Control device of exhaust valve

A technology for control devices and exhaust valves, applied in valve devices, valve operation/release devices, valve details, etc., can solve problems such as unreliable feedback signals and poor anti-vibration capabilities, and achieve the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

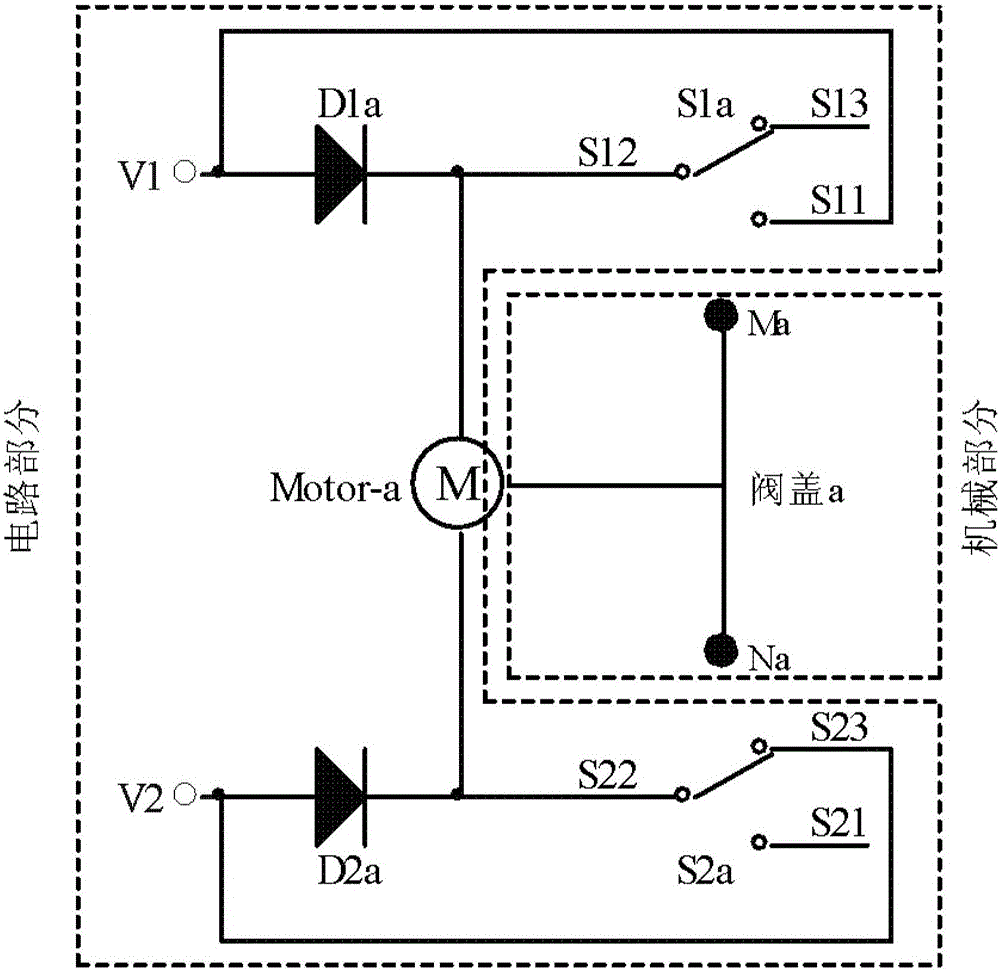

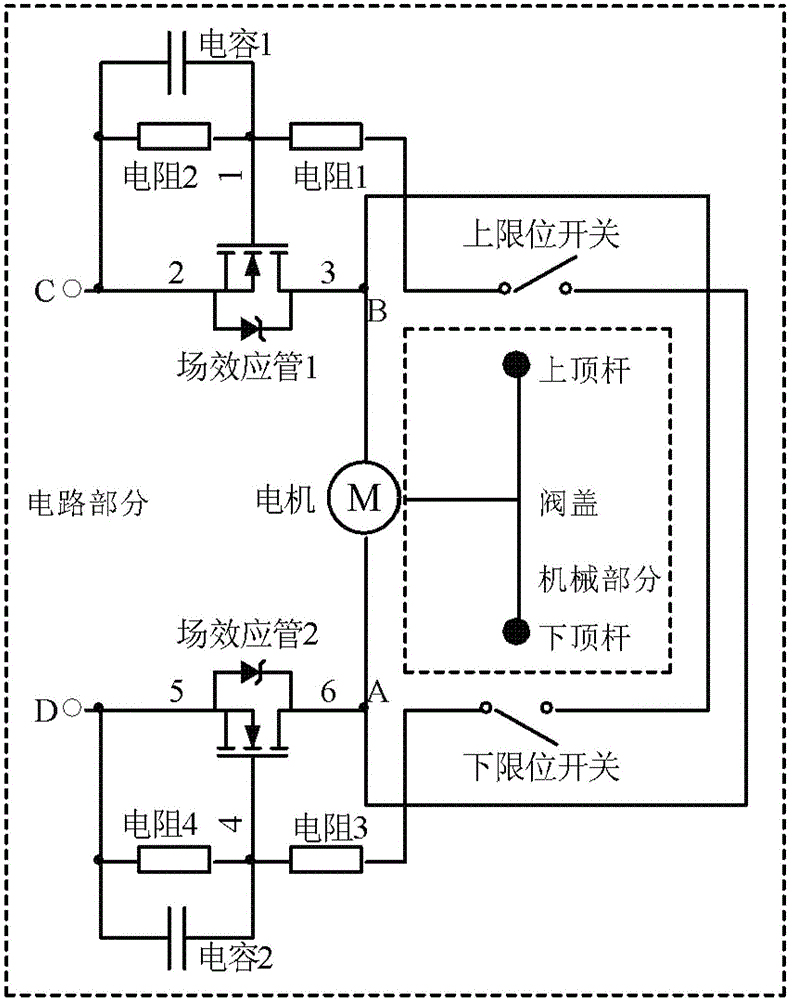

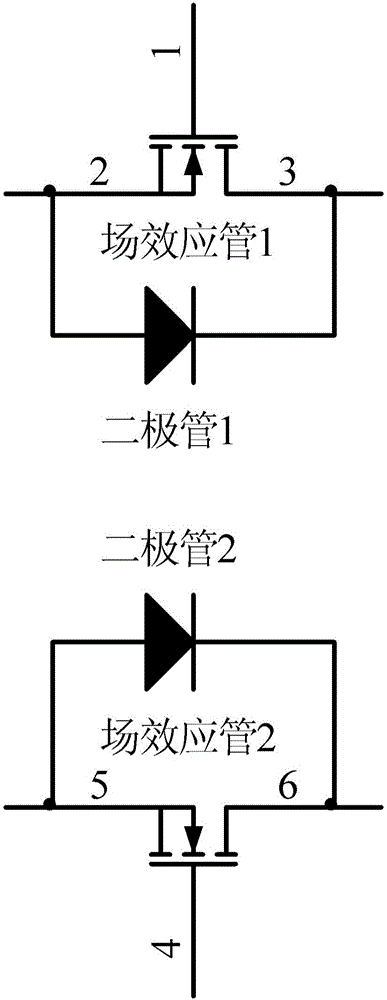

[0025] The invention provides a control device for an exhaust valve, which is used to control the movement of the valve cover of the exhaust valve, thereby opening or closing the exhaust valve. The device includes a power supply, a control circuit, a motor and a mechanical part, and the power supply supplies power to the motor, In order to make the motor drive the mechanical part to move, so that the mechanical part drives the valve cover to move; when the mechanical part moves to a fixed position in a certain direction, the mechanical part triggers the control circuit, and the control circuit controls the power supply to continue to supply power to the motor for a period of time and then power off.

[0026] Wherein, before the control circuit is triggered by the mechanical part, the power supply charges the control circuit, and after the control circuit is triggered by the mechanical part, it discharges, so that the power supply continues to supply power to the motor until the con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap