Extractor hood

The technology of a range hood and a casing is applied in the field of range hoods with sterilization and purification functions, and can solve the problems of limited sterilization and deodorization functions, uneven ozone concentration, affecting the effect of sterilization and purification, etc., and achieves good sterilization and deodorization treatment. Effect, effect of uniform ozone concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

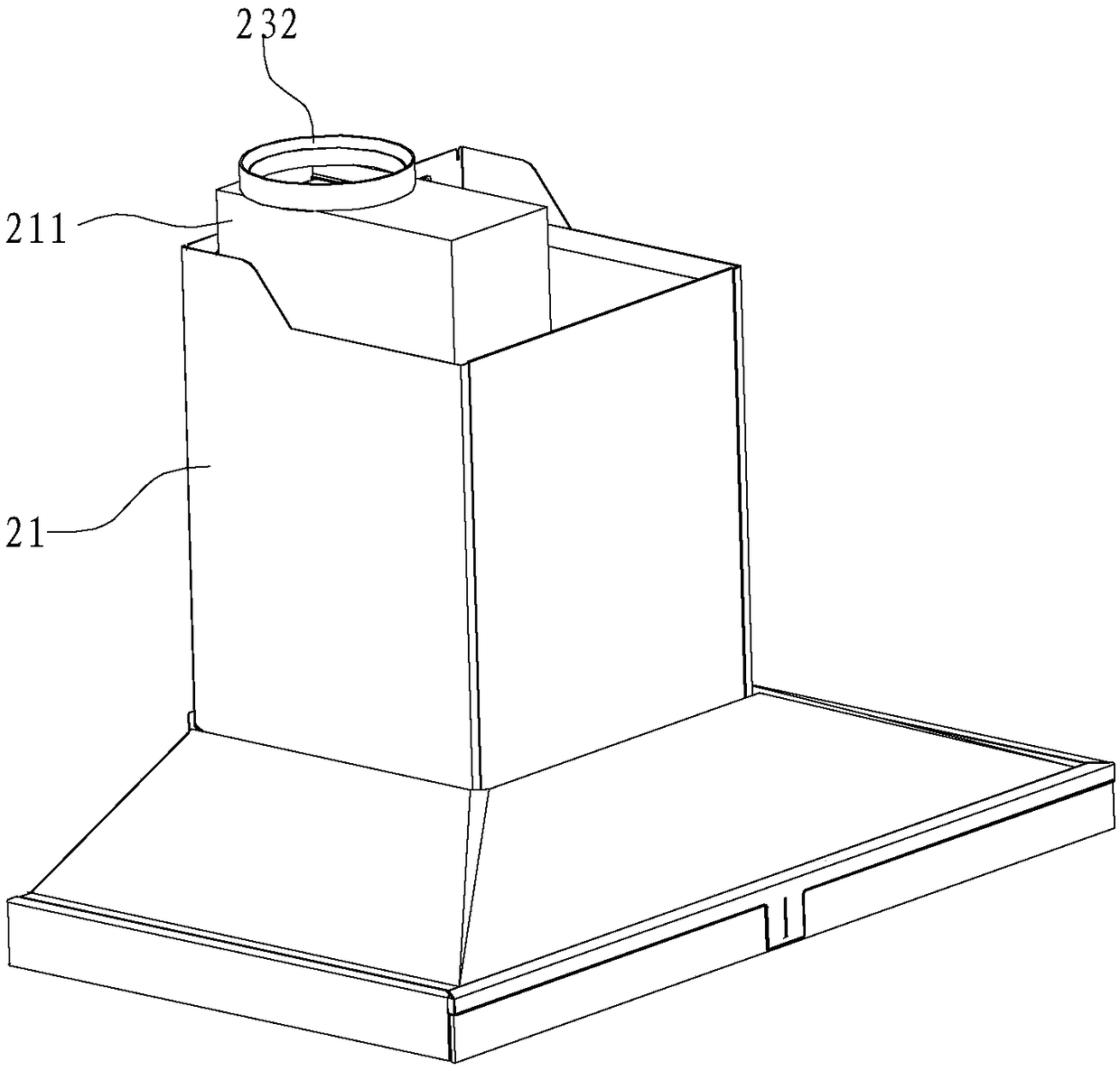

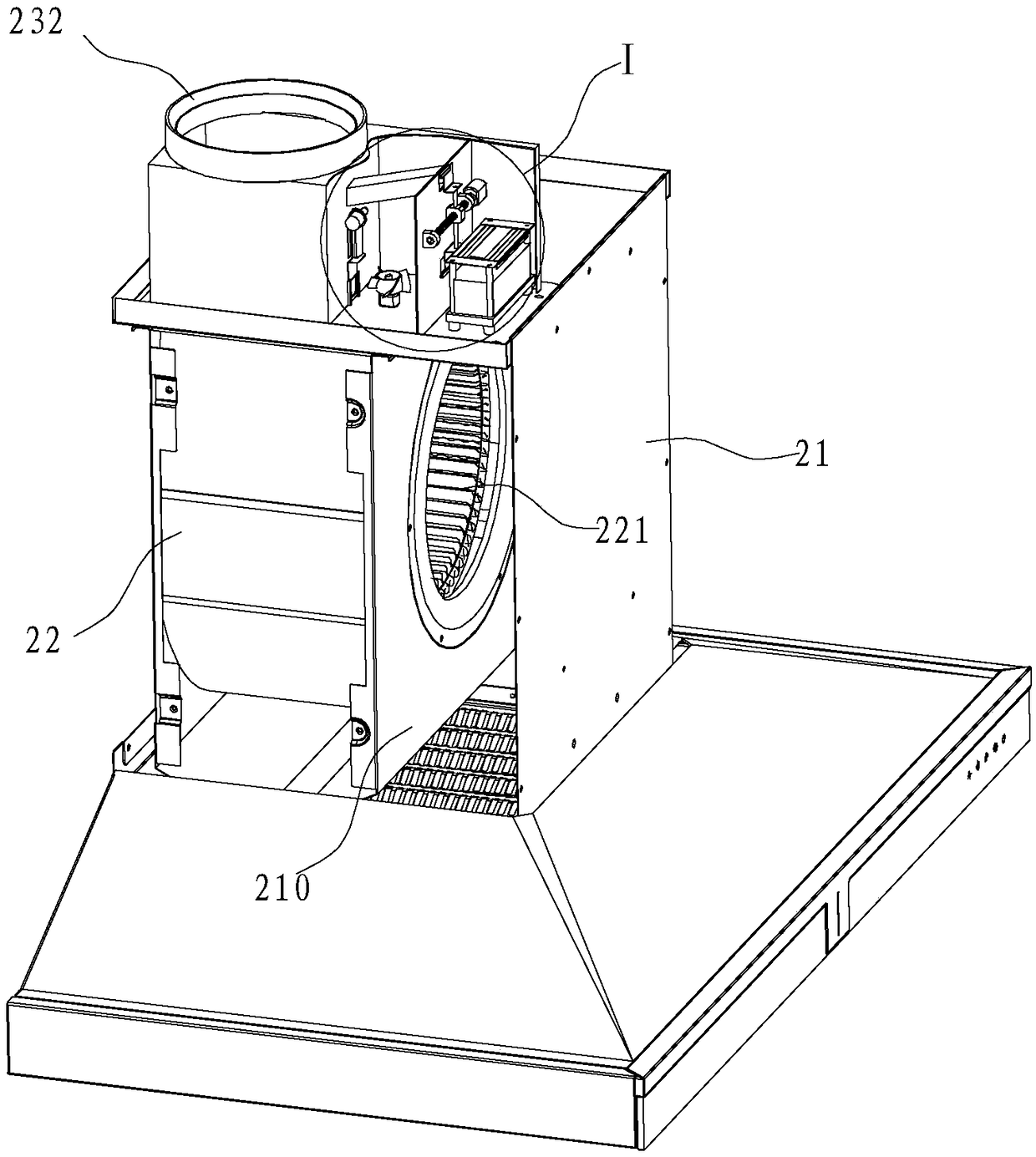

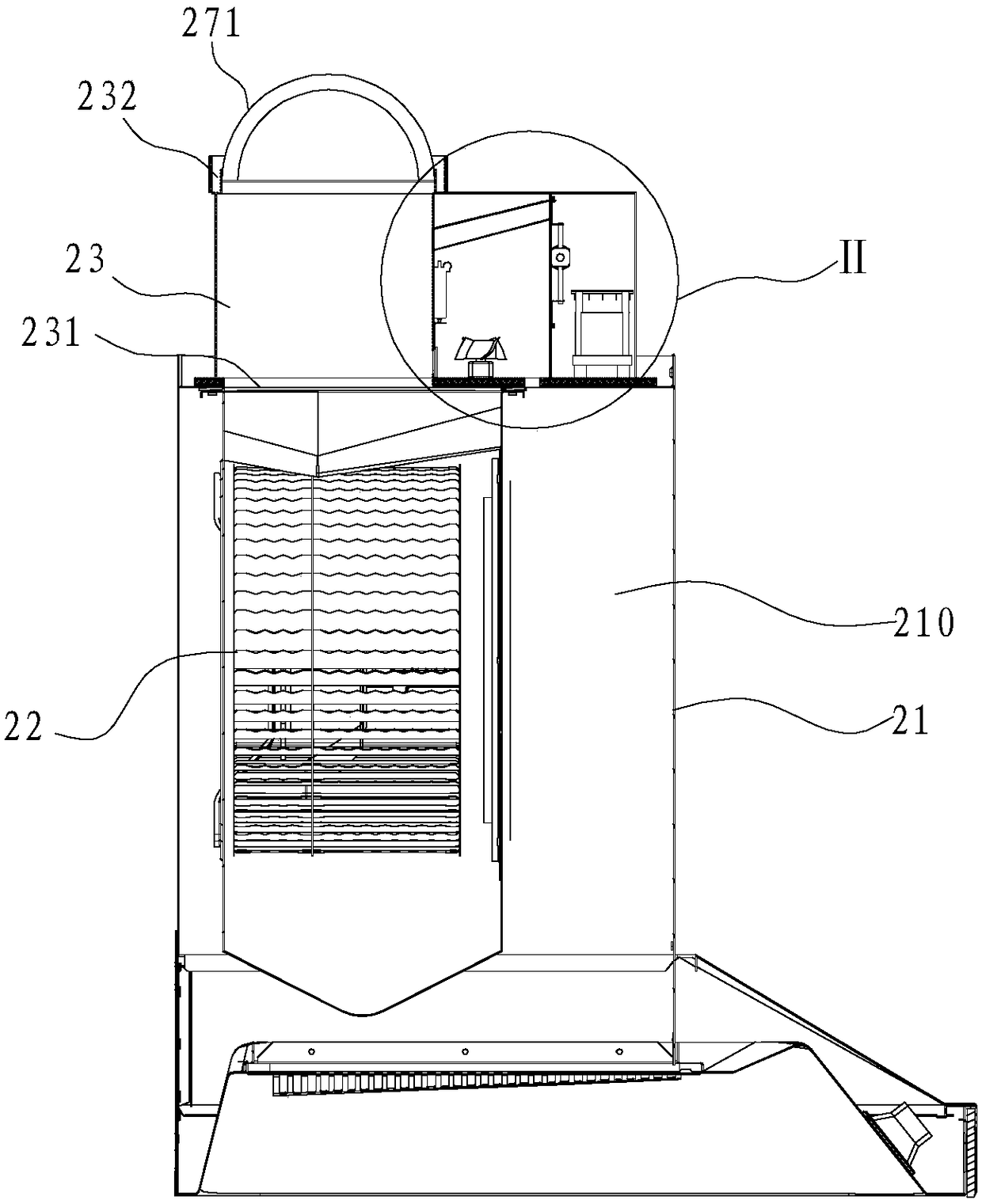

[0029] Such as Figure 1-7 As shown, a range hood includes a casing 21 with an inner cavity 210 and an air outlet cover 211, the inner cavity 210 is provided with a fan 22, the above air outlet cover 211 is provided with an air outlet cavity 23, and the outlet The air chamber 23 is located above the inner chamber 210 and communicates with the inner chamber 210 through the air inlet 231. The top of the air outlet chamber 23 has an air outlet 232, and the air outlet 232 is provided with an air outlet valve plate capable of opening and closing the air outlet 232. 271.

[0030] Further, the air outlet hood 211 is also provided with a clean chamber 24 and a mixing chamber 25 , the clean chamber 24 is provided with an ozone generator 26 , and the mixing chamber 25 is provided with a mixer 202 . Above-mentioned purification chamber 24 and mixing chamber 25 are communicated by gas outlet 242, and the ozone produced by ozone generator 26 is introduced into mixing chamber 25 through this

Embodiment 2

[0039] Such as Figure 8-10 As shown, the difference from Embodiment 1 is that in this embodiment, the above-mentioned air duct 28 is provided with a filter unit 280 inside the air duct 28 for filtering oil fume, and the filter unit 280 can filter the oil fume molecules in the air flow, thereby Avoid the soot molecules from polluting and damaging the ozone generator 26 . The filter unit 280 traverses in the air duct 28 and is arranged at intervals along the length direction of the air duct 28. Each filter unit 280 includes at least two filter bodies arranged at intervals along the width direction of the air duct 28. At least one end of each filter body is connected to the air duct 28. The inner wall of the air pipe 28 is fixed, and a filter channel 2800 for air flow is formed between adjacent filter bodies. Such a design can make the fume molecules entering the air duct 28 collide with the filter unit 280 smoothly, thereby better filtering the fume molecules. Further, the filte

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap