Building robot chassis

A construction robot and chassis technology, applied in the field of construction machinery, can solve the problems of complex mechanical positioning structure and high manufacturing cost, and achieve the effect of good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

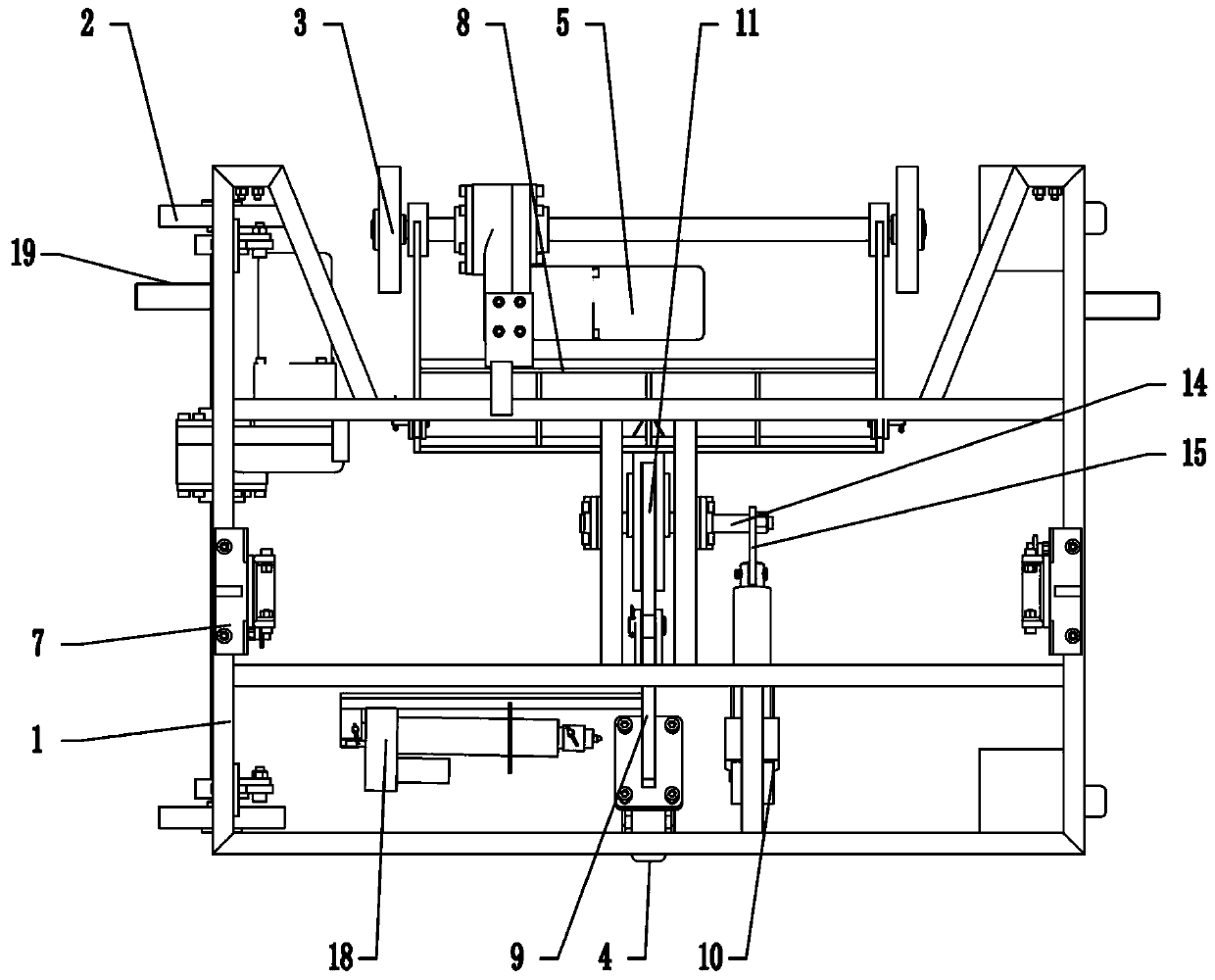

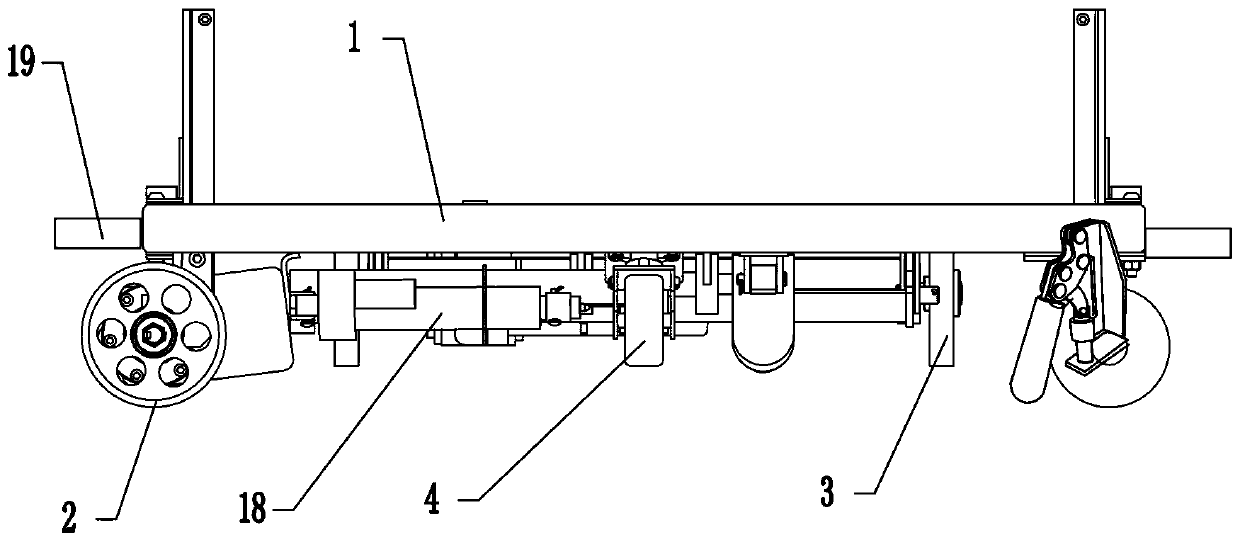

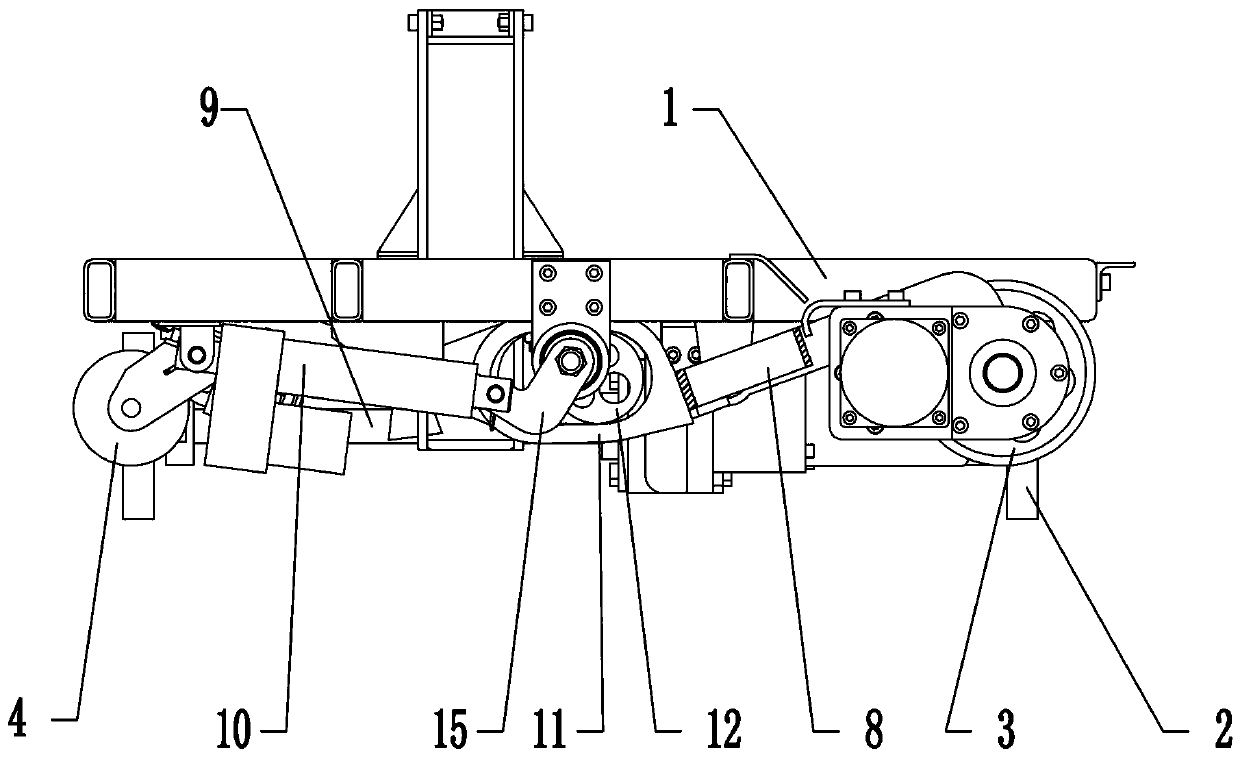

[0023] The invention is suitable for the chassis of the construction robot, and can realize precise adjustment of movement and construction position. The technical scheme adopted in the present invention:

[0024] The construction robot chassis includes a chassis 1, four corners of the chassis 1 are provided with moving wheels 2 that move in the left and right directions, and it is characterized in that a front double-wheel wheel set 3 that can be lifted and lowered at the same time and a rear direction wheel are provided under the chassis 1. 4. The double-wheel wheel set 3 and the direction wheel 4 move forward and backward, the double-wheel wheel set 3 is coaxially driven, the rotating shafts of the double-wheel wheel set 3 and the direction wheel 4 are set on the wheel train lifting frame, and the wheel train lifting frame is provided with Drive the motor 5 of two-wheel wheel group 3, direction wheel 4 directions can rotate, and the steering shaft of direction wheel 4 is provi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap