Novel rail-mounted festoon pulley system and mounting method thereof

A track-type, trolley technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of reduced site utilization, reduced plant utilization, increased production costs, etc., to achieve improved site utilization and blind areas of plant use. Reduce, use the effect of reducing the dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

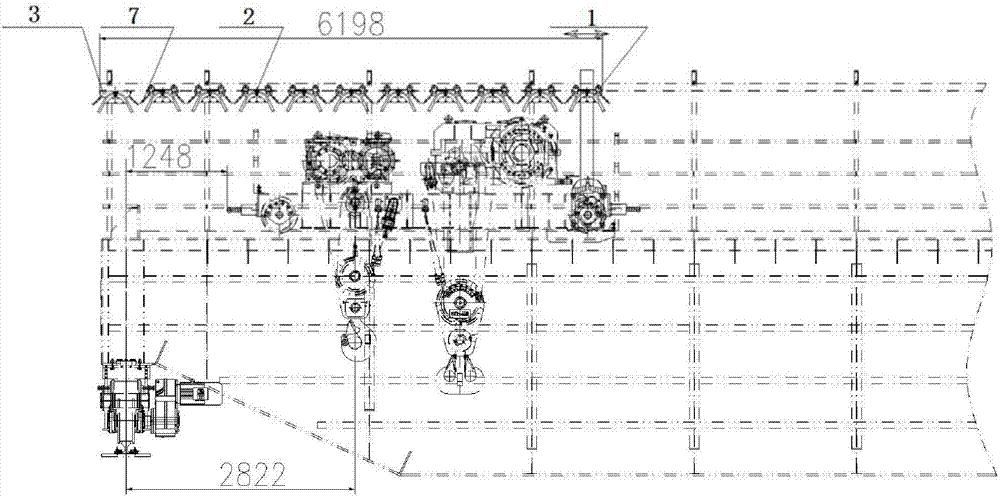

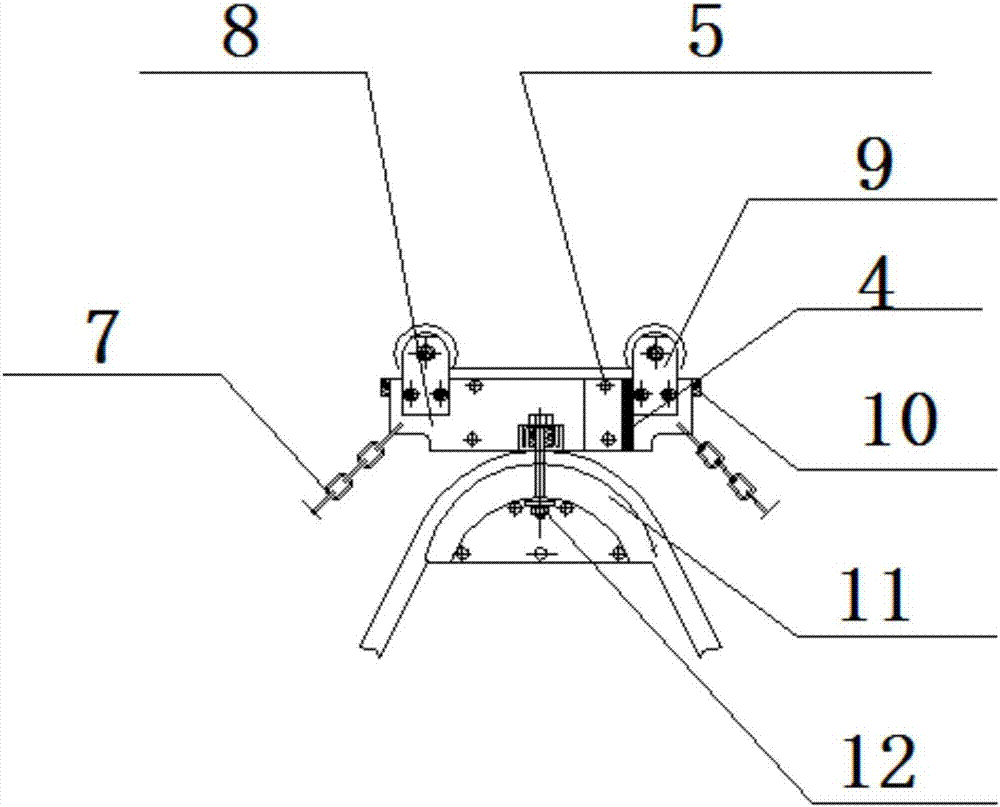

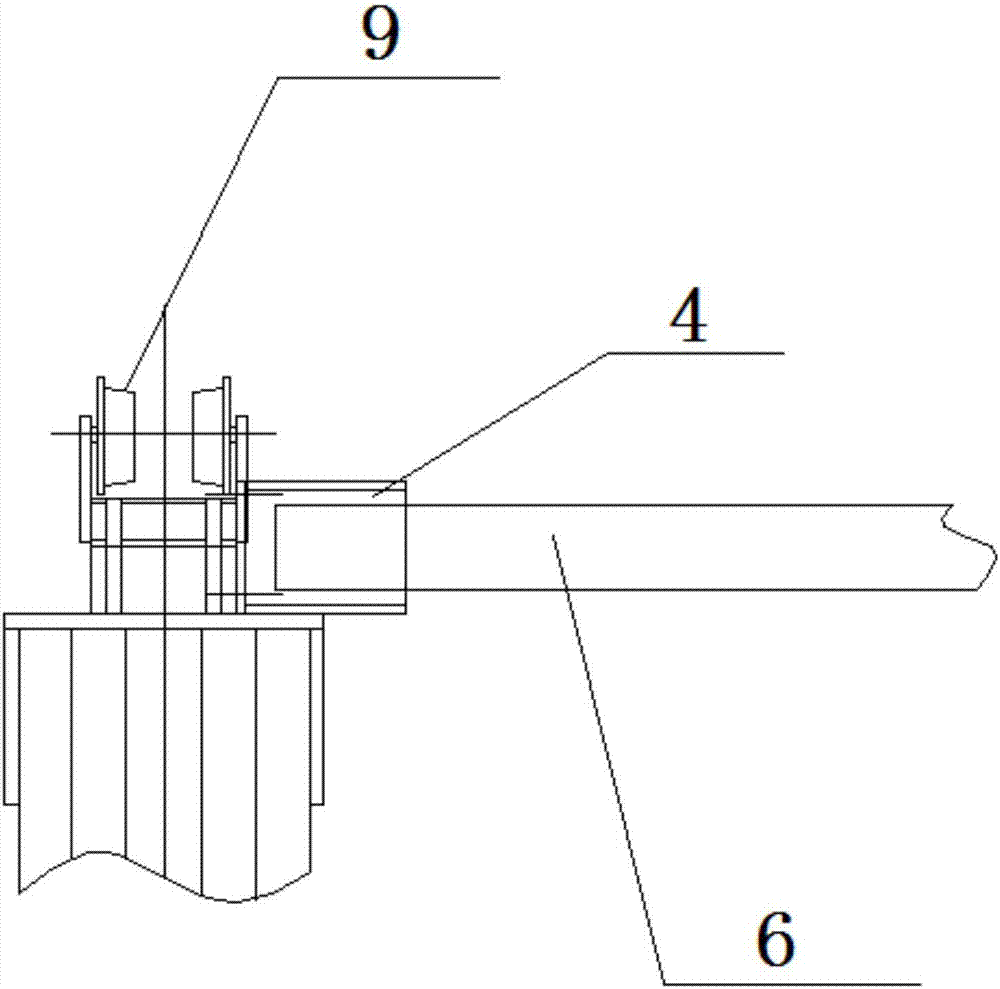

[0025] Example: such as Figure 2-4 A novel track-type towing tackle system and its installation method shown include at least three tackles connected by traction chains, including a fixed tackle and a moving tackle. There is only one fixed tackle 3, and the rest are moving tackles , the moving block is divided into a head car 1 and a middle block 2, and the middle block 2 includes a traction middle block; wherein, the moving block is provided with rack mounting holes, and the head block 1 and the middle block in the moving block The traction intermediate block is provided with a rack 4 installed in the mounting hole of the rack, and at the same time, it also includes a drag bar 6 used in conjunction with the rack, and the drag bar is installed on the trolley of the crane, wherein , the drag rod 6 is used as the input power source device of the trolley system, and the gear frame 4 is the power source device for receiving.

[0026] In this embodiment, also taking the 46m-span wor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap