Automatic skin feeding machine

An automatic and transmission technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of improvement, unfavorable product quality, complex skin embedded structure, etc., to achieve compact structure, stable operation, safe and reliable, and melting effect. better ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

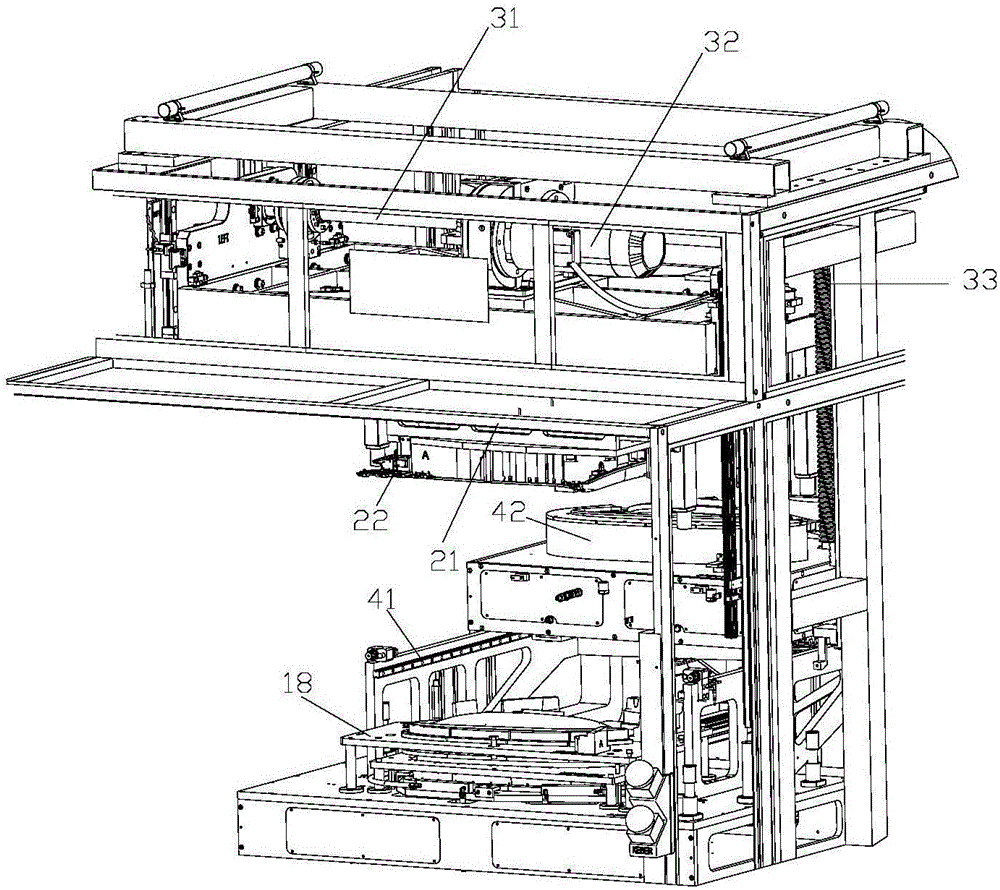

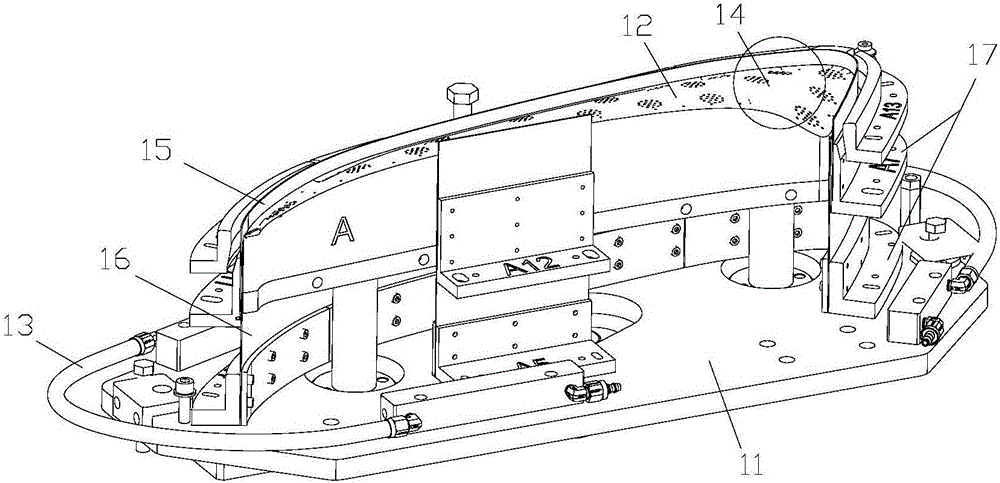

[0017] Please refer to the attached Figures 1 to 4 , the embodiment of the present invention includes:

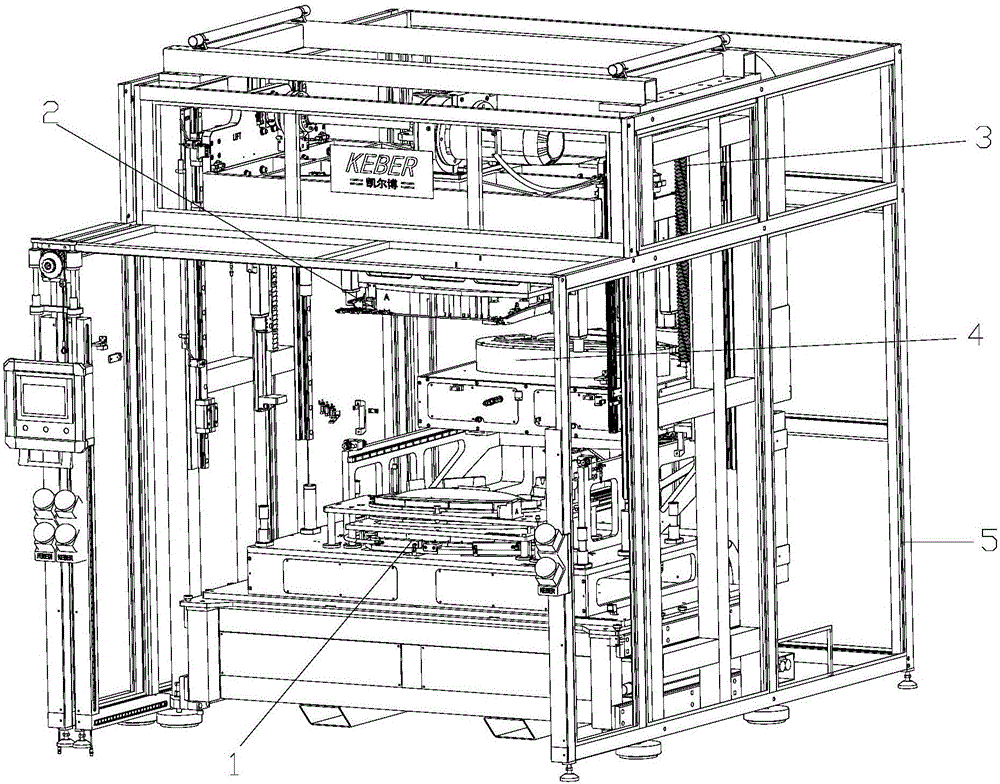

[0018] An automatic eye-entrying machine includes: an upper mold device 2 , a lower mold device 1 , a transmission device 3 and a heating device 4 arranged in a frame. The frame 5 is a frame structure formed by butting a series of profiles. The upper mold device 2 is fixed on the top of the frame 5, and the lower mold device 1 is fixed on the bottom of the frame 5. The upper mold device 2 and the lower mold device 1 are opposite to each other. And design, and transmission device 3 is then positioned at the side of frame 5, and the outside of fr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap