Buffering device for removal in inverted state used in conveying of glass-bottled milk production line

A buffer device and glass bottle technology, which is applied in packaging, packaging bottles, transportation and packaging, etc., can solve the problems of affecting product appearance, scratching glass bottles, and glass bottles being thin, so as to ensure the appearance, prevent scratches, and guarantee beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

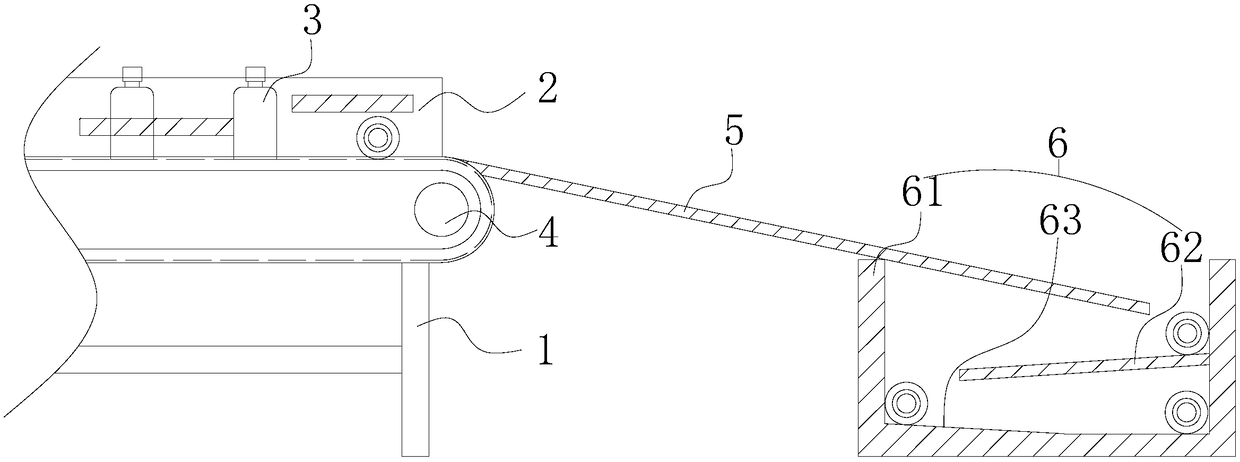

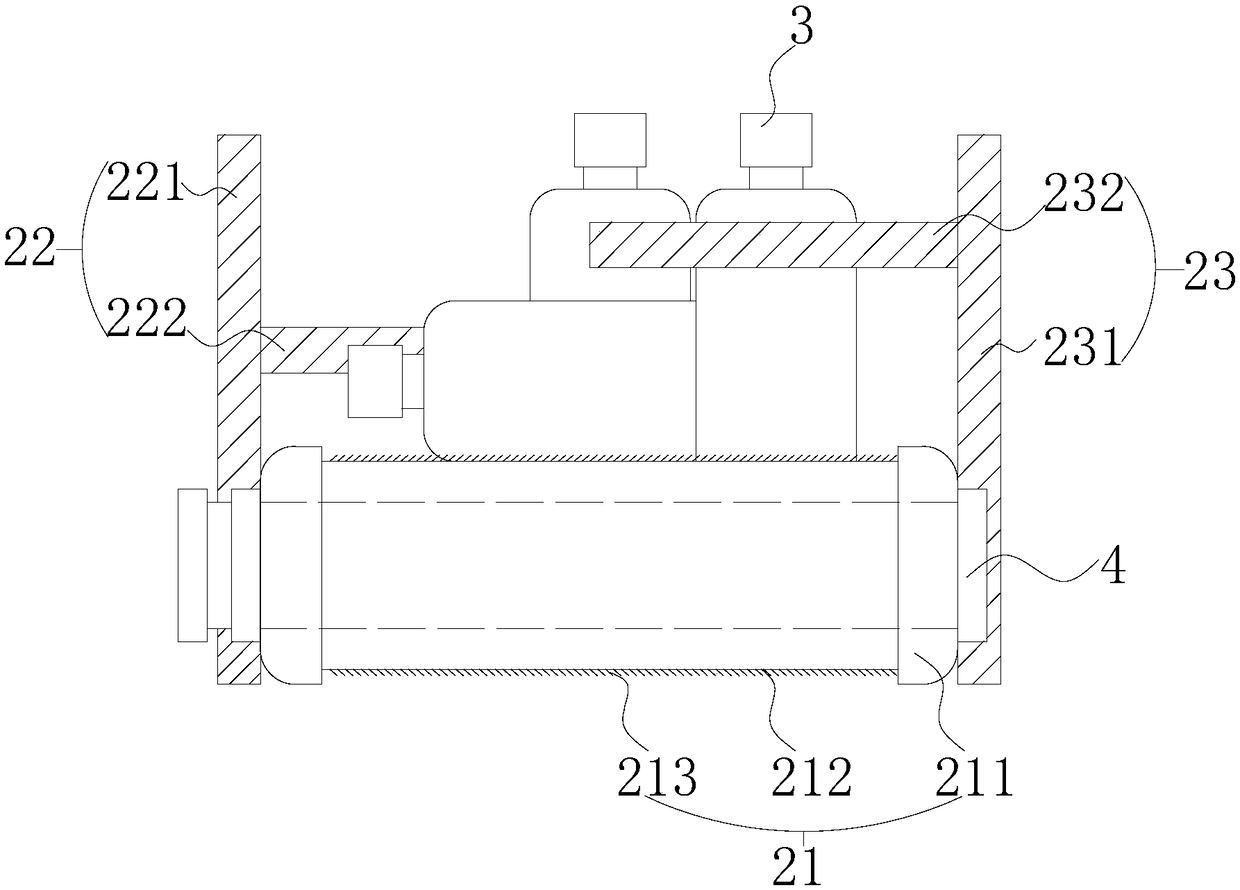

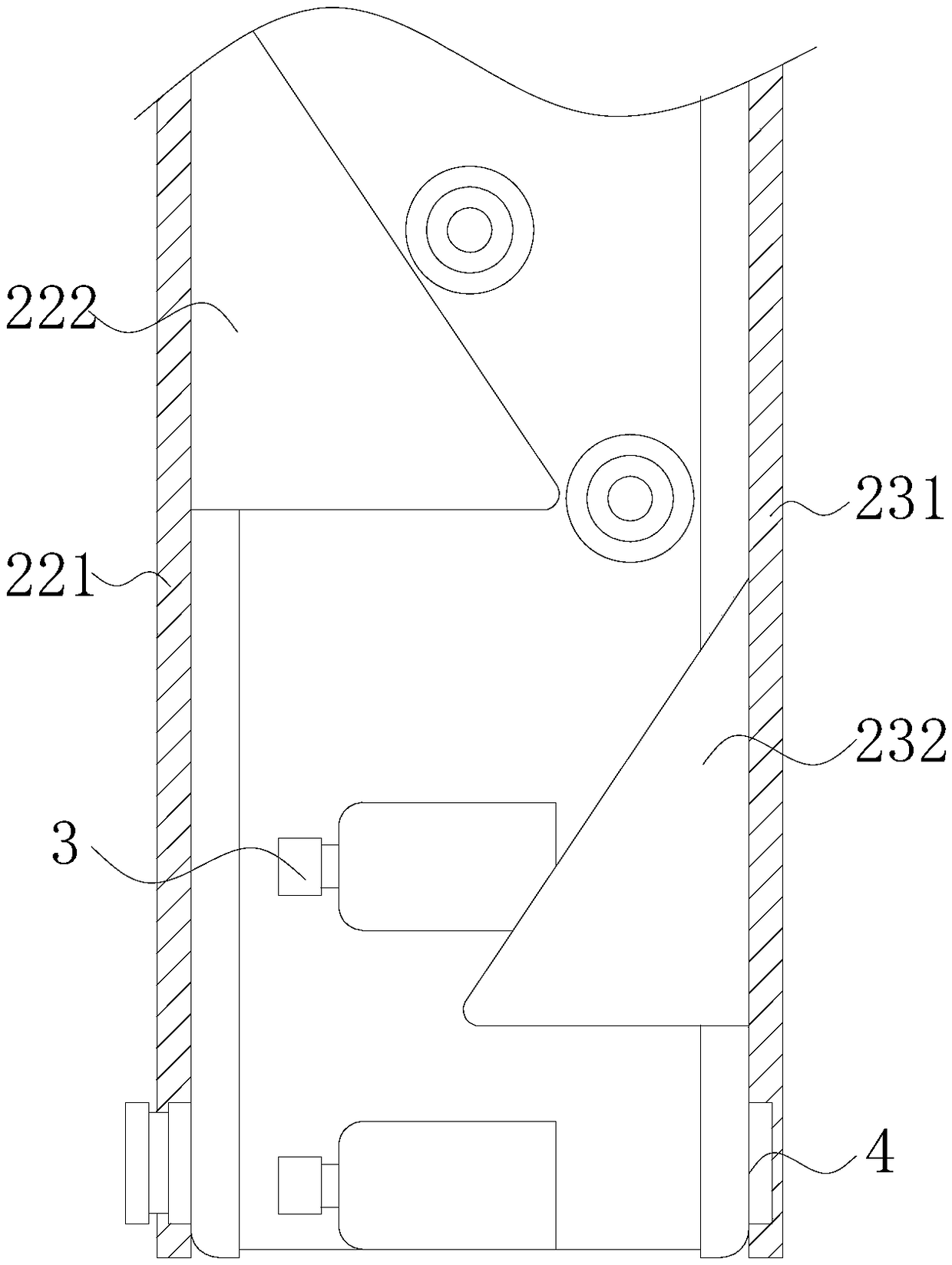

[0026] Such as Figure 1-Figure 3 As shown, the present invention provides a technical solution of a buffer device that is dumped off the shelf for conveying a glass bottled milk production line:

[0027] A buffer device for the delivery of a glass bottle milk production line in an inverted shape, and its structure includes a supporting frame 1, a stable tilting mechanism 2, a milk glass bottle 3, a transmission rotating shaft 4, a lower rack inclined plate 5, and reciprocating loading Box 6, the supporting frame 1 is arranged under the stable tilting mechanism 2 and connected vertically by electric welding, the milk glass bottles 3 are evenly and equidistantly arranged above the stable tilting mechanism 2, the transmission rotating shaft 4 It is arranged in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap