Tension stabilizing device and tension stabilization control method in horizontal floating mode

A stable control method and a stable device technology, applied in tension/pressure control, metal rolling, etc., can solve problems such as failure to meet precision requirements, and achieve the effect of wide tension adjustment range and high tension control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

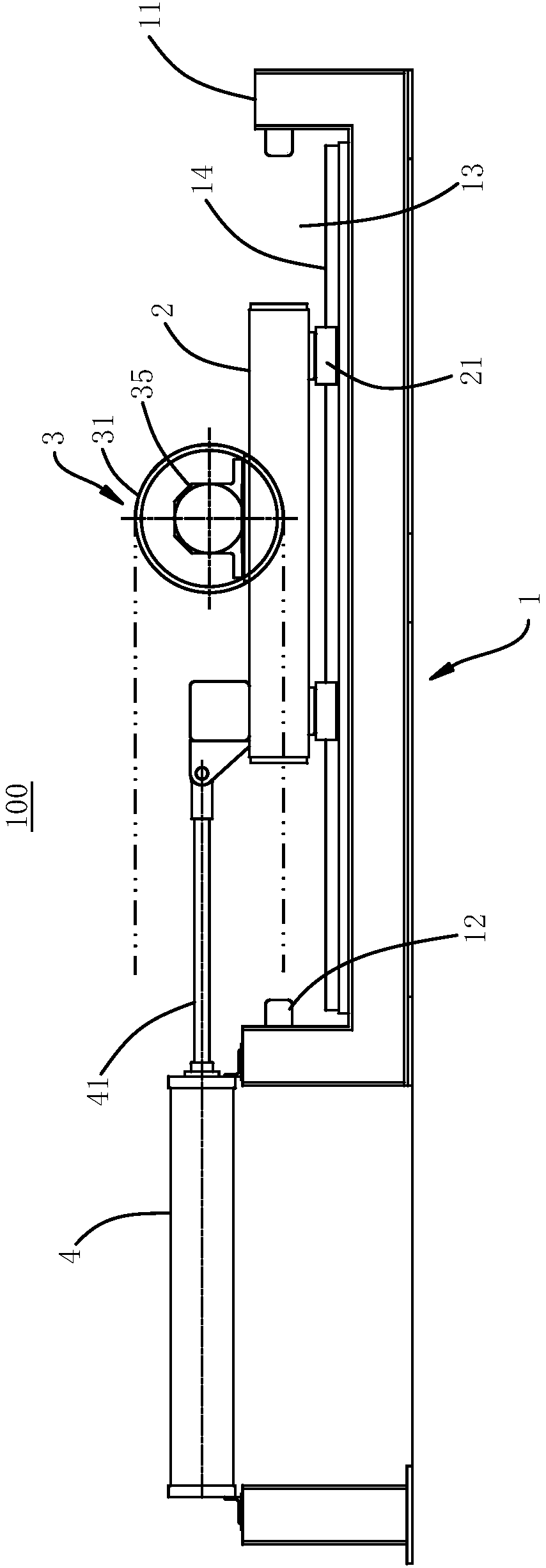

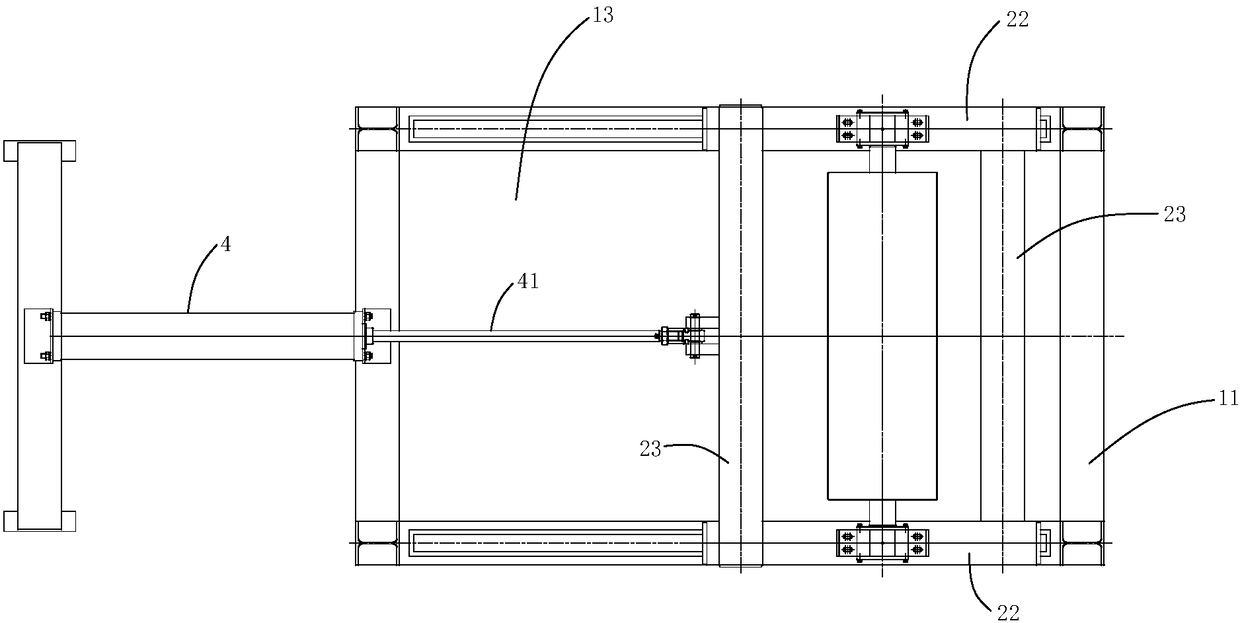

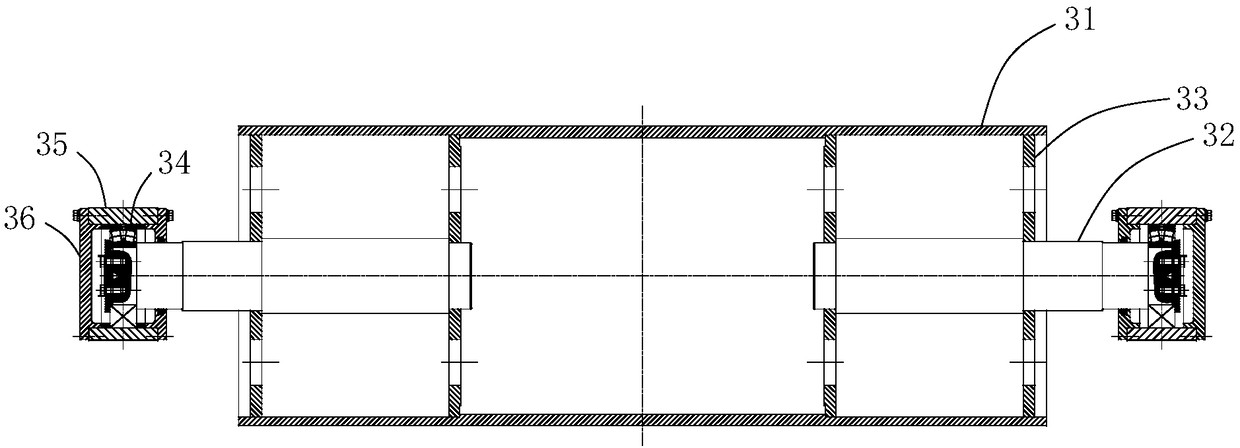

[0039] Please refer to figure 1 , this embodiment provides a horizontal floating tension stabilization device 100, which is applied between the tension roller 5 and the tension roller 6 in front of the furnace, and includes a fixed base 1, a floating base 2 located on the fixed base 1, and a The buffer roller 3 of the floating base 2, the driving assembly connected with the floating base 2, and the control assembly connected with the driving assembly.

[0040] Such as Figure 1-Figure 4 As shown, in this embodiment, the fixed base 1 is provided with a guide portion 14, and the guide portion 14 extends along the advancing direction of the steel strip, and the floating base 2 is provided with a connecting portion 21 that cooperates with the guide portion 14, and the connecting portion 21 is connected to the guide portion. part 14, so that the floating base 2 can move relative to the fixed base 1 on the fixed base 1 along the guide part 14; The output end of the output end is conn

no. 2 example

[0066] After research, the researchers found that the horizontal floating tension stabilization device 100 provided by the present invention, on the basis of the above-mentioned first embodiment, can also make the following optional other structural solutions, which are specifically described as follows:

[0067]The guide part 14 is a track, and the connecting part 21 includes at least four rollers. At least four rollers are distributed at both ends of the floating base 2 along the length direction of the guide part 14. The rollers are rotatably connected with the floating base 2, and the rollers are rotatably arranged. in the track.

[0068] The cooperation between the roller and the track improves the flexibility of movement of the floating base 2 and reduces the friction between the connecting part 21 and the guiding part 14 .

no. 3 example

[0070] After research, researchers have found that the horizontal floating tension stabilization device 100 provided by the present invention, on the basis of the above-mentioned first embodiment, can also make the following optional other structural solutions, which are specifically described as follows:

[0071] The guide part 14 is a rack, the connecting part 21 is a gear, the gear is rotatably connected to the floating base 2, and the gear and the rack mesh. The meshing of the gear and the rack improves the positioning accuracy of the connecting portion 21 and the guiding portion 14 and facilitates the movement of the floating base 2 relative to the fixed machine base 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap