Vehicle body jointing part sealing structure and preparation thereof, vehicle body side wall lower beam and vehicle

A technology for sealing structures and components, applied in the field of vehicles, can solve the problems of increasing the amount of material used for the side wall outer panel 4, unfavorable vehicle lightweight design, increasing logistics and installation rhythm, etc., to ensure the appearance quality, lightweight design, Connection for reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

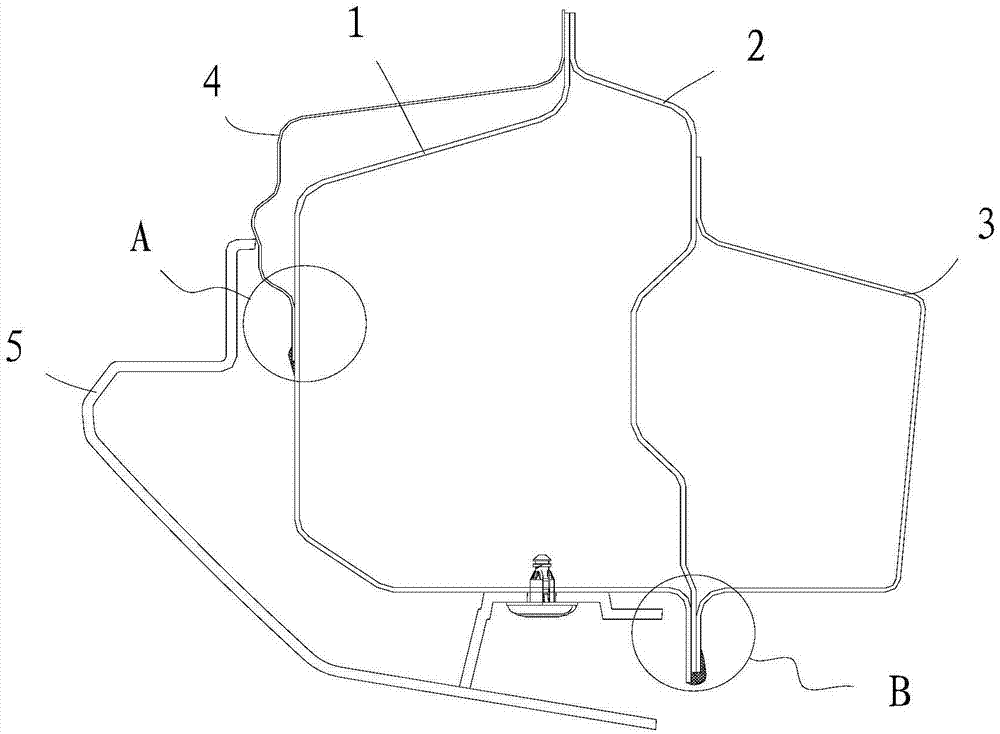

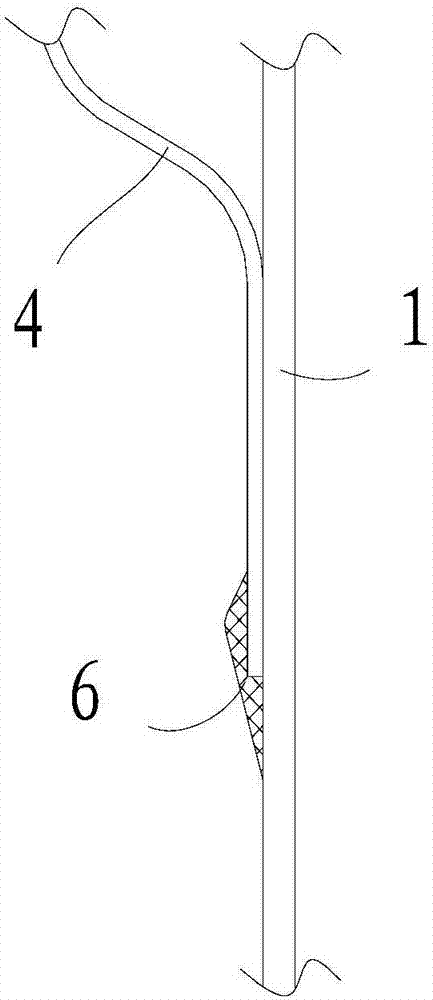

[0042] The invention relates to a sealing structure of a car body splicing part, which includes a first member, and a second member located outside the first member, which covers part of the first member and forms a solid connection with the first member, and also includes a second member formed on the first member The outer protrusion on the first member and located outside the covered area of the second member, in the recessed area between the outer protrusion and the second member, is filled with a seal that covers the fixed part of the first member and the second member glue.

[0043] In the sealing structure of the splicing part of the vehicle body, an outer protrusion is provided on the first member, and a recessed area including the fastening position of the first member and the second member is formed between the outer protrusion and the second member, and the sealant is filled in the recess In the region, the sealing glue surface and the exposed end surface of the firs

Embodiment 2

[0053] This embodiment relates to a side sill of a vehicle body, and its structure can still be as follows Image 6 As shown, the side sill of the vehicle body includes a sill inner panel 2, a floor side sill 3 welded to the sill inner panel 2, and a body splicing part sealing structure as in the embodiment is fixedly connected to the sill inner panel 2, and as shown in FIG. In the description of Embodiment 1, the first member is the door sill reinforcement plate 1 that forms a solid connection with the door sill inner panel 2, the second member is the side wall outer panel 4, and the door sill reinforcement plate 1 and the side of the floor The beams 3 also respectively extend toward the inner panel 2 of the threshold, and are converging and fixedly connected to both sides of the inner panel 2 of the threshold.

[0054] The side sill of the vehicle body in this embodiment adopts the sealing structure of the splicing parts of the vehicle body in Embodiment 1, so that the appearan

Embodiment 3

[0056] This embodiment relates to a vehicle on which the side sill of the vehicle body as described in the second embodiment is assembled. The vehicle of this embodiment can ensure the appearance quality of the side sill of the vehicle body, and there is no need to design the side sill guard plate to cover the sealant at the weld between the inner panel of the sill, the outer panel of the side panel and the reinforcement plate of the sill. At the same time, It can also reduce the amount of side panels used to achieve a lightweight design of the vehicle body.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap