Intelligent transportation packaging box for composite materials

A composite material and packaging box technology, applied in transportation and packaging, packaging, packaging recycling, etc., can solve the problems of low seismic capacity, poor sealing effect, poor sealing performance, etc., and achieve high practicability, remarkable progress, and improved sealing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

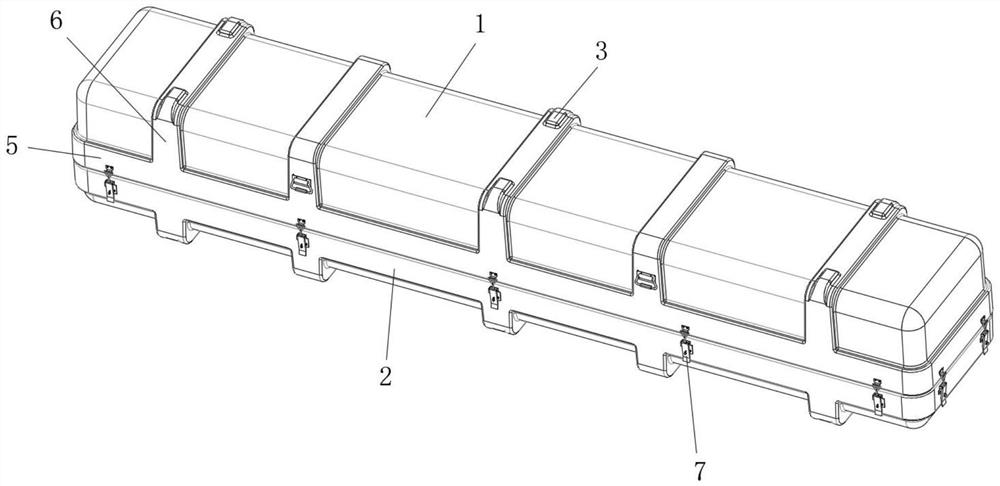

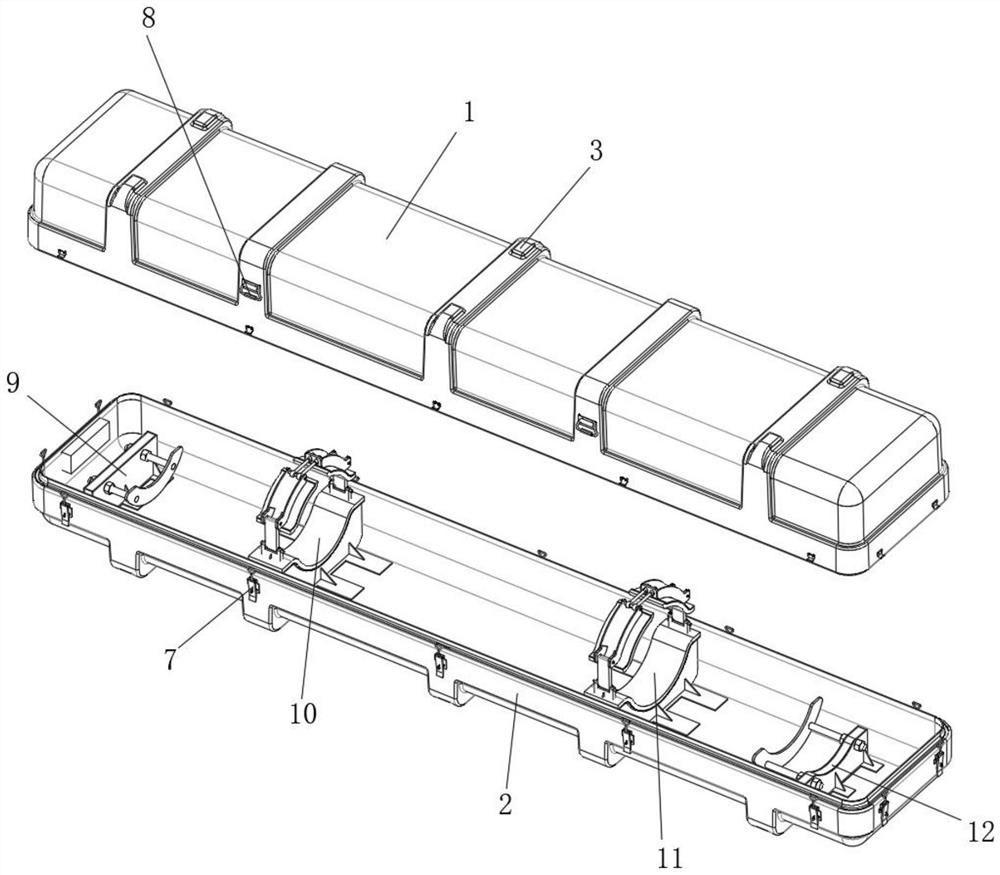

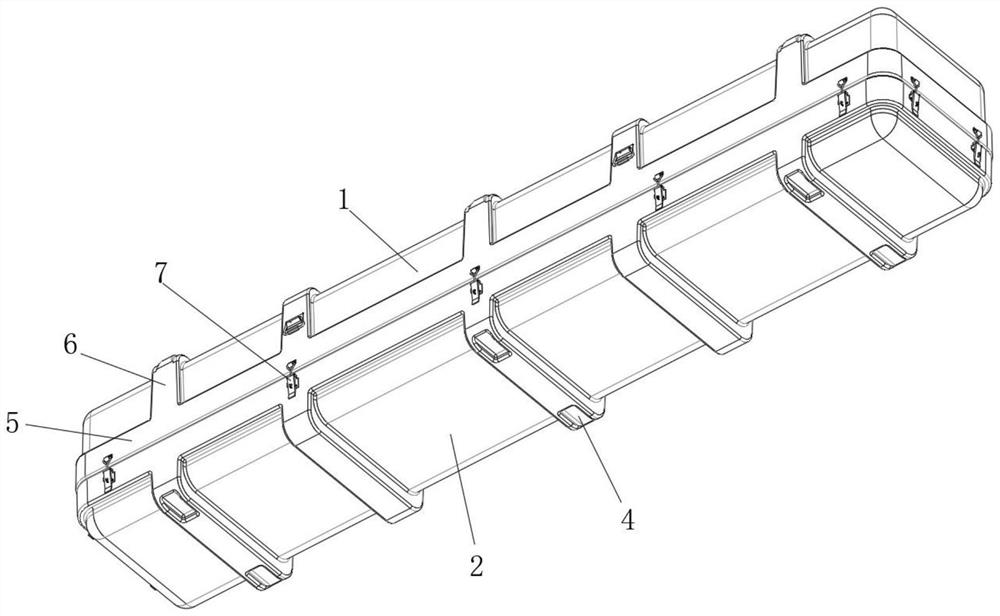

[0031] see Figure 1-5 , the present invention provides a technical solution: a composite material intelligent transportation packaging box, including an upper box 1, a lower box 2 is arranged at the bottom end of the upper box 1, and a front limit bracket 9 and a rear limit bracket 9 are arranged inside the lower box 2. Position bracket 12 , front locking bracket 10 , rear locking bracket 11 , a cover guide structure 13 is installed on the surface of the lower box 2 , a sealing strip 14 is fixed on the inner side of the cover guide structure 13 , and the material of the sealing strip 14 is Foam rubber or natural rubber, the sealing effect of the sealing strip 14 made of foam rubber or natural rubber is more excellent, spring shock absorbers 16 are installed between the bottom surface of the front locking bracket 10 and the rear locking bracket 11 and the inner wall of the lower box 2 , the spring shock absorber 16 can effectively protect the tight equipment through its own de...

Embodiment 2

[0034] see Image 6 , the upper box 1 and the lower box 2 are provided with a data acquisition system, and the data acquisition system includes:

[0035] Sensors are used to monitor and record the transportation status of the packing box in real time, mainly through pressure sensors, temperature and humidity sensors, vibration sensors, counters and speed sensors for detailed records;

[0036] The liquid crystal display module, connected with the sensor, is used to display the value recorded by the sensor;

[0037] Threshold alarm module, connected with the host computer and the sensor, used to monitor the current sensor value, if the threshold is exceeded, an alarm will be issued;

[0038] The monitoring center is used to monitor the abnormal situation of the packing box in the cloud. For example, when the sensor parameters are abnormal, the staff can be notified in time for disposal;

[0039] The owner's client terminal is provided for the owner or customer to use, so that ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap