Coarse-grained soil high-filled roadbed drainage structure and construction technique thereof

A technology of drainage structure and construction technology, applied in the field of coarse-grained soil high-fill roadbed drainage structure and its construction technology, can solve the problems of not considering the influence of traffic load on the roadbed soil, unable to protect the roadbed, erosion, etc., and achieve the drainage effect. Good, high compressive strength, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

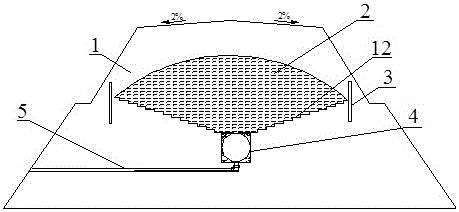

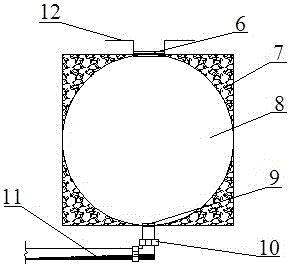

[0012] The structural combination mode and implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , figure 2 Shown are the sectional view of the drainage structure of the high-filled roadbed with coarse-grained soil and the structure diagram of the drainage device. The drainage structure of the roadbed includes: roadbed (1), fiber soil (2), retaining wall (3), drainage device (4), horizontal drainage pipe (5), filter geotextile (6), open graded gravel (7), longitudinal drainage pipe (8), counterflow valve (9), rubber ring interface (10), gelling Material (11), anti-seepage geotextile (12); wherein the fiber soil (2) is blended with coarse-grained soil and a certain proportion of geotextile absorbent fiber material, wherein the quality of the absorbent fiber is 0.2%, so An impermeable geotextile (12) is laid on the lower part of the fiber soil (2), and only an interface is provided betwe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap