Electronic chip welding device

A welding device, electronic chip technology, applied in auxiliary devices, welding equipment, printed circuits, etc., can solve the problems of different welding materials selection of different temperatures, unreasonable materials, low work efficiency, etc., to improve welding efficiency, Long service life and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The present invention will be further explained below in conjunction with the drawings:

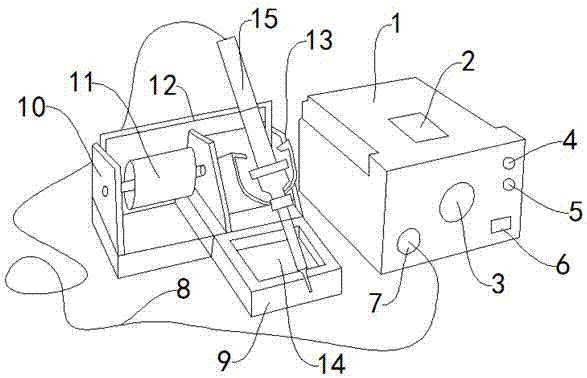

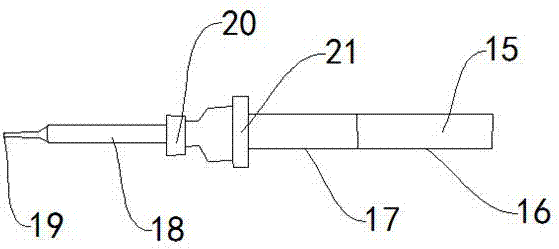

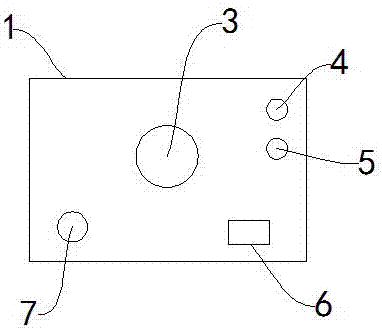

[0021] Such as Figure 1-Figure 3 As shown, an electronic chip soldering device includes a host 1, a tin wire 11, a soldering iron 15, a power lead 8, a high temperature resistant sponge 14, a soldering iron core 18, a soldering iron tip 19, and a clamp 20. The host 1 is provided with a host nameplate 2 There is a temperature adjustment knob 3 on the front of the host 1. The temperature adjustment knob 3 is used to adjust the temperature when welding different materials. One side of the temperature adjustment knob 3 is provided with a soldering iron socket 7, which is used to connect the power lead 8, and the temperature adjustment knob 3 There is a power indicator light 4 at the other end, a heating indicator light 5 is provided under the power indicator light 4, a switch button 6 is provided under the heating indicator light 5, a soldering iron base 9 is provided next to the host 1, an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap