A method for improving methane production performance of anaerobic sludge

A technology for anaerobic sludge and methane production, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low methane production efficiency, achieve excellent methane production performance, improve Methane production performance and the effect of promoting popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

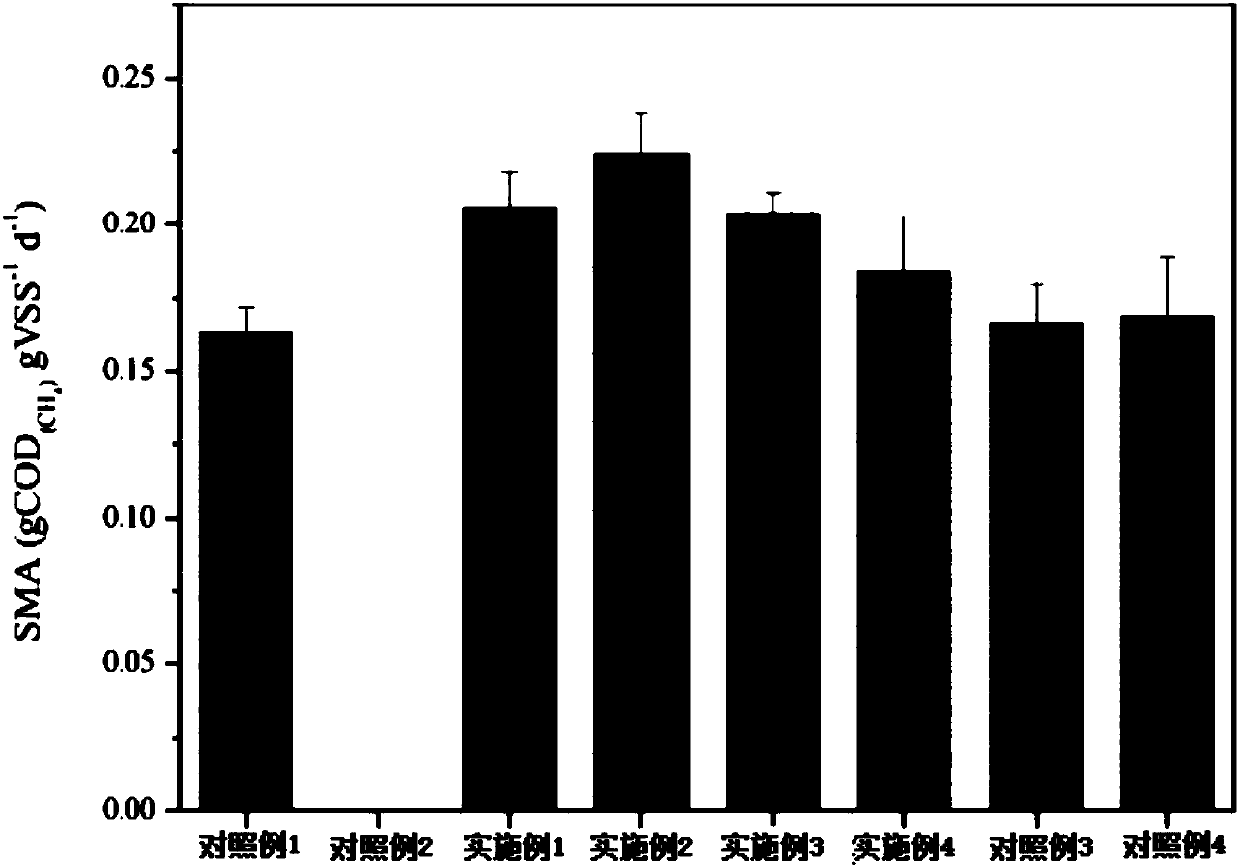

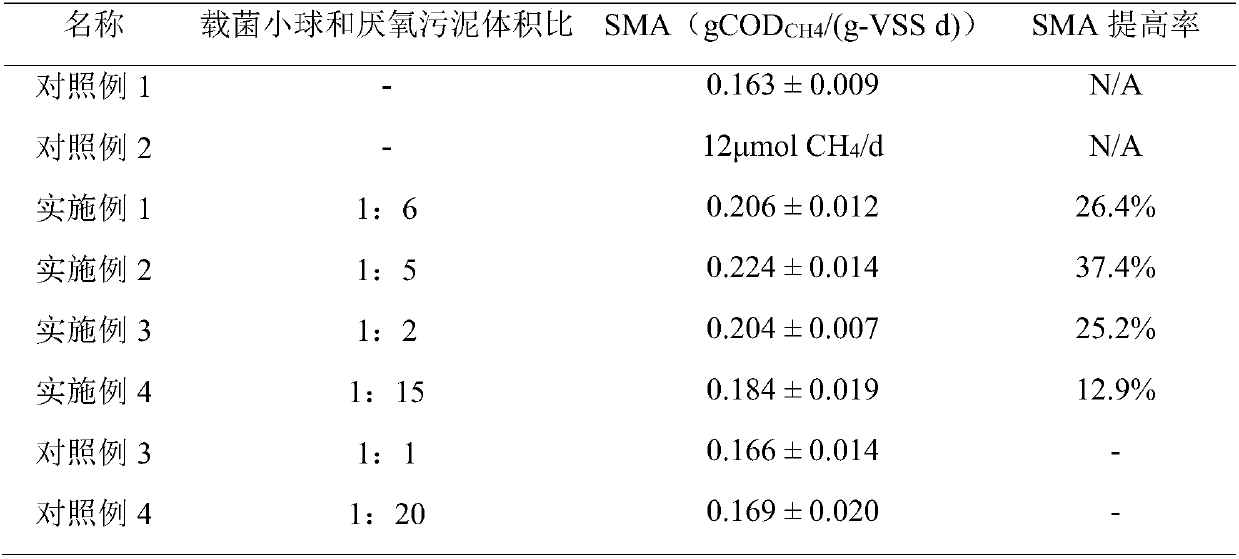

Embodiment 1

[0049] In this embodiment, the specific operation steps of using fungi to improve the methane production performance of the anaerobic sludge system are as follows:

[0050] Step (1), preparing bacteria-carrying pellets. A mixture of polyvinyl alcohol with a mass concentration of 5.5% and sodium alginate with a mass concentration of 3.5% was uniformly mixed with the Aspergillus sydowii bacteria suspension at a volume ratio of 8:1 under anaerobic conditions to prepare a bacteria-containing mixed solution. In an anaerobic environment, the above-mentioned bacteria-containing mixture I was statically dripped at a speed of 5 mL / min into the solution II stirred at a low speed to prepare bacteria-carrying pellets. The composition of the solution II was CaCl 2 Mass concentration is the saturated boric acid solution of 3%; 2 The environment was rinsed with physiological saline for 3 times, and the diameter of the bacteria-carrying pellets was 3-4 mm, presenting a porous microstructure w

Embodiment 2

[0055] In this embodiment, the specific operation steps of using fungi to improve the methane production performance of the anaerobic sludge system are as follows:

[0056] Step (1), preparing fungi-bacteria-carrying pellets. Mix the polyvinyl alcohol with a mass concentration of 6% and the sodium alginate mixed solution with a mass concentration of 3.5% with the Schizophyllum commune bacterial suspension under anaerobic conditions at a volume ratio of 10:1 to make a mixed solution containing bacteria I; The above bacteria-containing mixed solution I was statically dripped into the solution II stirred at a low speed at a speed of 5mL / min under anaerobic environment to prepare bacteria-carrying pellets, and the composition of the solution II was CaCl 2 Mass concentration is the saturated boric acid solution of 4%; 2 The environment was rinsed with physiological saline for 3 times, and the diameter of the bacteria-carrying pellets was 3-4mm, presenting a porous microstructure wi

Embodiment 3

[0060] In this embodiment, the specific operation steps of using fungi to improve the methane production performance of the anaerobic sludge system are as follows:

[0061] Step (1), preparing anaerobic fungi-bacteria-carrying pellets. Mix the polyvinyl alcohol with a mass concentration of 9.5% and the sodium alginate mixed solution with a mass concentration of 5% with the Schizophyllum commune bacterial suspension under anaerobic conditions at a volume ratio of 15:1 to make a mixed solution containing bacteria I; The above bacteria-containing mixed solution I was statically dripped into the solution II stirred at a low speed at a speed of 5mL / min under anaerobic environment to prepare bacteria-carrying pellets, and the composition of the solution II was CaCl 2 The mass concentration is 7% saturated boric acid solution; 2 Rinse with normal saline for 5 times in the environment, and the diameter of the bacteria-carrying pellets is 3-4 mm, presenting a porous microstructure with

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap