Rotating shaft braking device

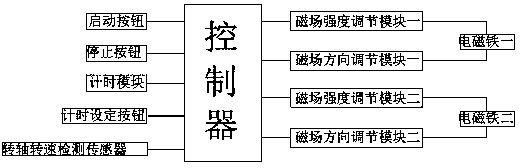

A brake device and shaft technology, applied in the direction of brake types, drum brakes, gear transmission mechanisms, etc., can solve the problems of shaft braking, untimely response of operators, misoperation, etc., to facilitate rapid braking and avoid artificial The effect of misoperation and high response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

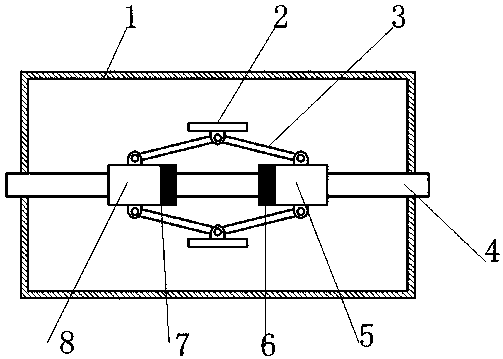

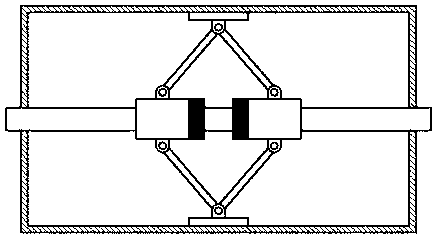

[0028] A rotating shaft braking device, which includes a braking cylinder 1, a rotating shaft 4 and a centrifugal mechanism; the rotating shaft 4 is inserted into the braking cylinder 1 and penetrates both ends of the braking cylinder 1, and the rotating shaft 4 is rotatably arranged on the braking cylinder 1; the centrifugal mechanism is rotatably arranged in the brake cylinder 1 and sleeved on the rotating shaft 4; the centrifugal mechanism includes a slider 1 5, a slider 2 8 and a number of friction blocks 2; the slider 1 5 The slider 2 is slidably sleeved on the rotating shaft 4 and moves along the axial direction of the rotating shaft 4; the top of each friction block 2 is used to contact the inner wall of the brake cylinder 1, and the bottom of each friction block 2 is hinged with two connecting The rod 3 and the two connecting rods 3 are hinged with the slider one 5 and the slider two 8 respectively;

[0029] like figure 1 and 2 As shown, the upper ends of the two connec

Embodiment 2

[0040] This embodiment is basically the same as the first embodiment, the difference is that the spherical surface of the ball 9 is in point contact with the inner wall of the groove 10 . like Figure 5As shown, the cross-section of the shaft section where the slider is installed is "cross"-shaped; the cross-sectional shape of the groove 10 is "V"-shaped, and the balls 9 are in point contact with both sides of the "V" shape; The point contact with the inner wall of the groove 10 can reduce the friction between the ball 9 and the groove 10 , which is more favorable for the slider to move on the groove 10 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap