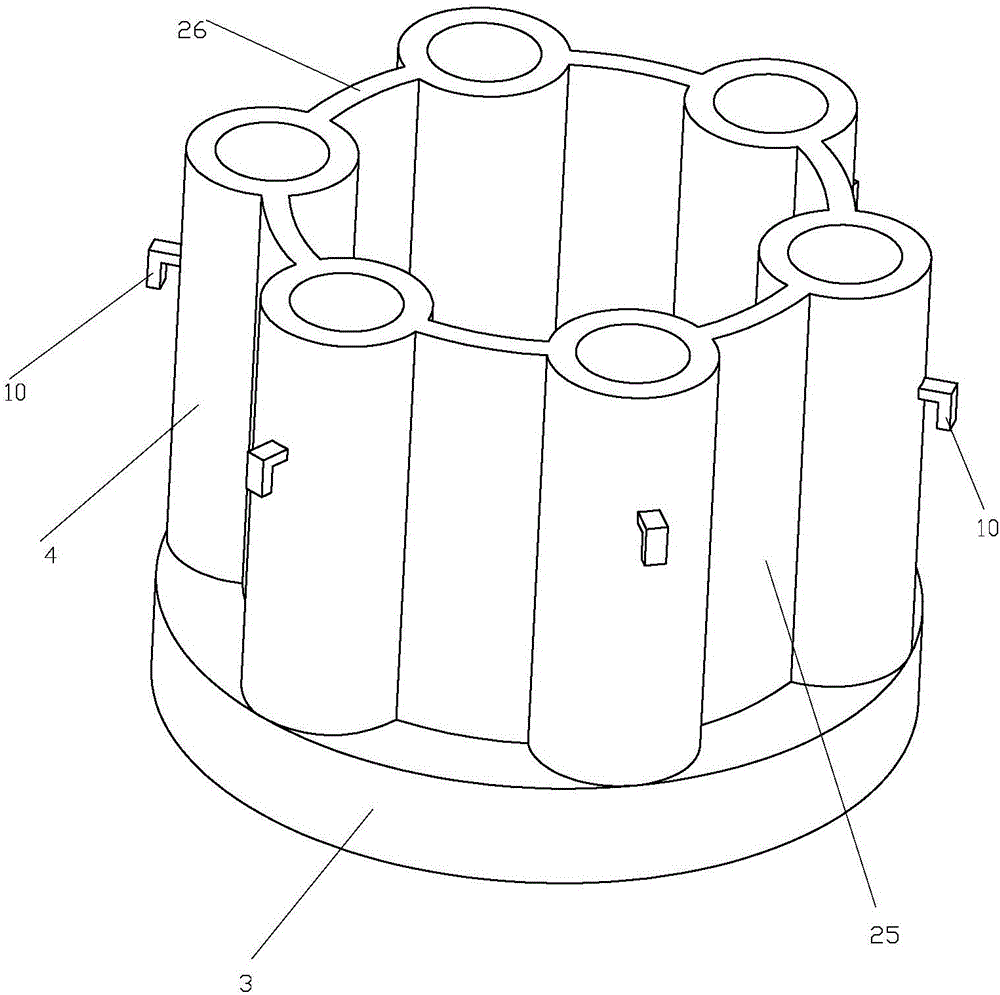

[0013] The working principle of the present invention: the motor 11 drives the turntable 3 to rotate in the box body 1, and pushes the beverage bottles 5 on the turntable 3 to the right below the second through hole 7 one by one; The roller 10 can roll on the annular boss 9, so as to support the bracket 4 when it rotates, and prevent the bracket 4 from turning over and causing transmission failure;

[0014] When the beverage bottle 5 is located directly below the second through hole 7, the operator steps on the left end of the cross bar 12, the first vertical bar 14 and the second vertical bar 15 descend along the through hole on the projection 16 and squeeze the stage clip 17. The first linear rack 22 descends synchronously with the first vertical rod 14, the first linear rack 22 drives the second linear rack 20 to rise through the gear 18, and t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap