Bench and method for testing heat conductivity coefficient of heat exchange tube of EGR cooler

An EGR cooler and thermal conductivity technology, applied in the direction of material thermal development, etc., can solve the problems of destroying the heat exchanger tube, reducing the heat exchange efficiency of the cooler, and difficult to measure the thermal conductivity of the heat exchanger tube. Simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

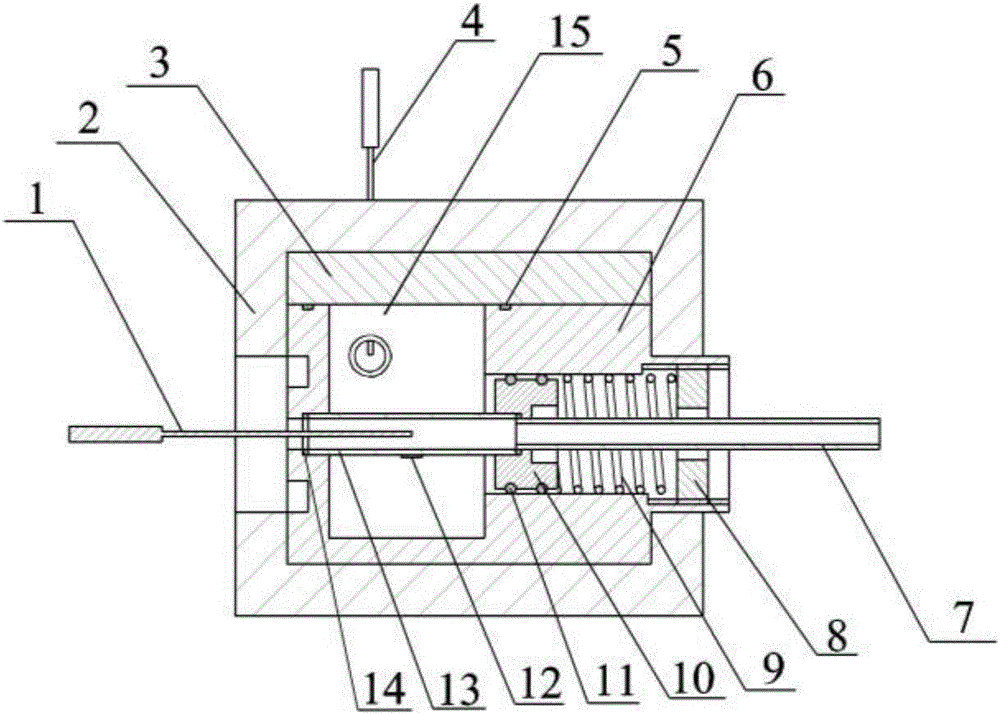

[0025] Such as figure 1 As shown, a test bench for thermal conductivity of heat exchange tubes of an EGR cooler includes a base body 6, a water storage chamber 15, a piston 10, and a spring fixing bolt 8; the base body 6 is an external sealing structure, and the inner left side is provided with a water storage chamber 15 , the right side is provided with a piston chamber and a spring fixing bolt 8 connected in sequence; the piston chamber is provided with a piston 10 and a spring 9, and the spring 9 is arranged on the right side of the piston 10; the spring 9 is connected to the spring fixing bolt 8 on the right side; the heat exchange tube 13 is set in the water storage chamber 15 of the base body 6, the air inlet end is externally connected to the base body 6, and the air outlet end is externally connected to the piston 10; the air outlet end of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap