Intertidal zone sediment incipient motion measuring device and method

It is a technology of sediment starting and measuring device, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc. It can solve the problems of small shear stress at the bottom and cannot reach the on-site measurement, and achieve accurate measurement results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

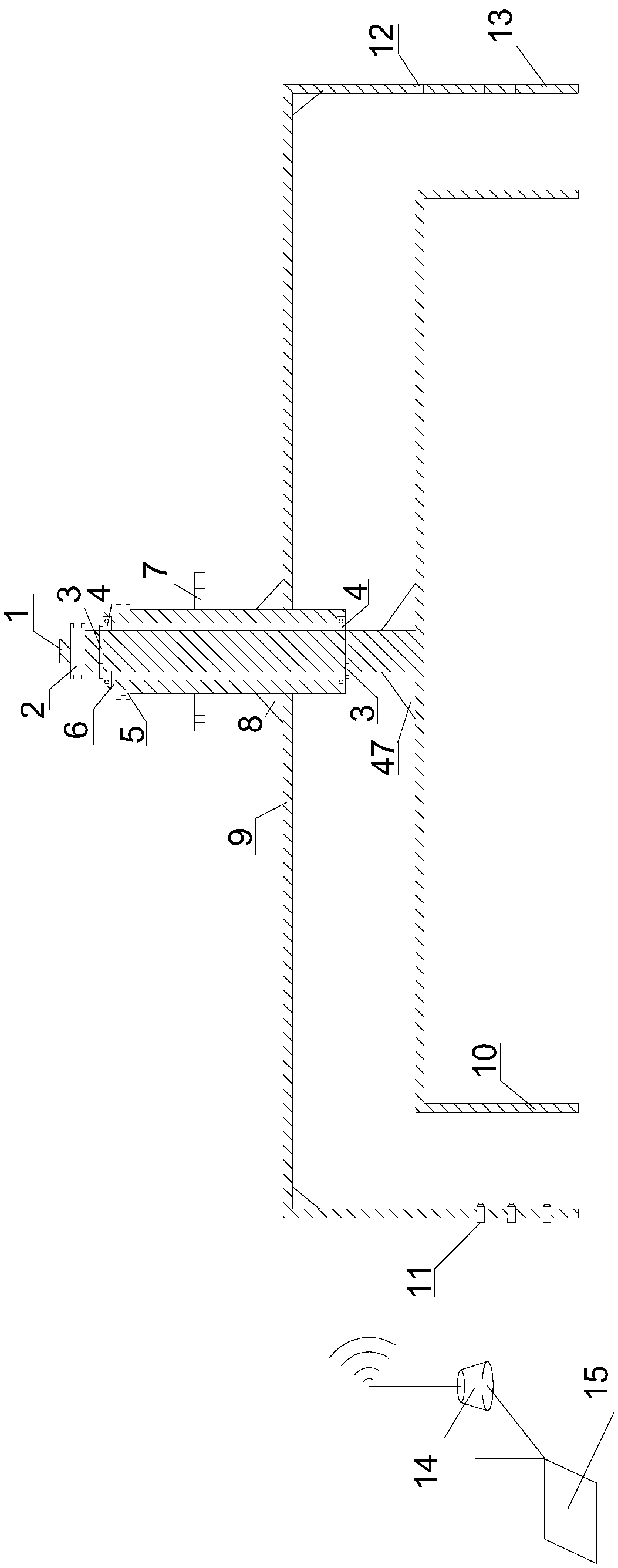

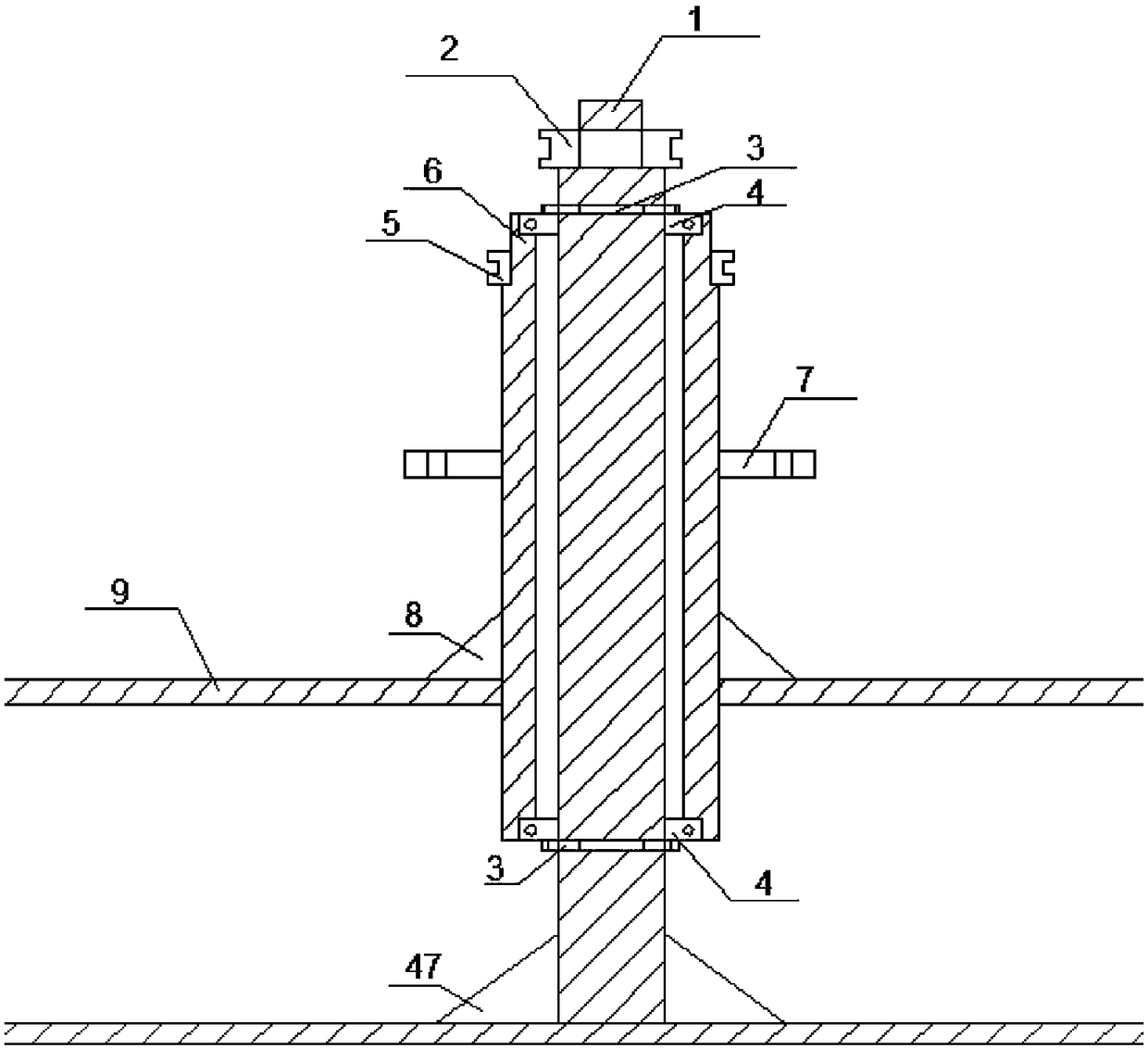

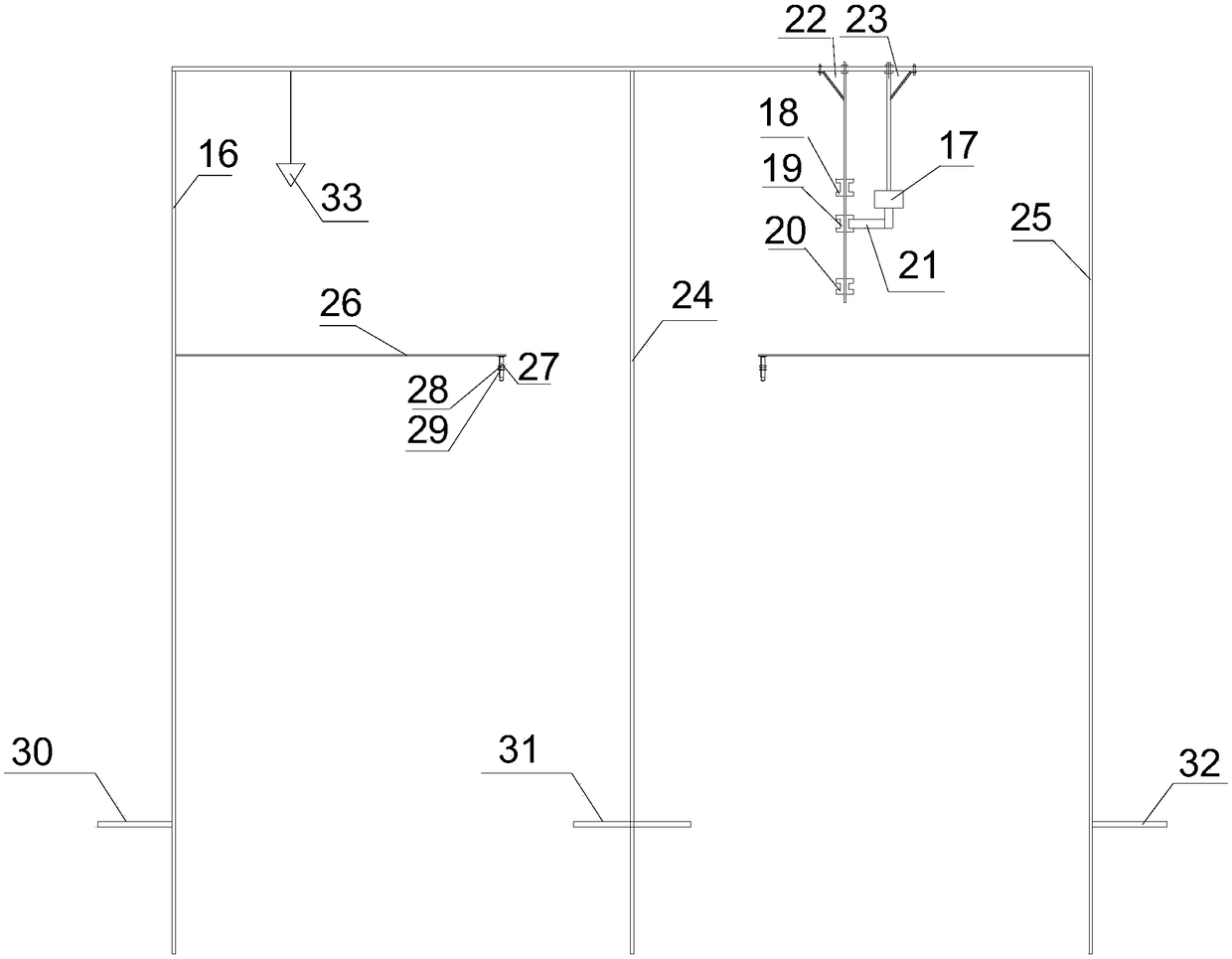

[0047] Such as figure 1 and 2 As shown, the upper structure of the device is mainly composed of a sleeve mandrel, an outer cylinder 9 made of plexiglass, and an inner cylinder 10 made of plexiglass. The sleeve mandrel includes an inner shaft 1 and an outer shaft 6, and the inner shaft 1 and the inner cylinder 10 is connected to each other through the first connecting rod 47 and the corner code, and the outer shaft 6 and the outer cylinder 9 are connected to each other through the second connecting rod 8 and the corner code; the inner shaft 1 and the outer shaft 6 are connected through the bearing 4, and the bearing 4 The outer side is clamped by the nut 3 to limit the movement of the bearing, and at the same time reduce the shaking of the shaft during rotation. The inner shaft 1 and the outer shaft 6 are respectively installed with the inner shaft pulley 2, the outer shaft pulley 5, and the outer shaft 6 A bearing shell 7 is set on the top; an OBS turbidity sensor 11 is installe

Embodiment 2

[0063] Define the optimum rotational speed ratio: for the instrument of measuring the starting stress of sediment for the radius r of the inner cylinder and the radius R of the outer cylinder, the radius r of the inner disc is 46 1 , the inner radius R of the outer disc 45 1 , the speed of the inner cylinder is n1, and the speed of the outer cylinder is n2 in the same direction. When the speed ratio k=n1 / n2 is a certain value, the distance from the bottom to the axis is r 1 ~R 1 The shear stress distribution is the most uniform in the range (because the area close to the inner and outer cylinders is blocked), and the speed ratio at this time is the optimum speed ratio.

[0064] When the radius r of the inner cylinder is limited (200mm≤r≤500mm), the radius of the outer cylinder is R, and the water depth is H. x=R / r(1.3≤x≤1.9), y=H / r(0.3≤y≤1.3), this limitation is because the size of the device is small in this range, it is easy to use, and the best The optimal speed ratio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap