Multi-vision magnetic ring defect detection method and multi-vision magnetic ring defect detection system

A multi-eye vision and detection method technology, applied in optical testing flaws/defects, measuring devices, image data processing, etc., can solve the problem of damage to the magnetic ring, accuracy, stability and detection speed are difficult to meet production speed and requirements, missed judgments , misjudgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0053] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

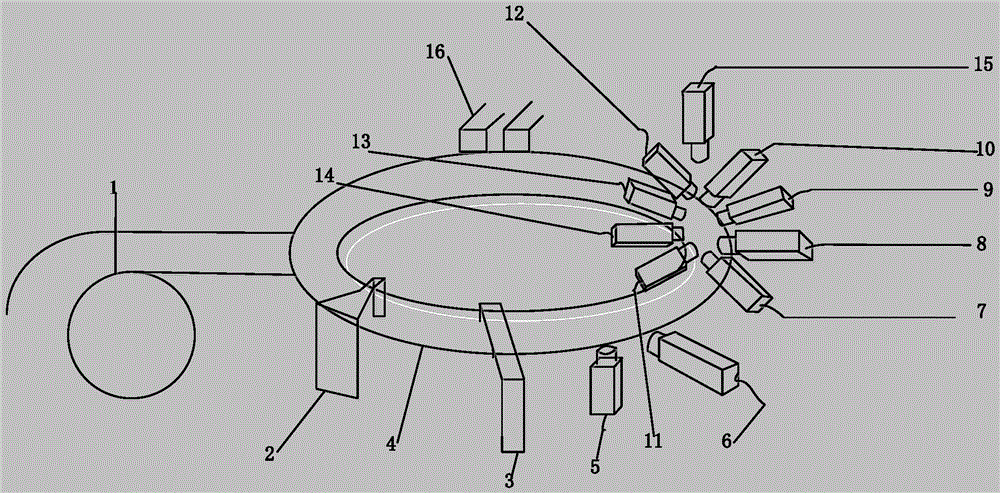

[0054] Such as figure 1 with figure 2 As shown, the ring-shaped vibrating table 1 uses a conveyor belt to send the magnetic ring to the ring-shaped rotating device 4; the magnetic ring position fixing device 2 is located above the ring-shaped rotating device 4, and there are shields and fixed objects along the radial direction of the ring-shaped rotating device 4. The constraining magnetic ring makes a constant circular motion with a fixed radius on the annular rotating device 4 along with the annular rotating device 4. The magnetic ring is placed on the annular rotating device. The annular rotating device is transparent to ensure that the bottom surface of the magnetic ring can be used by the camera 5. Photographed. At the same time, fix the annular rotating device 4 to prevent it from shaking;

[0055] The infrared pulse camera trigger device 3 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap