Soil-rock interface original sample torsional shear test device and method

A test device, the original technology, applied in the measurement device, using a stable torsion force to test the material strength, using a stable shear force to test the material strength and other directions, can solve the problems of shrinking stress and concentration of the shear plane of soil and rock Achieve the effect of overcoming the change of soil and rock shear area and stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

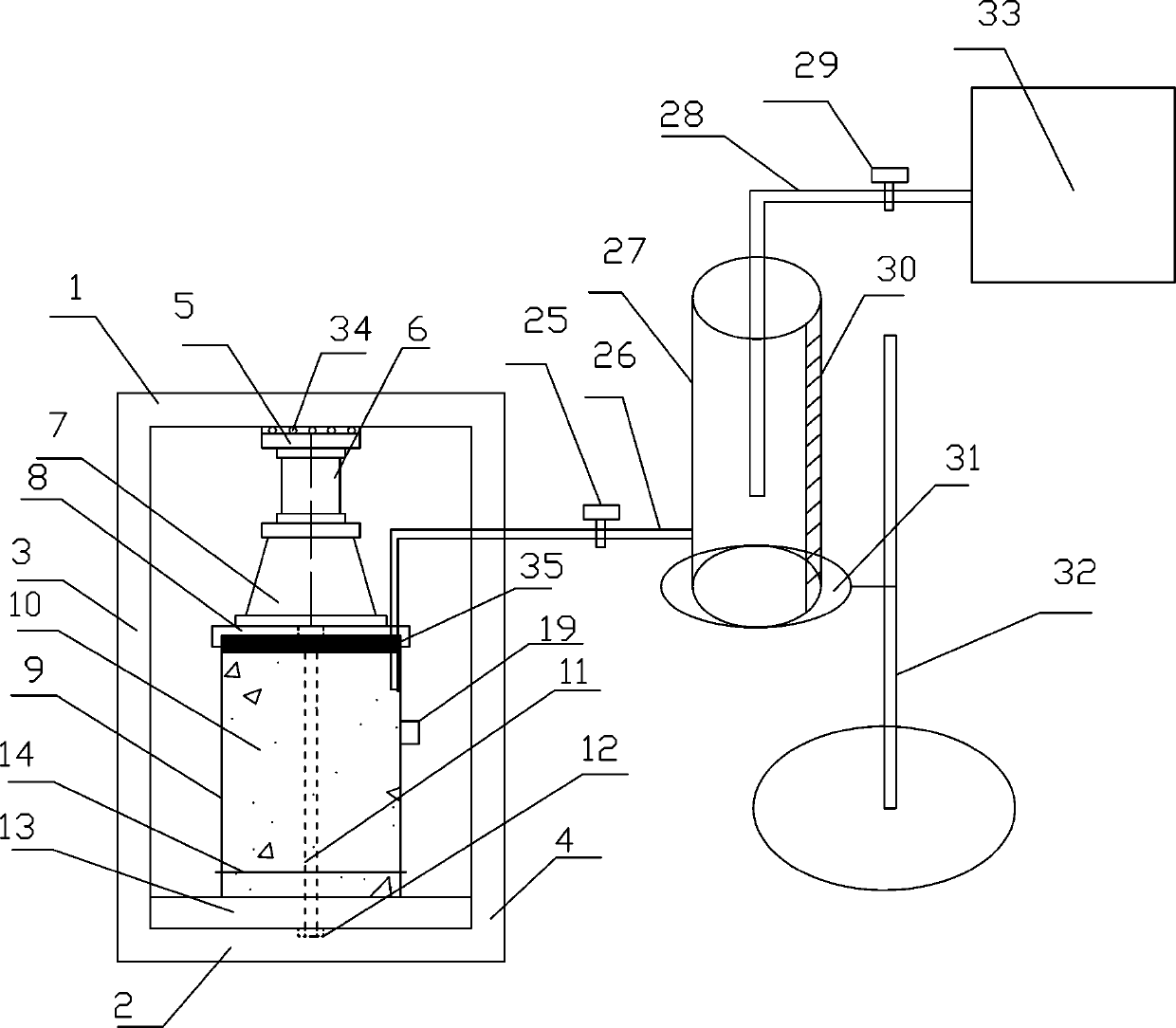

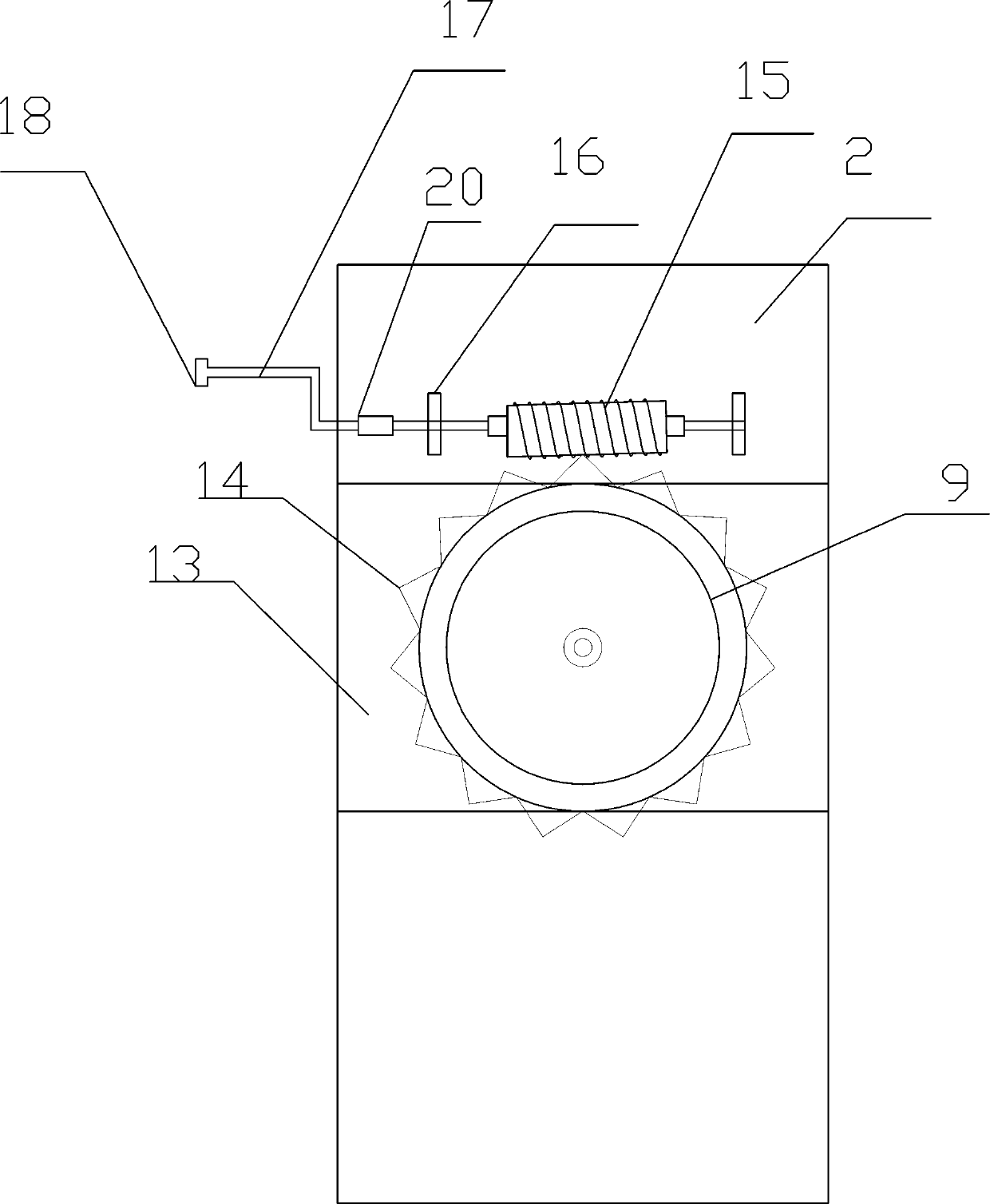

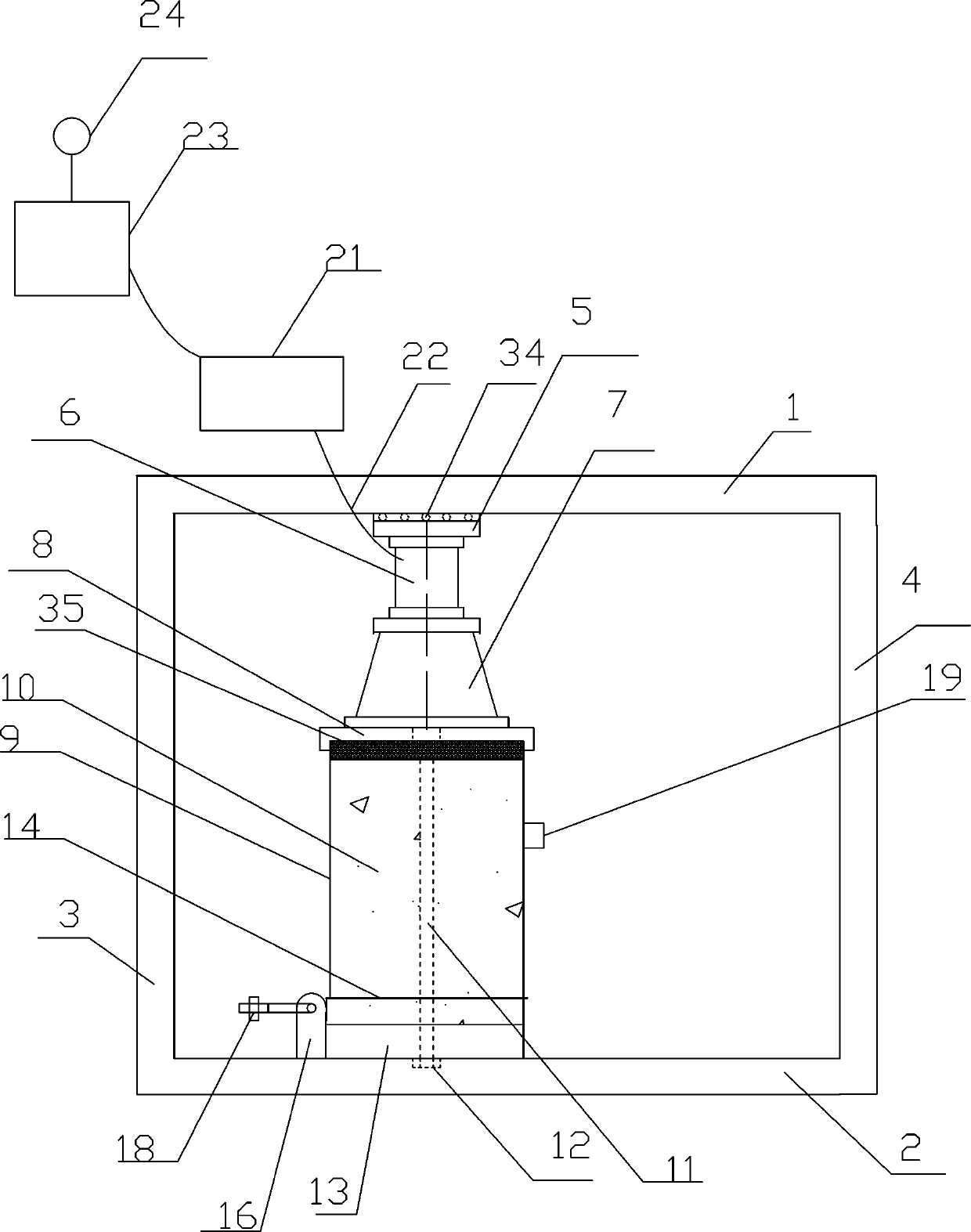

[0041] Such as Figure 1-4 As shown, a torsional shear test device for the original sample of the soil-rock interface includes a load-bearing frame, a sample fixing unit is arranged in the load-bearing frame, a normal stress loading unit is arranged above the sample fixing unit, and a lateral stress loading unit is arranged on the sample fixing unit. There is a circumferential shear unit; there is also an infiltration unit, which is used to supply water to the sample and simulate the torsional shear test of the soil-rock interface in a water-containing state.

[0042] Specifically, the bearing frame includes a top plate 1 , a bottom plate 2 , a left vertical vertical plate 3 and a right vertical vertical plate 4 , thereby forming a closed space for torsional shear tests.

[0043] The sample fixing unit includes a sleeve 9 , a sample 10 , and a rock plate 13 , wherein the sample 10 is placed in the sleeve 9 and the sleeve 9 is placed above the rock plate 13 . The rock plate 13 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap