Mechanical drive-type seismic experience platform

A mechanical drive and platform technology, applied in simulators, instruments, aerospace equipment, etc., can solve the problems of slow oil cylinder movement, low vibration frequency of the platform, and low authenticity of earthquake experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

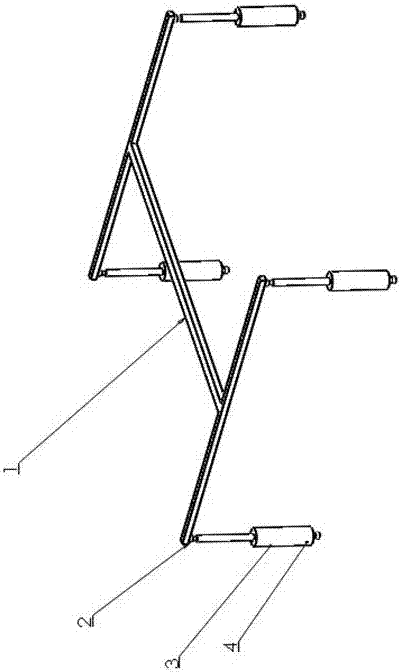

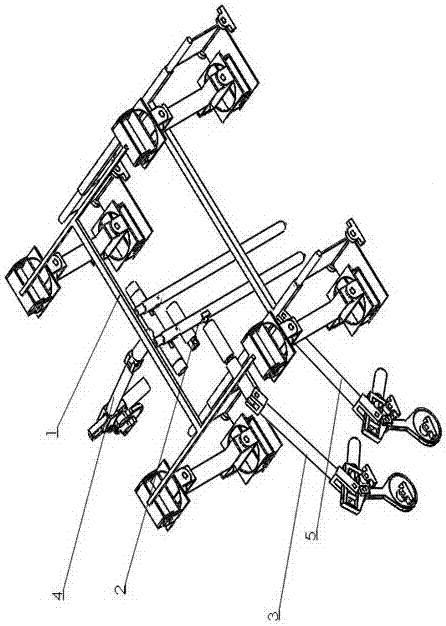

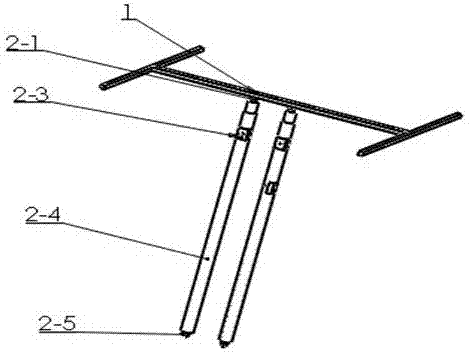

[0008] as attached image 3 As shown, a platform top frame 1, the middle part of the platform top frame 1 is equipped with two identical center columns 2, the upper part of the center column 2 is an upper ball hinge 2-1, and the upper ball hinge 2-1 is connected to the telescopic column 2-2, and the telescopic The outside of the column 2-2 is a sleeve 2-4, the upper side of the sleeve 2-4 is connected to the Y-direction connecting plate 2-3, the lower part of the sleeve 2-4 is connected to the lower ball joint 2-5, and the lower ball joint 2-5 is installed on the On the foundation, the middle and lower side of the front central column 2 is connected to the X-direction connecting plate 3-1. as attached Figure 4 As shown, the X-direction connecting plate 3-1 is connected to the swing rod 3-2, the swing rod 3-2 is connected to the X-direction push rod 3-3, and the X-direction push rod 3-3 is connected to the X-direction vibration source 3-4. as attached Figure 5 Shown is the di

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap