Capacitor element detection device and method

A detection device and capacitor technology, applied in the field of capacitors, can solve the problems of increasing labor intensity, increasing manpower and time, affecting production efficiency, etc., and achieving the effects of improving production efficiency, saving time and manpower, and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

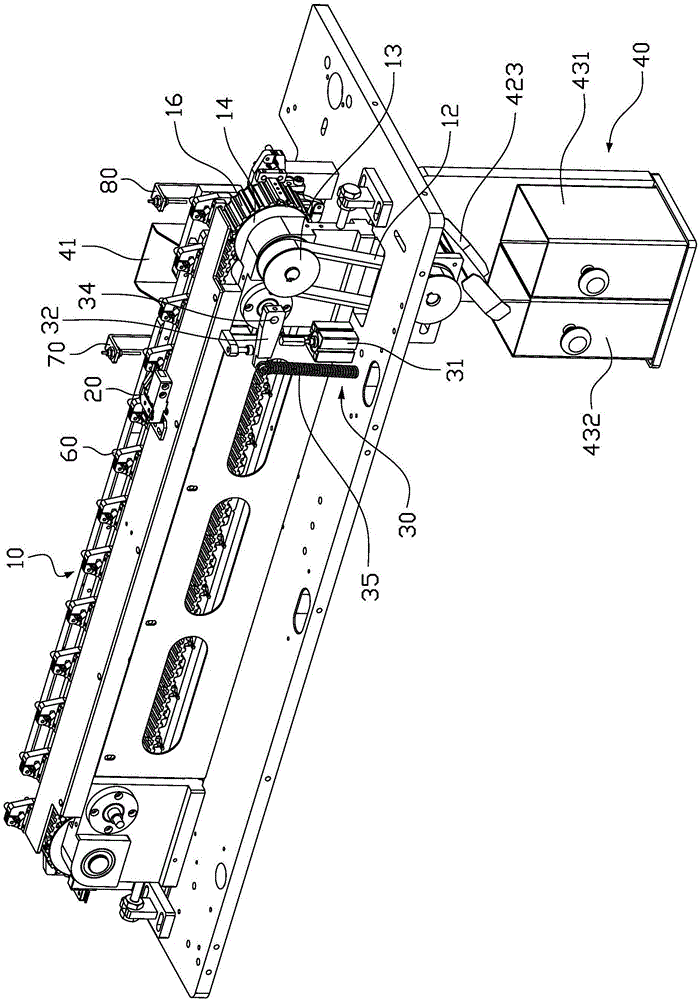

[0026] The capacitor element detection device in the embodiment of the present invention is used to automatically perform short circuit detection, Polarity detection and bud detection. Such as figure 1 and figure 2 As shown, the capacitor element detection device according to the embodiment of the present invention includes a conveying mechanism 10, a first detecting mechanism 20, a swing arm mechanism 30 and a waste recycling mechanism 40. The first detecting mechanism 20 and the swing arm mechanism 30 are along the conveying direction of the conveying mechanism 10. Arranged in sequence, the waste recovery mechanism 40 is located below the swin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap