Multithread screwed changeable heel device

A technology of multi-thread thread and locking device, which is applied in the direction of shoe heel, heel pad, clothing, etc., can solve the problem that the heel clip seat and the sole clip seat cannot cooperate, the clipping bump has a large binding force, and the patent cannot be used. Implementation and other issues to achieve the effect of increasing the safety factor and service life, increasing safety, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

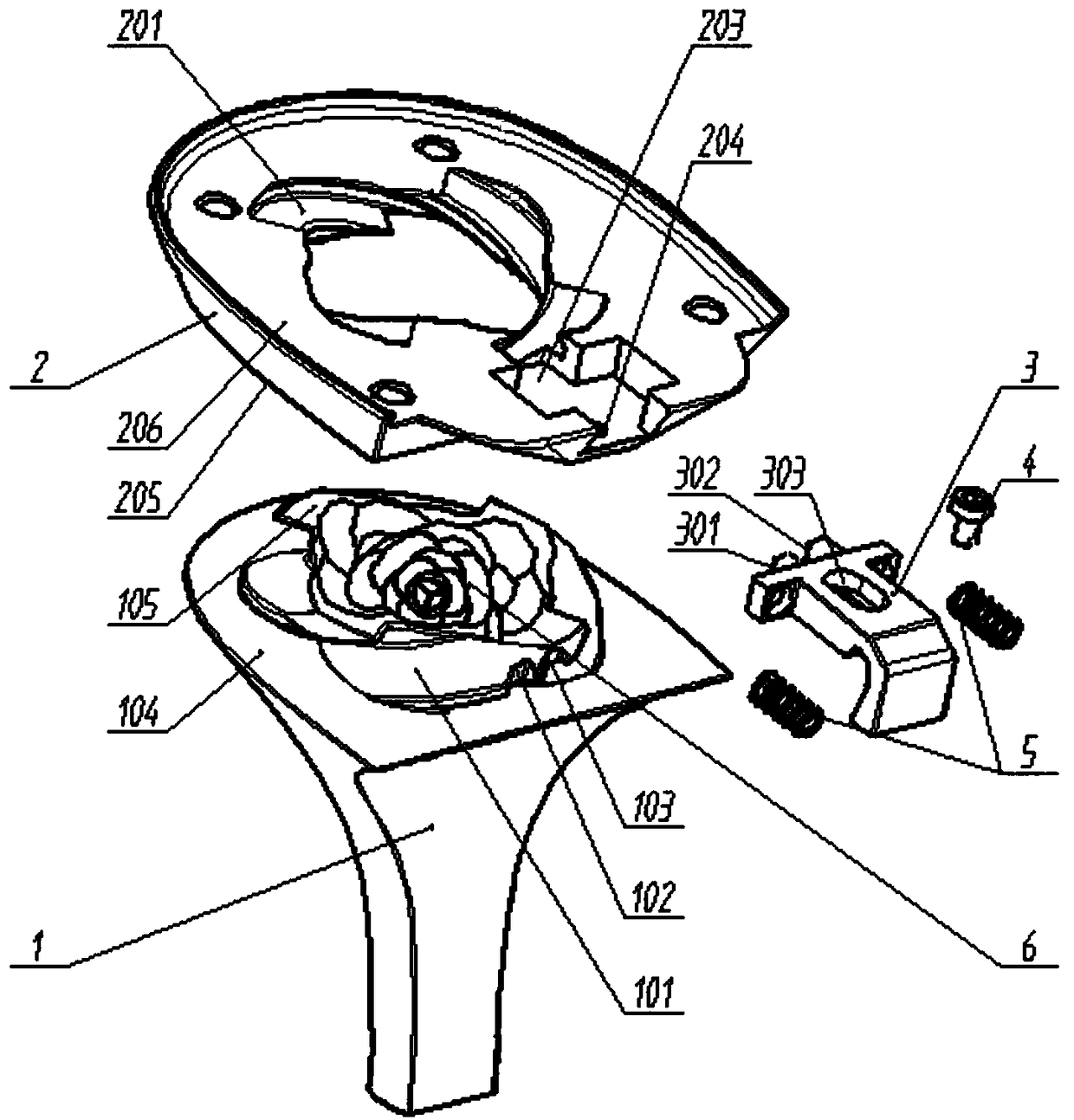

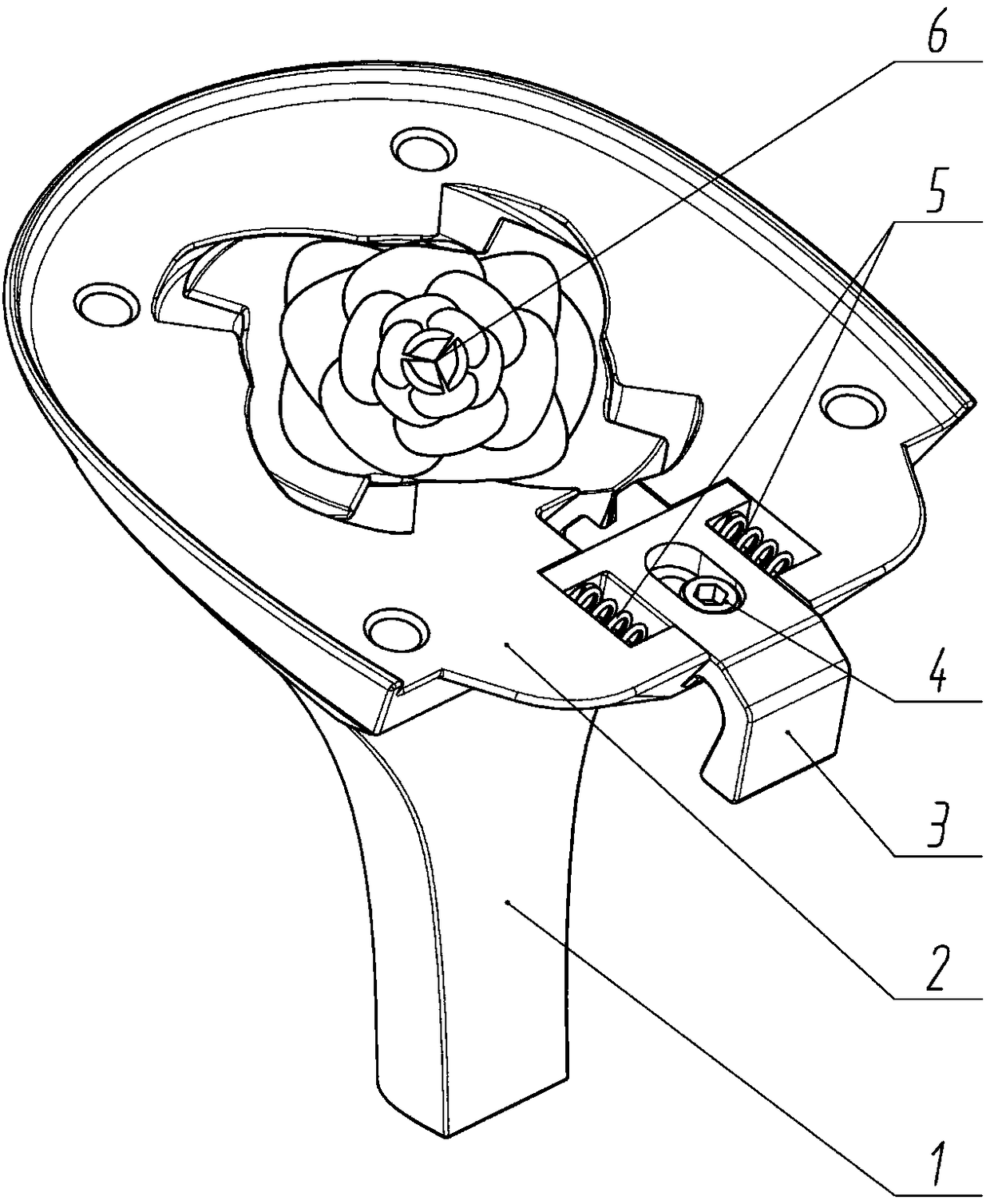

[0027] The invention discloses a multi-thread thread type replaceable heel device. The multi-thread thread type replaceable heel device is arranged at the joint between the heel 1 and the sole, and includes a multi-thread bolt 101 arranged on the heel 1 and a bolt set on the sole. The multi-thread nut 201 matched with the multi-thread bolt 101, the number of threads of the multi-thread bolt 101 and the multi-thread nut 201 is the same, at least two or more threads, separated and rotated by the rotation between the multi-thread bolt 101 and the multi-thread nut 201 Locking realizes the removal and connection of the heel. The multi-thread n is three to eight threads. The rotation angle of the multi-thread bolt 101 is 360 / 2n~360 / n degrees. . Or the multi-thread nut 201 can be penetrated and arranged on the receiving layer 2, and the receiving layer 2 is fixedly connected to the sole; the upper plane 105 of the multi-thread bolt is parallel to the upper plane 104 of the heel, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap