Multifunctional homogenizer

A homogenizer and multi-functional technology, applied in the direction of instruments, scientific instruments, sampling, etc., can solve the problems of small amount of homogenate, difficulty in reaching the quantity, easy cracking of the bottom of the tube, etc., to ensure integrity and reduce experimental errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

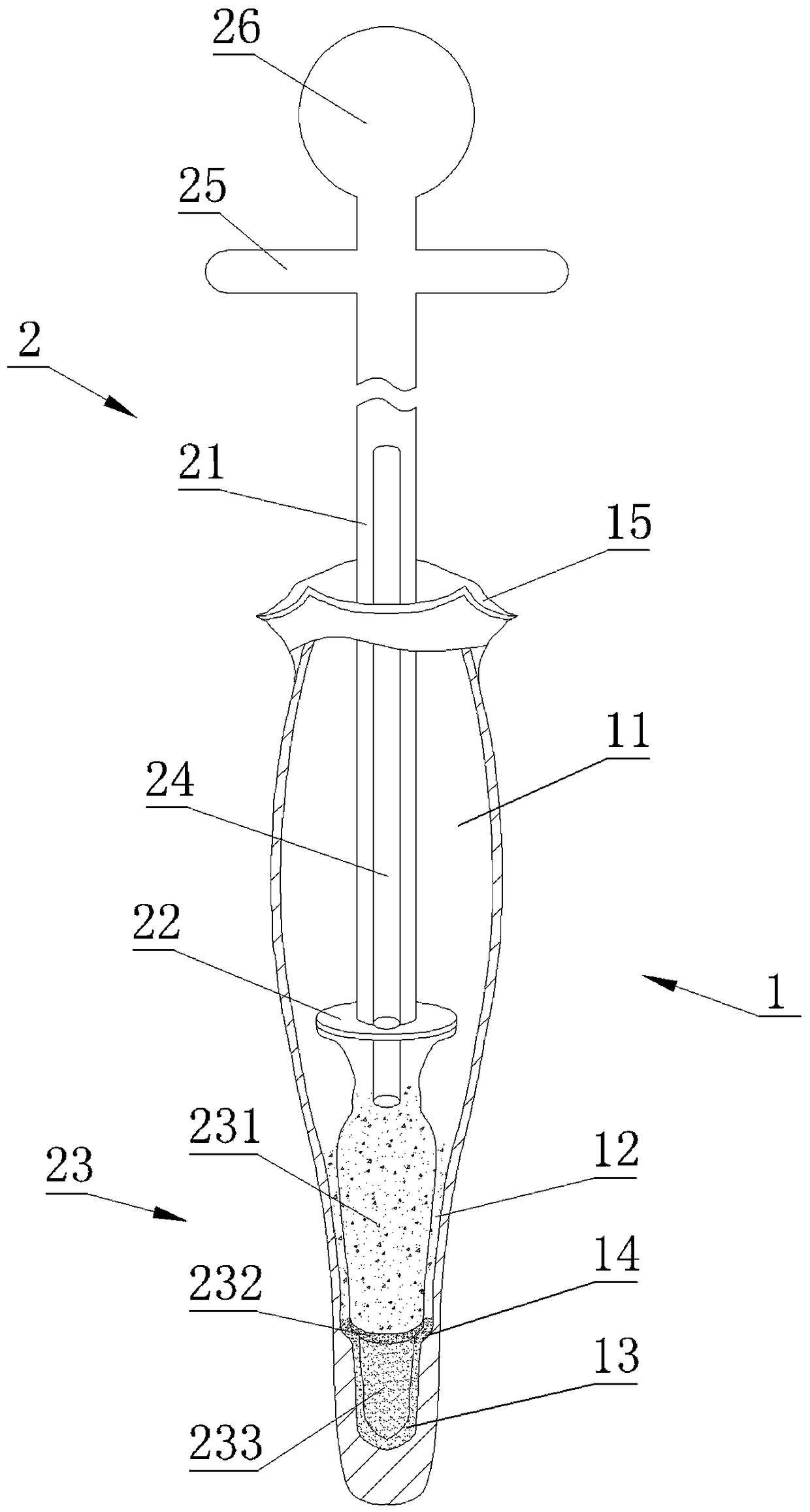

[0028] From figure 1 It can be seen that the multifunctional homogenizer of the present invention includes a homogenization tube 1 and a homogenization rod inserted in the homogenization tube 1, wherein,

[0029] The homogenization tube 1 is made of shatter-proof thickened glass material. The homogenization tube 1 includes an overflow prevention cavity 11, a rough grinding cavity 12, a fine grinding cavity 13, a rough grinding cavity 12 and a fine grinding cavity, which are arranged in communication with the upper part and the lower part. 13 are in the shape of a truncated cone with a large top and a small bottom. The axial length of the rough grinding cavity 12 is greater than that of the fine grinding cavity 13. A coarse and fine mixing positioning table 14 is provided between the rough grinding cavity 12 and the fine grinding cavity 13. The top opening of the anti-overflow cavity 11 is provided with two symmetrical outturned diversion ports 15. The anti-overflow cavity 11 is in t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap