Insulating blocking head with sensing function

A technology of functions and plugs, which is applied in the field of insulating plugs with sensing functions, can solve the unfavorable problems of miniaturization, complicated wiring, and heavy weight of the ring main unit, and achieve the effects of light weight, small size, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Further description will be made below in conjunction with drawings and embodiments.

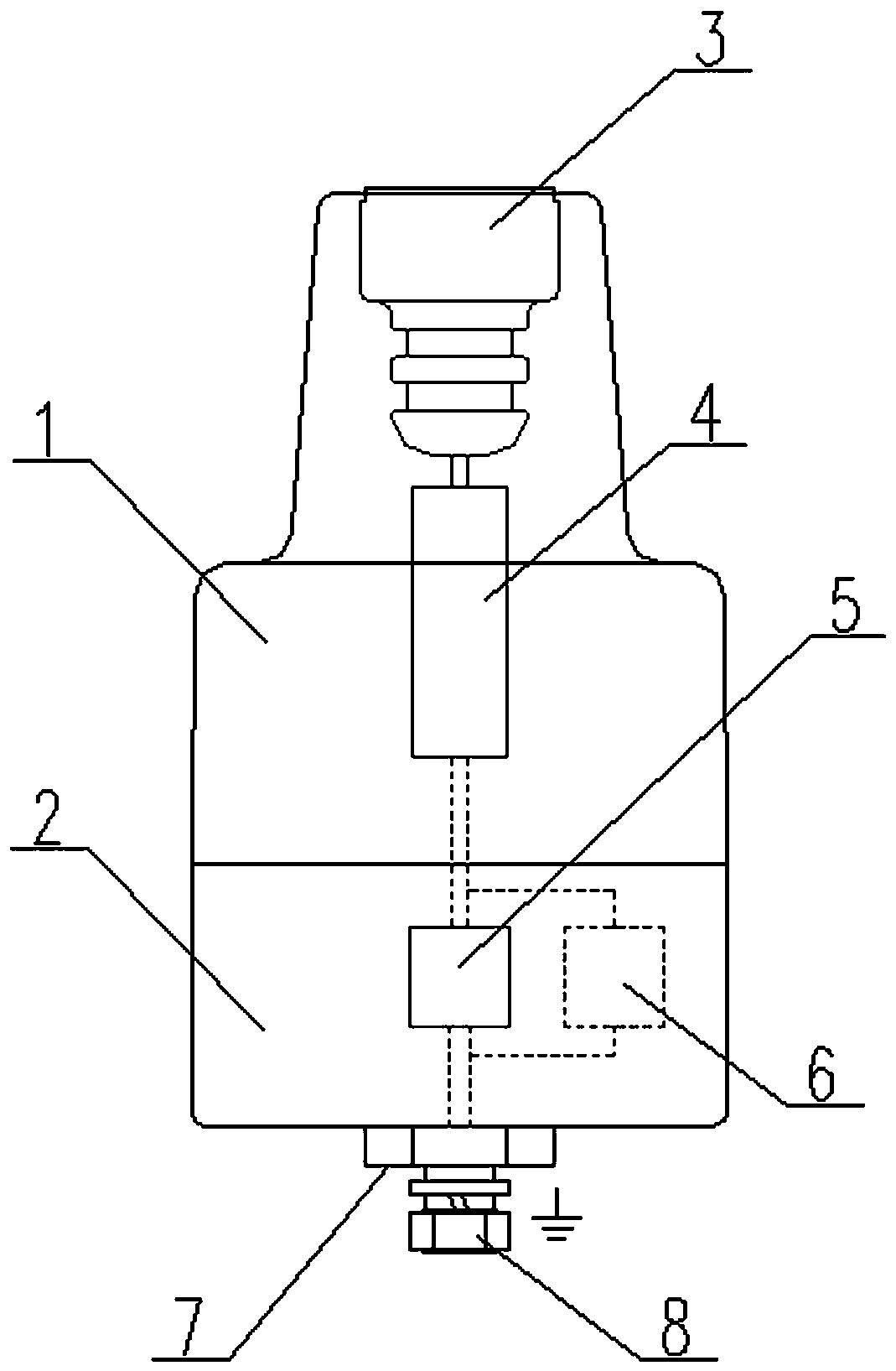

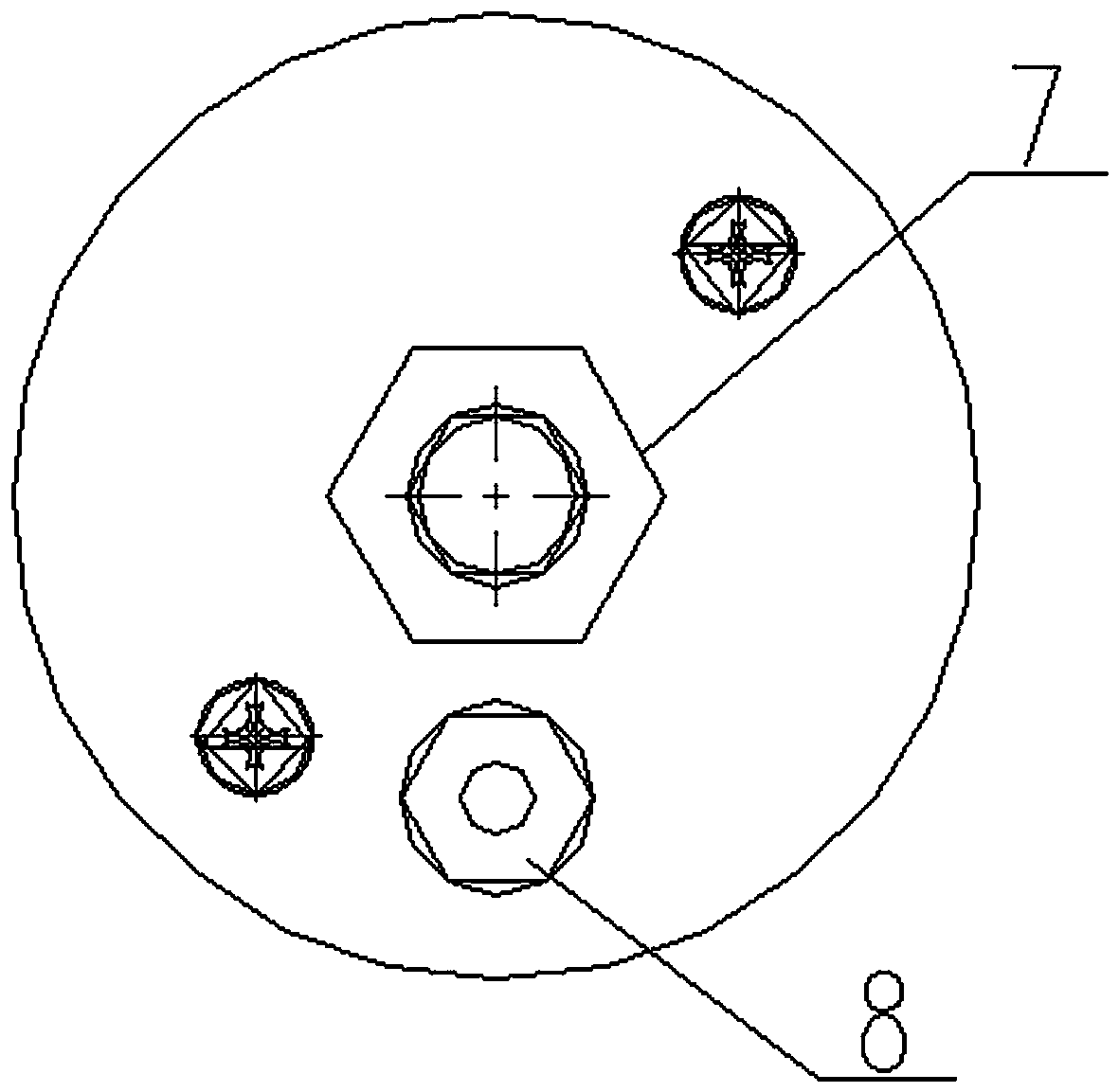

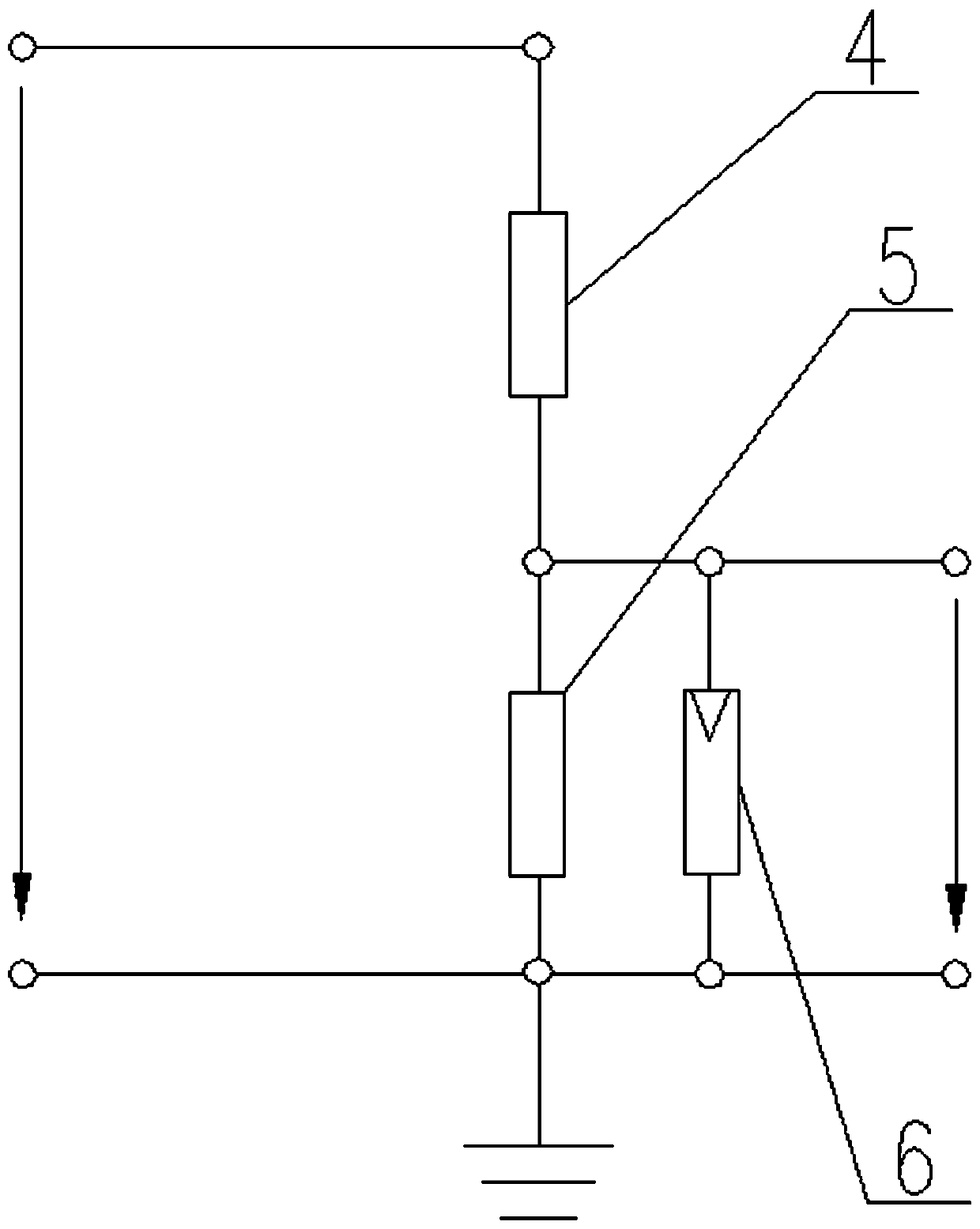

[0013] figure 1 , 2 As shown: an insulating plug with sensing function includes epoxy resin casting body 1, metal shielding case 2, high voltage terminal 3, high voltage resistor 4, low voltage resistor 5, varistor 6, outer hexagonal boss 7, Waterproof joint 8. The high-voltage terminal 3, the high-voltage resistor 4, the low-voltage resistor 5, and the varistor 6 are integrally molded through the epoxy resin casting body 1. The high-voltage terminal 3 is set at the upper conical insertion end of the epoxy resin casting body 1. The high-voltage resistor 4 and the low-voltage resistor 5 are connected to the waterproof joint 8 on the lower surface of the epoxy resin cast body, the low-voltage resistor 5 is connected in parallel with the varistor 6, and the lower part of the epoxy resin cast body 1 is encapsulated in the metal shielding case 2, and the metal shielding case 2 The center o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap