Overflow type lead-acid storage battery formation water bath

A lead-acid battery, overflow type technology, applied in water bath, flooded lead-acid battery into water bath field, to achieve the effect of reducing labor intensity, stable quality, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

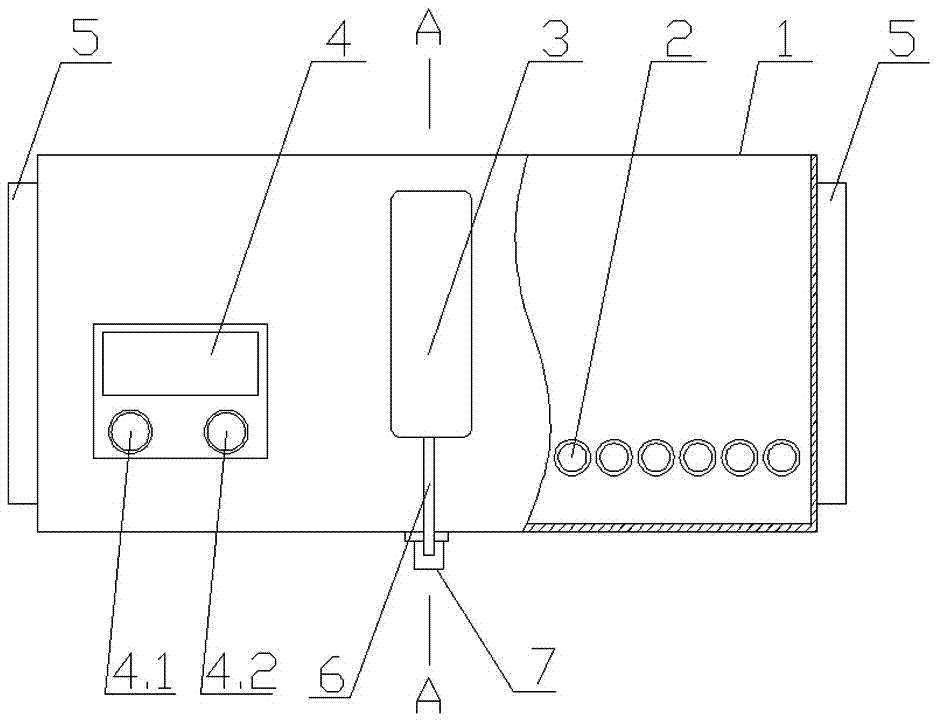

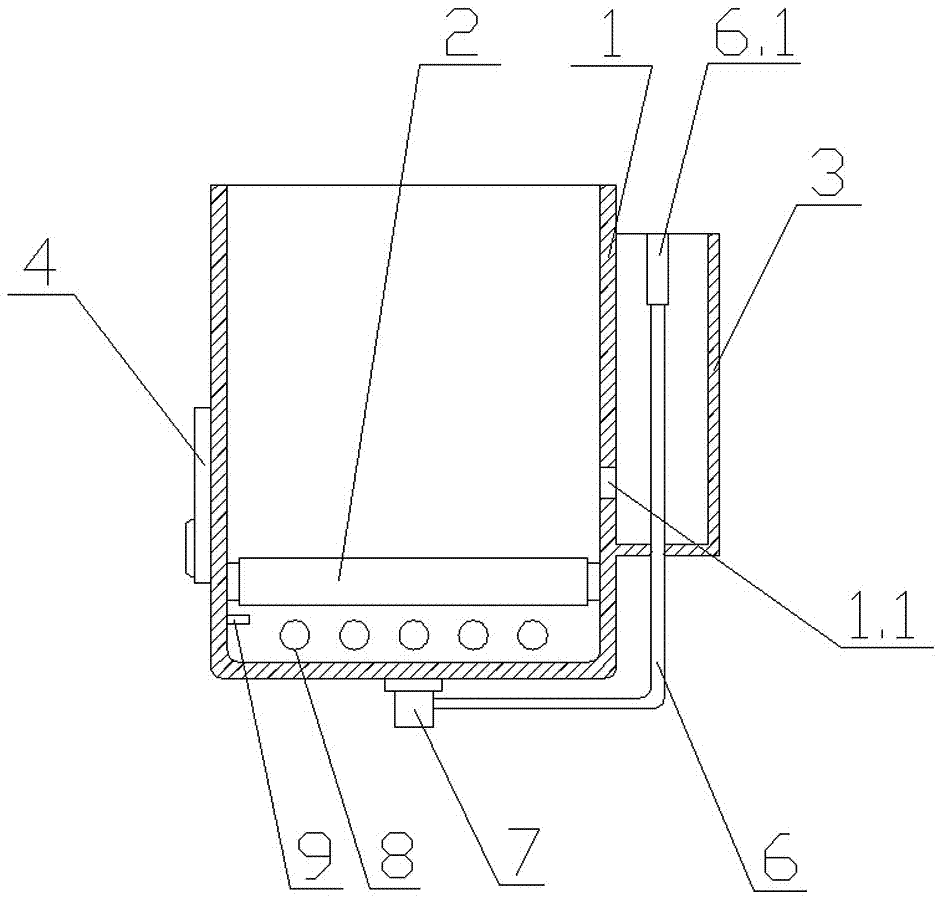

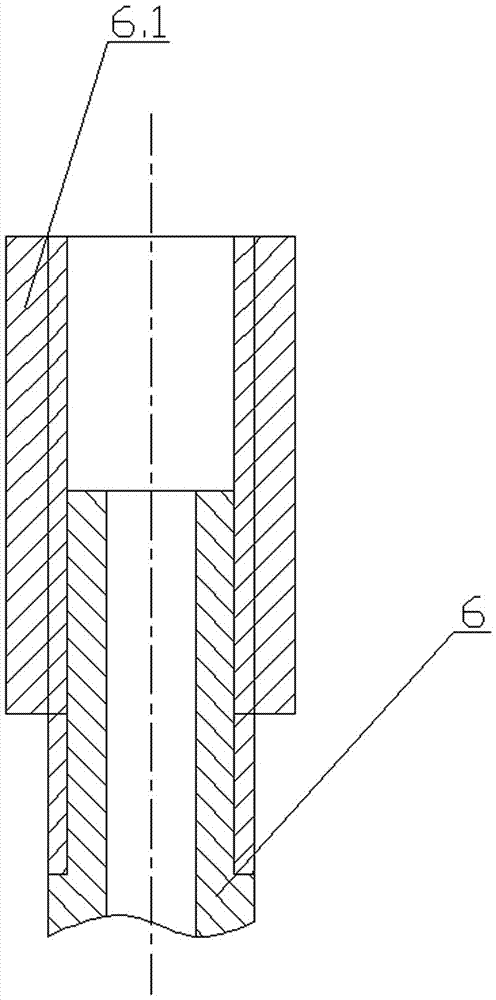

[0018] figure 1 The shown flooded lead-acid storage battery is formed into a water bath, which includes a tank shell 1, a roller shaft 2, a water tank 3, a temperature controller 4, a gate 5, a discharge pipe 6, a drain port 7, a heating pipe 8 and a temperature sensor 9 . The tank shell 1 is the main component of the water bath. It is a rectangular container in a lying position. A thermostat 4 is provided on one side of the outer wall, and gates 5 are provided on the walls at both ends of the length. In order to facilitate the displacement of the formed lead-acid battery, a row of roller shafts 2 arranged at equal intervals are arranged horizontally along the length direction at the low position of the inner cavity of the tank shell 1. Both ends of each roller shaft 2 are equipped with bearings to improve the roller shaft. 2. The flexib

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap