Fixed standing-wave ratio (SWR) mismatch load

A technology of mismatched load and standing wave ratio, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of difficult debugging, low production efficiency, inconvenient use, etc., and achieve easy debugging, small structural size, flatness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

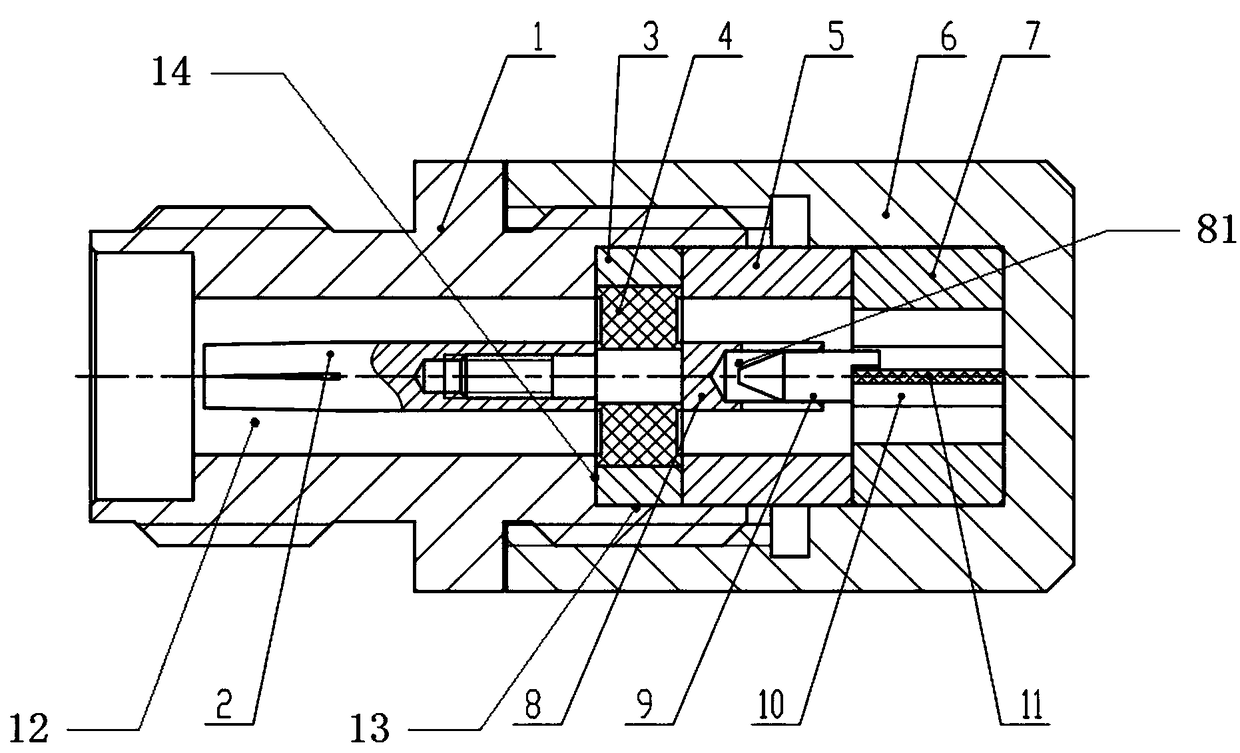

[0021] A fixed VSWR mismatch load, including an outer conductor 1, an inner conductor 8, pins 9, a microstrip sheet 11 and an end cap 6,

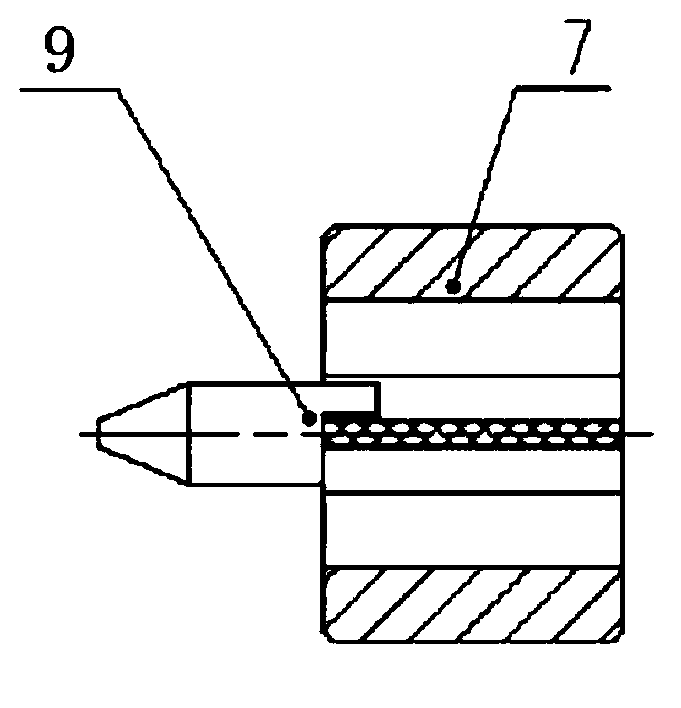

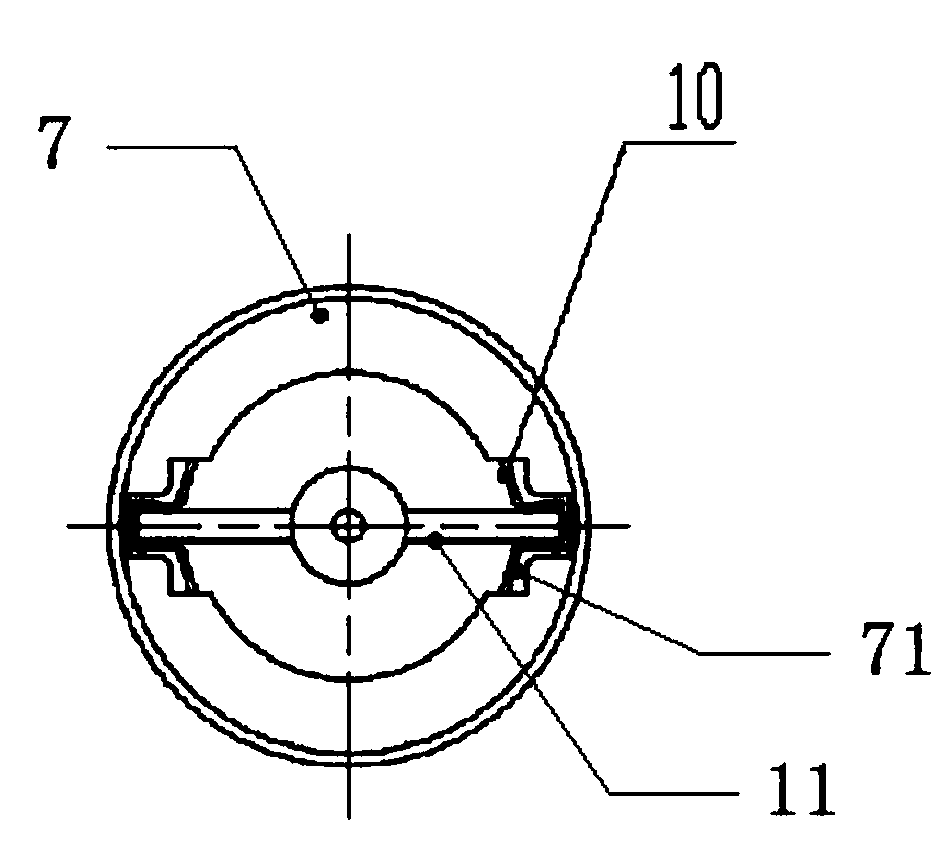

[0022] The outer conductor 1 is a tubular part, the inner conductor is installed and fixed in the inner hole of the outer conductor 1, and the rear end of the inner conductor is provided with a blind hole 81, and the blind hole 81 is adapted to the front end of the pin 9 , the microstrip sheet 11 is arranged at the rear end of the pin 9, the microstrip sheet 11 is fixedly installed in the end cover 6, the end cover 6 is detachably connected with the outer conductor 1, the microstrip sheet 11 The substrate is an alumina ceramic substrate covered with thin-film resistors, the dielectric constant of the alumina ceramic substrate is 9.9, and the thin-film resistor on th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap