Flushing structure, water purifier and flushing method

A technology for water purification and concentrated water, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of waste water discharge, prolonging service life and improving water production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

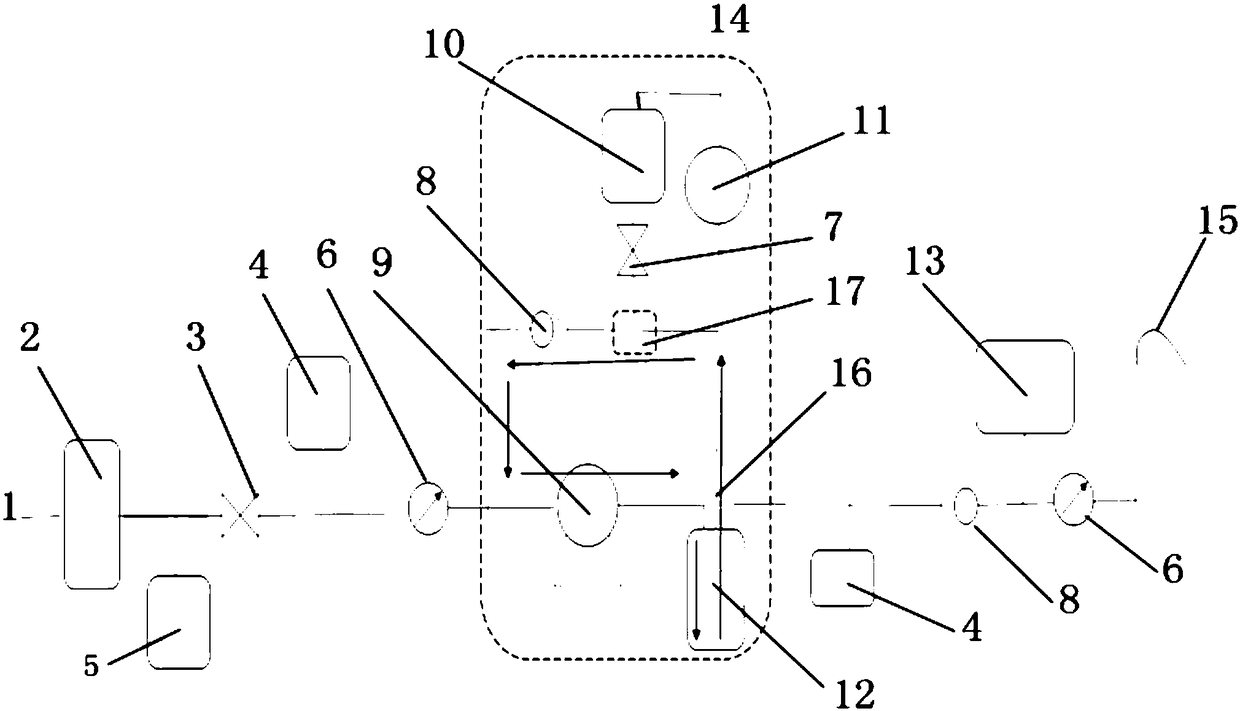

[0028] Such as figure 1 As shown, the flushing structure of the present invention includes a high-pressure pump, a reverse osmosis filter element, a first solenoid valve, and a second solenoid valve; the water inlet of the high-pressure pump communicates with the first solenoid valve; the water outlet of the high-pressure pump communicates with the reverse The water inlet of the osmosis filter element is connected; the water outlet of the reverse osmosis filter element includes a concentrated water outlet and a clean water outlet; the concentrated water outlet of the reverse osmosis filter element is connected with the water inlet of the high-pressure pump to form a loop; A Venturi tube is provided in the circuit part where the concentrated water outlet of the permeation filter element is connected to the water inlet of the high-pressure pump; the Venturi tube includes a water inlet and a water outlet, and a cleaning agent inlet is arranged between the water inlet and the water ou

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap