Production equipment and preparation method of carbon composite

A technology for carbon composite materials and production equipment, which is applied in the field of carbon composite material production equipment and its preparation, can solve the problems of resource waste, low recovery rate, and impact on rural environmental sanitation, so as to reduce preparation costs, improve adsorption performance, and expand The effect of the application path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The present invention will be further explained below in conjunction with the drawings:

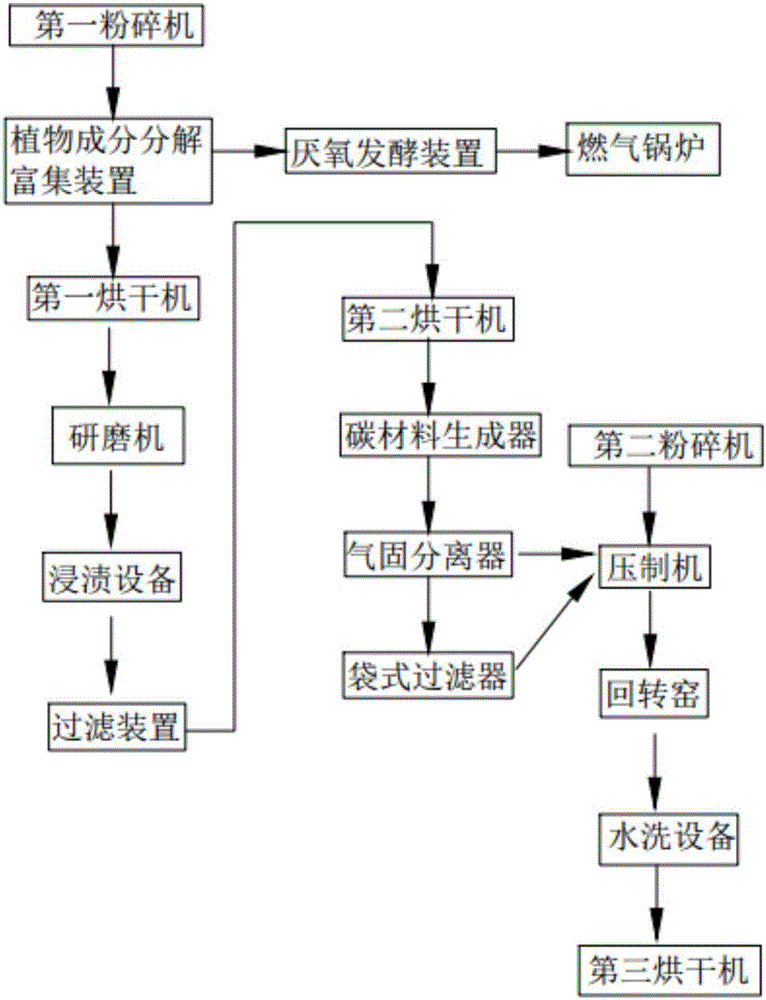

[0025] Such as figure 1 As shown, a production equipment for carbon composite materials includes a first grinder, a plant component decomposing and enriching device, an anaerobic fermentation device, and a gas boiler connected in sequence, and the plant component decomposing and enriching device is also sequentially connected to the first dryer. Dryer, grinder, impregnation equipment, filtering device, second dryer, carbon material generator, gas-solid separator, bag filter, the gas-solid separator and bag filter are both connected to the press, The pressing machine is also connected to a rotary kiln, a water washing device and a third dryer in sequence; it also includes a second crusher, which is connected to the pressing machine. The metal rod, the quartz inner tube, and the quartz outer tube are arranged vertically in turn from the inside out, the outer wall of the quartz outer tube i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap