Battery power supply system for building automatic cargo delivery system trolley

A technology for power supply systems and trolleys, applied in battery circuit devices, transmission systems, electric vehicles, etc., can solve problems such as power supply costs, and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

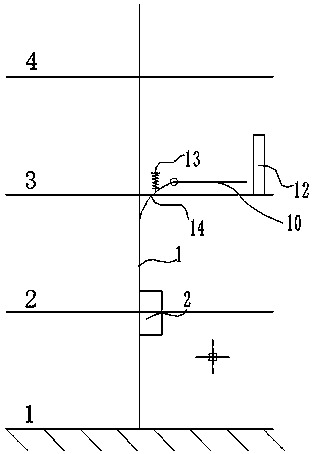

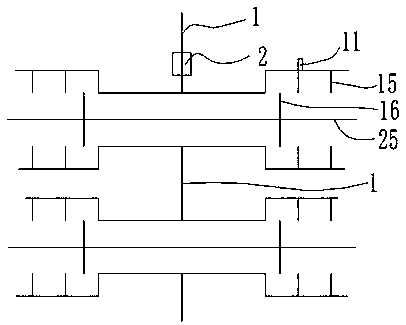

Embodiment 1

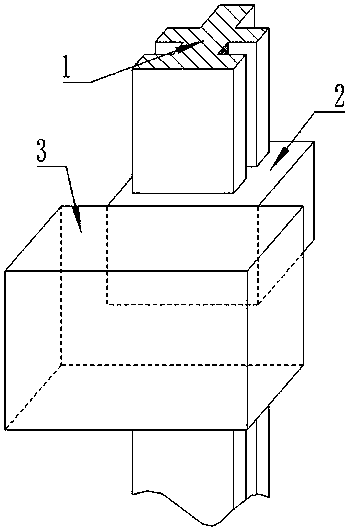

[0036]On the basis of the above embodiments, a preferred trial mode for the battery-powered system of the building automatic delivery system car is also disclosed. The cable plug 7 includes a plug shaft 22, and the plug shaft 22 is sleeved with several diameters Different conductive rings 23, the conductive rings 23 do not overlap each other, the conductive rings 23 are separated by insulating rings 24, the diameter of the conductive rings 23 gradually increases from the top of the plug shaft 22 downwards, and the conductive rings 23 are connected with cable.

[0037] Described cable jack 11 comprises jack housing 17, and hole housing 17 is cylindrical, and hole housing 17 inner wall is provided with some contact columns 18, and contact column 18 is all connected with wire; Column 20, the movable column 20 is connected to the contact column 18 by a spring 19, the top of the movable column 20 is movably connected with a friction wheel 21, and the friction wheel 21 can rotate freel

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap