Sleeve scraper and cleaning method adopting same

A pipe scraper and casing technology, which is applied to cleaning appliances, earth-moving drilling, wellbore/well components, etc., can solve problems such as affecting the setting of packers, and achieve the effect of improving work efficiency and reducing the risk of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

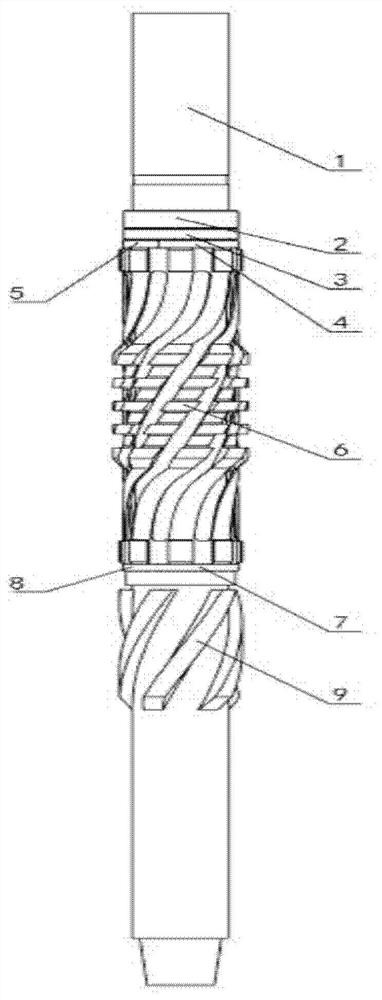

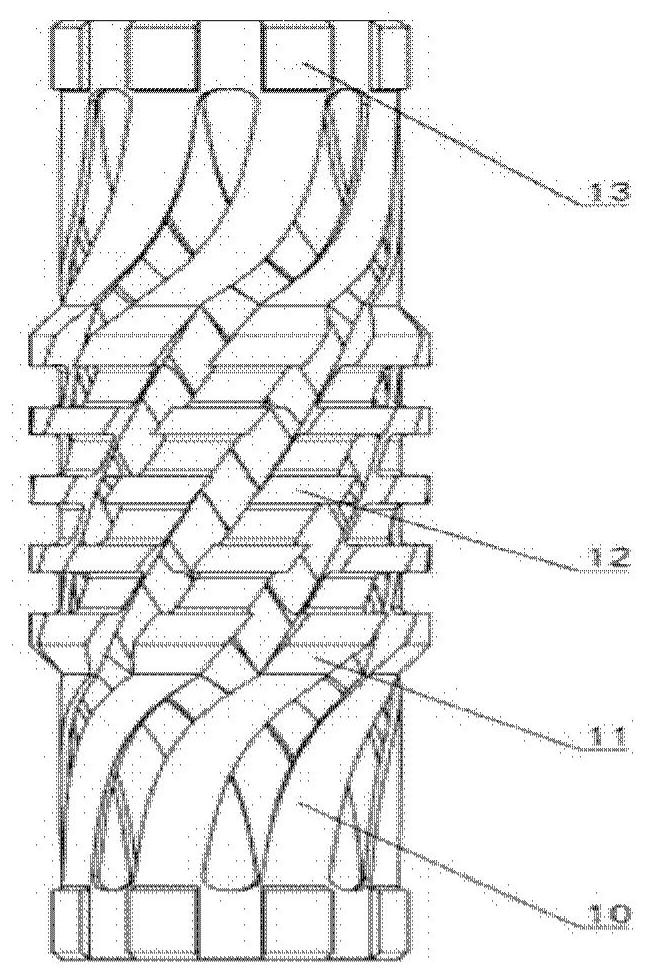

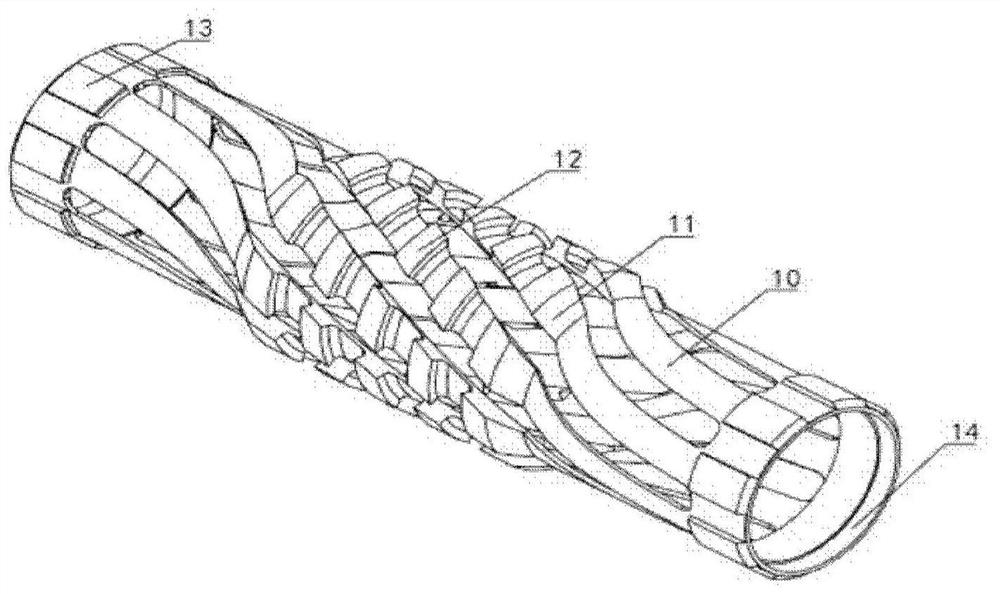

[0027] In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. Since the location of the product placed in the present invention can change at will, "" "," "" "," "left", "right" or equal correspondence as described in the present invention represents only relative positional relationships, not to limit absolute The location relationship. In the following description, in order to describe convenience, reference figure 1 The sleeve scraper of the present invention uses a vertical placement (the paper is seen from top down), and the upper joint is located above, and the lower joint is located below.

[0028] The present invention discloses a sleeve scraper, which is a monolithic mandrel-axis-viable type cage sleeve scraper, including:

[0029] The integral mandrel, which is a whole, interior and up and down;

[0030] Cage scraper, the cage scr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap