Double-shaft driving tundish tipping device

A dual-axis drive and bag tipping technology, applied in the field of iron and steel casting, can solve the problems of bag body distortion and deformation, and achieve the effect of hydraulic drive with large locking force, high safety factor, and reduced installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Embodiments of the present invention will be described with reference to the accompanying drawings.

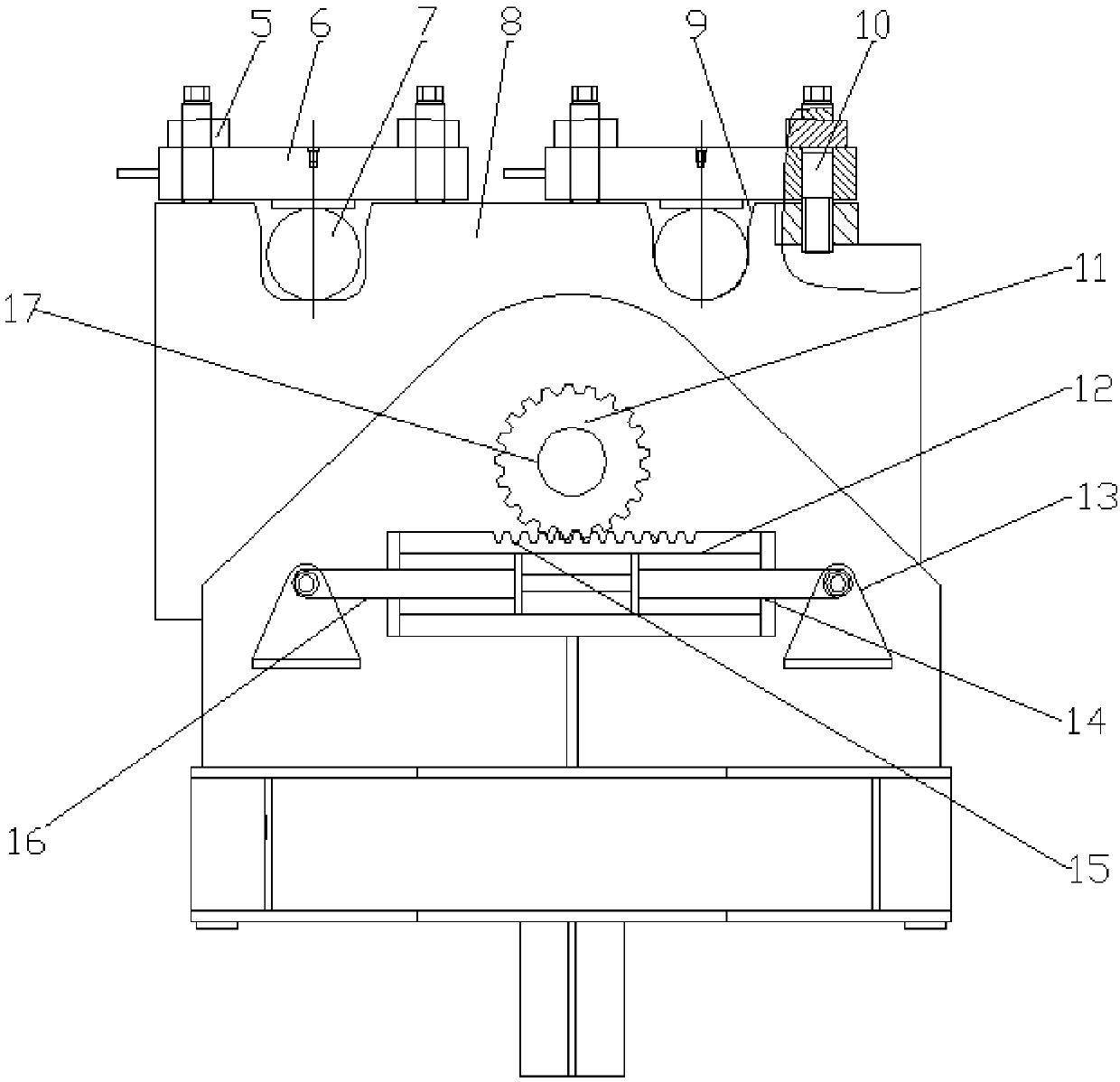

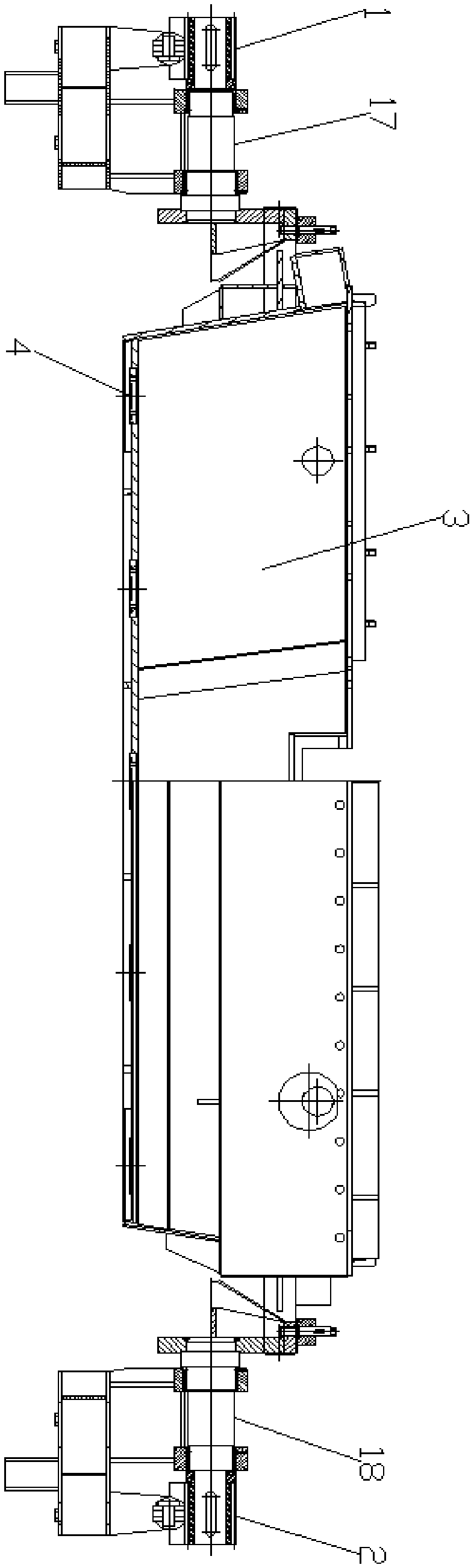

[0031] A dual-axis drive tundish tipping device includes a first drive assembly 1, the first drive assembly 1 includes a base 20, an oil cylinder support base 13 is installed on the base 20, and the oil cylinder support base 13 is fastened on both sides of the base 20 by bolts, It is connected with the first telescopic rod 14 and the second telescopic rod 16 of the double-rod oil cylinder 12 through the pin shaft 21. There are piston cylinders on both sides of the piston of the double-rod oil cylinder 12, which are driven by two-way hydraulic pressure. The rod 14 and the second telescopic rod 16 are hollow double rods, the cross section of the double rod cylinder 12 is square, and the rack 15 is installed on the surface of the cylinder through bolts; the length of the rack 15 is equal to the length of the double rod cylinder 12, and the double rod cylinder 12 The length re

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap